R-Value Fairy Tale – The Myth of Insulation Values

One of the fairy tales of our time is the “R-value.” The “R-value” is touted to the consumer to the point where it has taken a “chiseled in stone” status. The saddest part of the fairy tale is the R-value by itself is almost a worthless number.

It is impossible to define an insulation with a single number. It is imperative we know more than a single “R” number. So why do we allow the R-value fairy tale to be perpetuated? We don’t know if anybody knows. It obviously favours fibre insulation. Consider the R-value of an insulation after it has been submersed in water or with a 30 kilometre per hour wind blowing through it. Obviously the R-value of fibre insulations would go to zero or less. Under the same conditions, the solid insulations would be largely unaffected. Again R-value numbers are “funny” numbers. They are meaningless unless we know other characteristics.

None of us would ever buy a piece of property if we knew only one dimension. Suppose someone offered a property for $10,000 and told you it was a seven. You would instantly wonder if that meant seven acres, seven square feet, seven miles square, or what. You would want to know where it was – in a swamp, on a mountain, in downtown city. In other words, one number cannot accurately describe anything. The use of an R-value alone is absolutely ridiculous.

Yet we have Code bodies mandating R-values of 2.5 or 4 or 5 (A fibre insulation having an R-value of 4 placed in a house not properly sealed will allow the wind to blow through it as if there were no insulation. Maybe the R-value is accurate in the tested material in the lab, but it is not even remotely part of the real world. We must start asking for some additional dimensions to our insulation. We need to know its resistance to air penetration, to free water, and to vapour drive. What is the R-value after it is subjected to real world conditions?

The R-value is an abstract figure created to express how well a material resists heat loss or heat gain. It is calculated by taking the material’s thermal conductivity (k-value, measured in W/m·K) and dividing it into 1. The k-value itself is the real measurement of how much heat flows through a material per metre of thickness.

Test to Determine the R-Value

The test used to produce the “R” value is an ASTM test. This ASTM test was designed by a committee to give us measurement values that hopefully would be meaningful. A major part of the problem lies in the design of the test. The test favours the fibre insulations – fibreglass, rock wool, and cellulose fiber. Very little input went into the test for the solid insulations, such as foam glass, cork, expanded polystyrene, urethane foam and now ceramic insulation coatings such as Super Therm®.

The test does not account for air movement (wind) or any amount of moisture (water vapor). In other words, the test used to create the R-value is a test in non-real-world conditions. For instance, fiberglass is generally assigned an R-value of approximately 3.5. It will only achieve that R-value if tested in an absolute zero wind and zero moisture environment. Zero wind and zero moisture are not real world. Our houses leak air, all our buildings leak air, and they often leak water. Water vapour from the atmosphere, showers, cooking, breathing, etc. constantly moves back and forth through the walls and ceilings. If an attic is not properly ventilated the water vapour from inside a house will very quickly semi-saturate the insulation above the ceiling. Even small amounts of moisture will cause a dramatic drop in fibre insulation’s R-value – as much as 50 percent or more.

Multiple ASHRAE and ASTM studies on roof insulation show the same pattern: once fibrous or open-cell insulation gets damp, its real-world R-value collapses. At about 0.25–0.5% moisture by volume, glass fibre roof insulation can see heat flow increase by more than 50%, and around 1% moisture can more than double heat flow in summer – effectively halving the R-value. Massachusetts Institute of Technology.

Earlier ASTM field work and US laboratory studies on flat roofs found that roof insulations with around 20% moisture content carried at least twice the heat flow of dry insulation, confirming that wet insulation can lose more than half of its effective thermal resistance. ASTM International.

Super Therm® is the non-hygroscopic alternative to traditional insulation because it doesn’t absorb moisture, doesn’t trap condensation and doesn’t lose performance when the building envelope gets wet. Traditional fibreglass and mineral wool collapse the moment they take on moisture, but Super Therm® blocks heat at the surface without relying on air gaps or dry cavities. It keeps its thermal performance in real-world conditions – humid, damp, coastal, or high-condensation environments – where conventional insulation fails.

Vapour Barriers

A vapour barrier exists for one reason: stop warm, moist indoor air from moving into the insulation layer, where it condenses and saturates the material. When that happens, you get three failures:

- R-value drops

Wet fibreglass or mineral wool loses a huge percentage of its insulation value. Moisture increases conductivity and destroys the performance you paid for. - Mould and decay

Moist, stagnant insulation becomes a mould factory. It also rots timber framing and corrodes metal components. - Interstitial condensation

Moisture gets trapped inside the wall where you can’t see it. Over months or years it causes structural and health problems long before anyone notices.

