U Values and R Values

ASHRAE 90.1 Code Compliance

Take a look at what ASHRAE says about fiberglass and how it performs when placed in steel structures. Whether it is steel stud walls or full steel wall with all the connections, joints, and support beams, the benefits of fiberglass are dramatically reduced by engineering standards because it cannot effectively block the lost or gain of heat.

Testing required to prove the R value:

A. ASTM C 236-89 “Standard test method for Steady-State Thermal Performance of building Assemblies by Means of a Guarded Hot Box”.

B. ASTM 1269 “Differential Scanning Calorimeter” ASTM E1461-92 “Thermal Diffusivity”

ASHRAE 90.1 Code Compliance Statement

When it is colder on one side of an envelope element, such as a wall, roof, floor, or window, heat will conduct from the warmer side to the cooler side. Heat conduction is driven by temperature differences and is a major component of heating and cooling loads in buildings. The building envelope requirements of the 90.1 Code address heat conduction by specifying minimum R-values (thermal resistance to heat flow) for insulation or maximum U-factors (the rate of steady-state heat flow) for building envelope construction assemblies.

U Value (U-factor)

The U-factor is the rate of steady-state heat flow. It is the amount of heat in Btu (British thermal units) that flows each hour through one square foot, when there is a one degree temperature difference between the inside air and outside air. The heat flow can be in either direction, as heat will flow from the warmer side to the cooler side. Steady-state heat flow assumes that temperatures on both sides of a building envelope element (while different) are held constant for a sufficient period of time so that heat flow on both sides of the assembly is steady. The steady-state heat flow method is a simplification, because in the real world, temperatures change constantly. It can, however, predict average heat flow rates over time, and is used by the 90.1 Code to limit conductive heat losses and gains. Because they are easy to understand and use, the terms for steady-state heat flow are part of the basic vocabulary of building energy performance.

Each layer of a building assembly, such as the sheathing and the insulation, has its own conductance, or rate of heat transfer. The conductance for an individual layer is like the U-factor, and it has the same units. The difference is that it is only for a single element or layer. The U-factor includes the conductance of every element of the building assembly, including the air films on the interior and exterior surfaces of the construction assembly. The surface conductances quantify the rate at which heat is transferred between the surface of the construction assembly and the surrounding environment.

For light frame walls, the steady-state U-factors provide an adequate description of heat transfer. For heavy concrete and masonry walls, however, this is only true under constant or average temperature conditions. The dynamic heat storage properties of the concrete and masonry alter the thermal behaviour of the wall, and the U-factor becomes less accurate as a predictor of heat flow rates.

Default U-factors

Precalculated U-factors are provided in this section for typical construction assemblies, including roofs, floors, and doors. These values are calculated using acceptable methods, and may be used for compliance with the code.

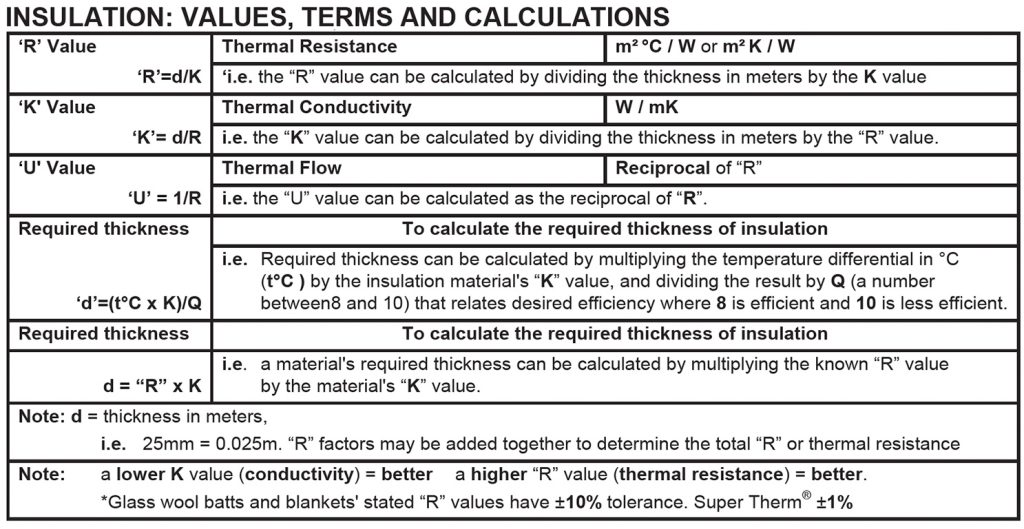

R-Value

R-values are also used to describe steady-state heat flow, but in a slightly different way. The R-value is the thermal resistance to heat flow. A larger R-value has greater thermal resistance, or more insulating ability, than a smaller R- value. The big advantage of R-values is that they can be added together. For homogeneous assemblies, the total R-value of a construction assembly is the sum of the R-values of each of the layers. The layers should include the sheathing and finishes, the insulation and weatherproofing elements, and the surface air films. The U-factor is the inverse of the total R-value.

The R-value is widely recognised in the building industry and is used to describe insulation effectiveness. The insulation R-value is not the total R-value of the wall, however. It only describes the thermal resistance of the insulation material. The RU value of the entire wall assembly can be significantly lower when metal framing penetrates the insulation.

Most construction assemblies include more than one material in the same layer. For example, a wood stud wall includes cavity areas where the insulation is located and other areas where there are solid wood framing members. The wood areas have a lower R-value, and conduct heat more readily than the insulated areas. It is incorrect to neglect framing members when calculating the U-factor for the wall, roof, or floor assembly. The correct U-factor includes the insulation portion of the wall and the U-factors through the solid (or framed) portion of the wall. The 90.1 Code requires that the U-factor of each envelope assembly be calculated taking into account framing and other thermal bridges within the construction assembly.

R-value differences

To determine the effectiveness of insulation with different R-Values, we need to calculate the heat transfer rate through the insulation for each case. The formula for heat transfer through insulation is:

Heat Transfer (Q) = (Temperature Difference) / (Thermal Resistance, R-Value)

Assuming the outside ambient temperature is 30 degrees Celsius and the desired indoor temperature is 20 degrees Celsius, let’s calculate the heat transfer rate for both R-Value scenarios:

- Insulation with R-Value of 5:

- Temperature Difference (ΔT) = 30°C (outside) – 20°C (inside) = 10°C

- Heat Transfer (Q) = 10°C / 5 (R-Value) = 2 watts per square meter (W/m²)

- Insulation with R-Value of 3:

- Temperature Difference (ΔT) = 30°C (outside) – 20°C (inside) = 10°C

- Heat Transfer (Q) = 10°C / 3 (R-Value) = 3.33 watts per square meter (W/m²)

Now, let’s compare the heat transfer rates:

- For insulation with an R-Value of 5, the heat transfer rate is 2 W/m².

- For insulation with an R-Value of 3, the heat transfer rate is 3.33 W/m².

The insulation with an R-Value of 5 is more effective in this scenario because it allows for a lower heat transfer rate compared to the insulation with an R-Value of 3. This means that the insulation with an R-Value of 5 will better resist the flow of heat and help maintain a more comfortable indoor temperature with lower energy consumption for cooling purposes.