Corrosion Protection

The Australasian Corrosion Association released its “Impact of Corrosion in Australasia” report, estimating that the country could spend up to roughly $78 billion per year on the management and mitigation of corrosion on its national infrastructure assets. (Source).

According to the report, corrosion effects can contribute between 3.5% to 5.2% of global domestic product and is most commonly caused by water, carbon dioxide and hydrogen sulfide, but can also be aggravated by microbiological activity. In its report, Resona extrapolated these figures to reach its high estimate of $78 billion per annum on corrosion-affected asset remediation.

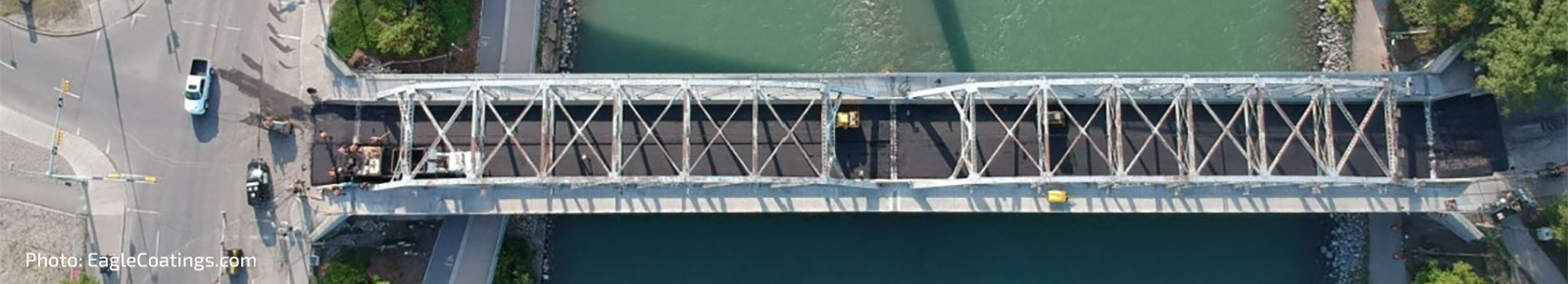

Rust Grip®

The 6,780+ psi permanent rust proofing solution

Rust Grip® Is a one-part polyurethane coating that combines with atmospheric moisture to cure. Upon curing, Rust Grip® provides a protective coating of superior adhesion, flexibility and abrasion/impact-resistance. It is resistant to chemical solvents and acid splash.

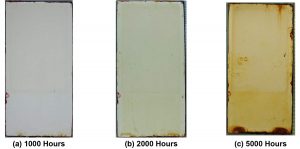

Rust Grip® has passed over 15,000 hours of Salt Spray testing (pdf) equivalent to 30 years.

Originally designed for metal surfaces, Rust Grip® demonstrates excellent adhesion to wood, concrete, fiberglass and many other substrates. Rust Grip® is designed for the encapsulation of and adherence to tightly-bonded surfaces of lead-based and other toxic paints as well as rusted surfaces.

Rust Grip® works with HPC and HSC to manage issues relating to Corrosion Under Insulation (CUI) > Learn More about Rust Grip >

Moist Metal Grip

Long lasting corrosion protection in a moist environment

Moist Metal Grip is a tough adherent, 2 component Epoxy coatings, which produce hard, yet flexible coating films. These epoxy products will demonstrate excellent chemical and solvent resistance when utilised in harsh atmospheres, and will also provide outstanding water and humidity resistance.

These coatings will adhere tenaciously to a variety of substrates, such as carbon steel (phosphated or non-phosphated), wood and concrete. These products can be utilised in DTM (direct-to-metal) applications, with excellent success, as they have been fortified with a very efficient, non-toxic, rust inhibitive pigment > Learn More >

Lining Kote UHS

Protect against the harshest acids, bases, chemicals and solvents

Lining Kote UHS is a two-part pigmented epoxy coating, which will produce a hard, tough coating film. Designed to for use on the interior of tanks, this epoxy coating was built to resist the toughest acid, chemical or solvent environments. Learn More >