In short: insulation only works when it’s dry. A vapour barrier is there to keep water vapour out of the insulation so the R-value remains intact and the building envelope doesn’t rot from the inside out.

Obviously, it changes from summer to winter – even from day to night. Even if it is below zero outside, the inside of an occupied house is certainly the warm side. During the summer months, when the sun is shining, very obviously the warm side is the outside. Sometimes the novice will try to put vapour barriers on both sides of the insulation. Vapour barriers on both sides of fibre insulation generally prove to be disastrous. It seems the vapour barriers will stop most of the moisture but not all. Small amounts of moisture will move into the fibre insulation between the two vapour barriers and be trapped. It will accumulate as the temperature swings back and forth. Super Therm® is also a vapour barrier therefor it is always facing the warm side.

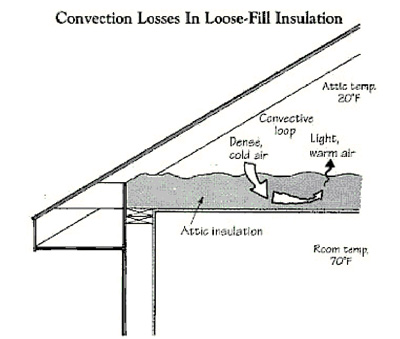

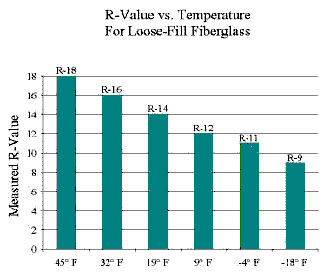

At very cold temperatures, when the temperature difference across the roof space insulation reaches a certain critical point, convection within the insulation can reduce R-value.

We understand air penetration through the wall of the house. In some homes when the wind blows, we often can feel it. But what most people, including many engineers, do not realise is that there are very serious convection currents that occur within the fibre insulations. These convection currents rotate vast amounts of air. The air currents are not fast enough to feel or even measure with any but the most sensitive instruments. Nevertheless, the air is constantly carrying heat from the underside of the pile of fibres to the topside, letting it escape or carrying it from the topside to the underside and letting it penetrate. If we seal off the air movement, we generally seal in water vapour. The additional water often will condense (this now becomes a source of water for rotting or rusting of the structure and the growth of mould which is an air quality / health issue – think of the “Leaky Condo” fiasco ). The water, as a vapour or condensation, will seriously decrease the insulation value – the R-value. The only way to deal with a fibre insulation is to ventilate. But to ventilate means moving air which also decreases the R-value.

Leaky-building failures in New Zealand, Canada and now Australia all point to the same core issue: once water penetrates the building envelope, the entire wall system begins to break down. Cladding systems with poor drainage paths, inadequate ventilation and flawed detailing trap moisture inside the wall cavity. That moisture is absorbed by the framing, linings and, critically, the insulation. Because bulk insulation only performs when dry, even small amounts of trapped moisture can strip away its thermal resistance, trigger mould, cause decay and drive internal humidity into the living space. Buildings that were compliant on paper quickly lose their thermal performance in practice.

The article shows that the cost of these failures is enormous – billions of dollars in New Zealand and rising in Australia – driven by the same pattern of hidden moisture, compromised insulation and a building envelope that cannot dry. Once the insulation becomes saturated, the wall can no longer manage heat, air or moisture properly, setting off a cycle of deterioration. The lesson is blunt: insulation is not the problem by itself, but insulation inside a poorly detailed, moisture-prone envelope becomes a liability. If the building is not designed to stay dry, the insulation will fail long before its rated lifespan.

Air Penetration

The filter medium for most furnace filters is fibreglass – the same spun fibreglass used as insulation. Fiberglass is used for an air filter because it has less impedance to the airflow, and it is cheap. In other words, the air flows through it very readily. It is ironic how we wrap our house in a furnace filter that will strain the bugs out of the wind as it blows through the house. There are tremendous air currents that blow through the walls of a typical home. As a demonstration, hold a lit candle near an electrical outlet on an outside wall when the wind is blowing. The average home with all its doors and windows closed has a combination of air leaks equal to the size of an open door. Even if we do a perfect job of installing the fibre insulation in our house and bring the air infiltration very close to zero from one side of the wall to the other, we still do not stop the air from moving through the insulation itself vertically both in the ceiling and the walls.

The best-known solid insulation is expanded polystyrene. Other solid insulations include cork, foam glass, polyisocyanate or polyisocyanurate board stock and ceramic insulation coatings. Each of these insulations is ideally suited for many uses. Foam glass has been used for years on hot and cold tanks, especially in places where vapor drive is a problem. Cork is of course a very old standby often used in freezer applications. EPS or expanded polystyrene is seemingly used everywhere from throw away drinking cups and food containers to perimeter foundation insulation, masonry insulations, and more. Urethane board stock is becoming the standard for roof insulation, especially for hot mopped roofs. It is also widely used for exterior sheathing on many of the new houses. All of the solid insulations will perform far better than fibre insulations whenever there is wind or moisture involved. Super Therm® will perform the best of all.

