Super Therm® Ceramics Thermal Insulation Coating

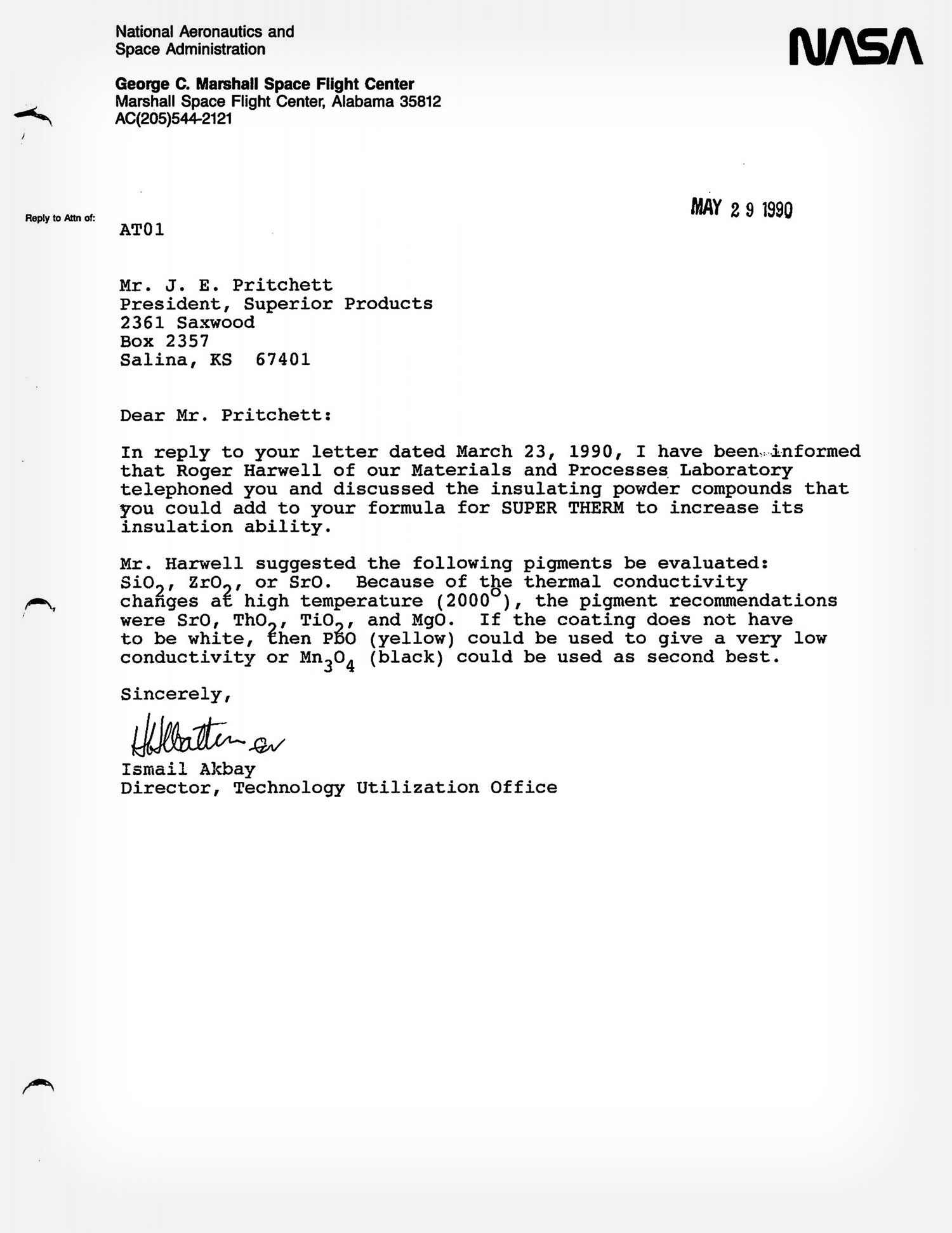

Super Therm® is a water-borne coating developed with NASA has proven an outstanding heat block in harsh weathering conditions. Below J.E. Pritchett outlines how he and SPI Coatings worked with NASA to commercialise this technology and describe successful applications worldwide.

Super Therm® tested and approved by NASA in 1989-1995!

There are many coating companies claiming association with NASA for the development of a coating product. None can offer proof of this claim, no testing, no actual association with any NASA lab work and results or proof. SPI did work with the assistance of NASA lab personnel for testing and results and help in locating ceramic compounds from sources for JE Pritchett, the SPI researcher to do the Trial and Error R&D for now 30 years. J.E. was a featured speaker at the NASA technology conference in Chicago in 1995 on Super Therm®.

The ceramics used in Super Therm® do not conduct heat…reduce the emissivity, therefore, you will not feel any heat even when those ceramics are burned on your hand with a burner (1300℃).

Physics show that ceramics melts at thousands of centigrade unlike metal, plastics and fibreglass and ceramics do not release poisonous chemicals. Ceramics are a natural thermal barrier.

Getting the sequence of ceramics is the key to a quality, high performance coating.

Single ceramic beginnings

Since the 1970s and 1980s, the reflective coating concept was very interesting in the idea of using a single ceramic component to reflect surface heat from sun. Radiation was thought to be the best way to solve heat load. Within a couple of years, this idea that surface reflection would solve any heat load problem on surfaces and discovered to be wrong due to the fact that the coating would become dirty and stop reflecting…the answer was in multi-ceramics.