Most of the solid insulations are placed as sheets or board stock. They suffer from one very common problem. They generally don’t fit tight enough to prevent air infiltration. It does not matters how thick these board stocks are if the wind gets behind them. We see this often in masonry construction where board stock is used between a brick and a block wall. Unless the board stock is actually physically glued to the block wall, air will infiltrate behind it. In this case, as the air flows through the weep holes in the brick and around the insulation it is rendered virtually useless. Great care must be exercised in placing the solid insulations. The brick ties need to be fitted at the joints and then sealed to prevent airflow behind the insulation.

The only commonly used solid insulations that absolutely protect themselves from air infiltration are the spray-in-place insulations ie. SPF or CERAMIC INSULATION COATINGS such as Super Therm®. When properly applied the bonding will effect a total seal. This total seal is almost impossible to overestimate. In my opinion most of the heat loss in the walls of the home have to do with the seal rather than the insulation.

For physical reasons, heat does not conduct horizontally nearly as well as it does vertically. Therefore, if there were no insulation in the walls of the homes, but an absolute airtight seal, there would not necessarily be a huge difference in the heat loss. This would not be the case if the insulation were missing from the ceiling. Air infiltration can most effectively be stopped with spray-in-place insulations such as Super Therm®. It is the only material (properly applied) that will fill in the corners, the cripples, the double studs, bottom plates, top plates, etc. The R-value of a material is of no interest or consequence if air can get past it.

“There is a problem with loose-fill fibreglass attic insulation is cold climates. It appears that, as attic temperature drops below a certain point, air begins to circulate into and within the insulation, forming “convective loops” that increase heat loss and decrease the effective R-value. At very cold temperatures (-20°F / -28.89°C), the R-value may decrease by up to 50%.”

In full-scale attic tests at Oak Ridge National Laboratory, the R-value of 6 inches of cubed loose-fill attic insulation progressively fell as the attic air temperature dropped. At -27.78°C (-18°F), the R-value measured only R-9 (USA). The problem seems to occur with any low-density, loose-fill fibrous insulation.

R-value tables are truly part of the “Fairy Tale.” They show the solid and the fibre insulations side by side, implying they can be compared. The fact is, without taking installation conditions into account, comparisons are meaningless. Spray-in-place insulation such as Super Therm® provides its own vapor barrier, water barrier, and wind barrier. None of the other insulations are as effective without special care taken at installation. The fibre insulations must be protected from wind, water and water vapor. Again the tables need a second table to state installation conditions.

Understanding the two purposes of insulation gives a standard to measure the insulations:

I. Heat loss

There is a little understood part about insulation that needs to be covered. There is a substantial difference between insulation for temperature control and insulation for heat loss control. More insulation is not necessarily cost effective. There is a point where more insulation is pointless from a total heat loss perspective.

Where circumstances demand thinner walls or roofs, Super Therm® – with its superior insulating capability – makes it possible to reduce the thickness of the insulation component with no loss of thermal resistance. Or the thermal resistance of an assembly can be increased without enlarging the size of the member. Super Therm® helps to offset the design restrictions imposed by the fact that most building materials are constant in thickness and weight.

Thermal Diffusivity and Heat Sinks

When Super Therm® is applied to the exterior surface of a high-mass material such as concrete, brick or masonry, the effective thermal resistance of the assembly increases significantly. These materials act as heat sinks because they can absorb and store large amounts of heat. Concrete, brick, adobe, earth and water all have high heat capacity. They don’t insulate; they store heat. Their behaviour is governed by thermal diffusivity – the rate at which heat moves through a material – not by thermal resistance.

Here’s the simple explanation. As outdoor temperatures swing from hot to cold, heat-sink materials absorb and release energy slowly. Their high heat capacity means they never fully track the daily temperature cycle. Instead, their internal temperature “averages out” over longer periods. A large thermal mass may average over days, weeks or even months. This is why traditional adobe buildings with walls 60–180 cm thick remain relatively stable inside: daytime heat is absorbed slowly, and by the time the heat wave moves through the wall, it is already night and the temperature has dropped, so the stored heat flows back outward.

Thermal mass moderates temperature, but it is not insulation. Adobe, concrete and brick have very low R-values. They slow heat movement because of their low thermal diffusivity and long time lag, not because they resist heat transfer the way an insulation material does.

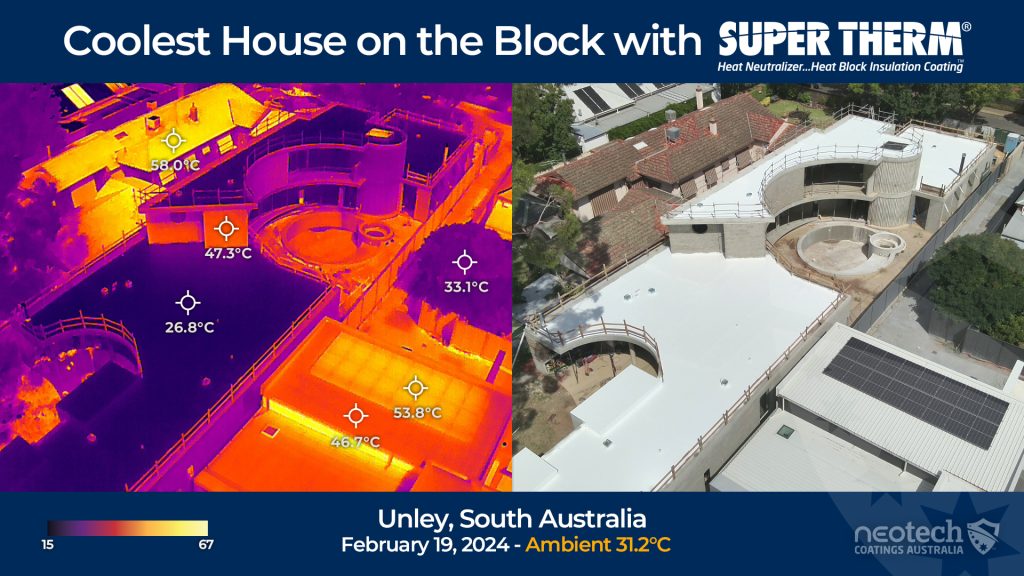

Super Therm® changes the equation. By blocking solar radiation at the surface, it prevents the heat sink from loading up in the first place. With the heat load removed, the mass of the wall is no longer driven by external temperature swings, which effectively increases the overall R-performance of the assembly. The coating thickness above 250 microns (0.25 mm) is not significant; the heat-blocking performance is achieved at this dry film thickness, which is standard for most construction applications.

The simple explanation for the way it works is: As the temperature of the atmosphere cycles from cold to hot to cold to hot the heat sink absorbs or gives up heat. But because the heat sink can absorb so much heat it never catches up with the full range of the cycle. Therefore, the temperature of the heat sink tends to average. Large heat sinks will average over many days, weeks or even months.

An example is the adobe hacienda with its 2 to 6 foot thick walls. By the time the adobe walls begin to absorb the daytime heat it is nighttime and the same heat then escapes into the cooler night. Therefore the temperature would average. Because the mass of the adobe is so large the temperature averages over periods of months. Adobe acts as a bulk insulation even though adobe has a minimal “R” value.

Super Therm’s thickness beyond 250 microns/10 mils DFT is practically immaterial. We use 250 microns/10 mils DFT for most of our applications.

II. Surface temperature control

Surface temperature control is the second reason for insulation. In many cases it is the most important reason for the insulation.

Buildings insulated with 250 microns/10 mils DFT of Super Therm® would hold the temperatures properly, just as well as the buildings insulated with 500 microns/20 mils DFT. The difference came in the condensation. Ice Arena’s and cold storage’s, for example, are at very high humidity levels. Surfaces coated with the 250 microns/10 mils DFT of Super Therm® would sometimes still experience condensation and would require additional thickness to control depending on the dew point differential ie. the surface temperature of a liquid ammonia line or tank at – 35°C to -70°C and the ambient surrounding temperature and other environmental conditions such as relative humidity.

Underground housing – surface temperature control vs. heat loss control. see “Insulating Basement Walls“

Most underground housing is in trouble from mould and mildew growth. The cause is not enough insulation to control interior surface temperatures. Rarely is there a problem with total heat loss. Water vapour condenses on the surface allowing mould to grow. Mould makes people sick. The only solution is lots of insulation for temperature control and ignore total heat loss.

Our experience is that R-value tables can be used as indicators. They need modifications to make them equal to real world conditions. There needs to be allowances made. They must show equivalents. These equivalents will be more like 10/1000″ of ceramic insulation coating equal to six inches of fibreglass or one inch of spray-in-place urethane equal to four inches of fibreglass, in a normal installation. Footnotes to the table will need to define degradation of insulations in real world conditions. Only then will the “R-value” Fairy Tale become a real world success story. These real world conditions have finally started to be addressed in the ASHRAE 90.1 CODE COMPLIANCE.