Rethinking ceramic coatings

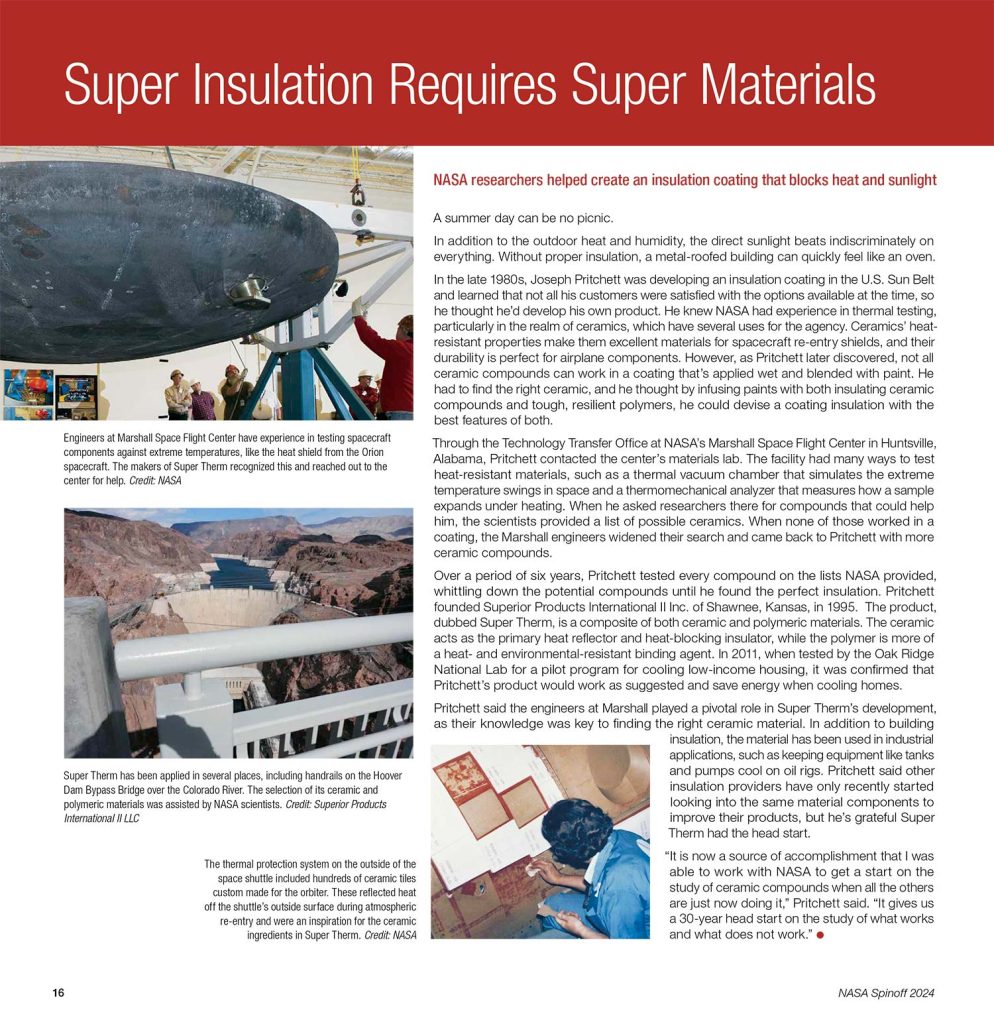

As the established reflective companies continued to promote and sell this technology, J.E. Pritchett (Inventor and President of SPI Coatings) visited with his Uncle that worked at Red Stone in Alabama that was connected to NASA. He in turn guided him to the engineers that developed and designed the tiles for the shuttle. In working with these engineers for a short time, J.E. found that the ceramics used for the tiles would not work in a coating product because when the environment of the compound changed drastically from dry to wet it mixed with other compounds.

SPI holds the distinction of having scientific research and industry testing relationships with major corporations from around the world including working with NASA for 6 years on the development of Super Therm®.

Since none of this type of information could be found in any research books, J.E. began to develop and set up Trial and Error procedures to test ceramic compounds in a base coating. The initial thought was that this would take 6 months and the compounds could be found to perform as planned and the coating completed. In the first 6 months, the initial sources were found. The first year, more sources were found. In the fourth year, it was finally decided what to look for in density, crystalline structure and material compound.

Finding the right compounds that will continue to block heat when formulated into a coating is the result of 30 years of R&D. Yearning to find individual compounds that will combine together and form a heat shield from all 3 heat waves, this ultimately reduces heat load.

The creation of Super Therm® was conceived by J.E. when trying to develop a heat shield for space shuttles using advanced ceramic heat block technology that resisted extreme heat fluctuations could be more easily managed. J.E. was a specialist ceramics speaker for NASA in Chicago in 1995 regarding Super Therm®.

After 30 years and over 4000 ceramic compounds, it was found which compounds actually do work in any environment, mixed with other compounds that will improve the performance, which compounds are good for radiation heat in the ambient atmosphere, which work over high temperature surfaces to block and hold heat and which are good for fire control. Ultimately 4 ceramics with the greatest ability of radiation reflection and the smallest heat conductivity were ultimately selected to go into the secret sauce of Super Therm® High Performance Heat Block Coating.

Super Therm® is awarded NASA’s highest rating as non-toxic, passed flammability tests to receive an A rating (highest non-flammable rating). It was passed with a “0” rating out of 100 for the ‘Flame Spread Index” and “Smoke Spread Index”.

Super Therm® ceramic coating manufacturers, SPI Coatings accomplished their most important task – the coating provided not only the heat reflection like other ceramic “heat – reflecting” coatings but also blocked most of the heat transfer. 96.1% Heat Block – outstanding!

NASA Test Results

J.E. was a featured speaker at the NASA technology conference in Chicago in 1995 on Super Therm®