Rust Grip®

Rust Grip® No More Corrosion! Over 20 Years Rust Protection!

Rated No 1: Rust Grip® is a high performance, tough, aluminium based easy, moisture cured polyurethane encapsulation coating; corrosion, lead paint, asbestos and bio-hazards.

Aluminium; Not Zinc is the future!

Technical Data Sheet (pdf)

Application (pdf)

Rust Grip® Application Instructions

Rust Grip® ULVOC SDS

Rust Grip® Brochure

Imagine: 3 days work in a single day, at half the price and double the corrosion protection performance!

Think it’s too good to be true…it’s possible with Rust Grip®!

Transmission tower refurbishment around the world with Rust Grip®

Rust Grip® was specifically developed in the field to stand up against the harshest environments demonstrating excellent performance and a paradigm shift in corrosion coatings technology. Rust Grip® adds 6780psi / 470 bar surface tensile strength to a surface including corroded steel surfaces, concrete, porous or solid surfaces. It is a single component and easy to apply.

Rust Grip® has a history in oil/gas, railway tracks and equipment, truck bodies and frames along coastal areas, farming equipment, animal facilities, heavy industries. Wherever it is applied, it “encapsulates” the surface by sealing off any air and moisture penetration by having only a 0.24 permeability. Very unique industrial grade coating for stopping corrosion development and gives long term asset protection.

Rust Grip® is a tough, one-part, moisture-cure polyurethane coating that absorbs atmospheric moisture to cure. It is patented and loaded with unique aluminium pigments (not zinc) for strength and is also resistant to chemical solvents and acid splash.

As a solvent, Rust Grip® completely fills the pits, cracks and pores of the metal substrate unlike a surface topical glue coatings, then using the atmosphere anchors in, cures, seals and encapsulates against any possibility of outside air, moisture or minerals from entering the pores and attacking the surface and causing further corrosion or penetration of any kind.

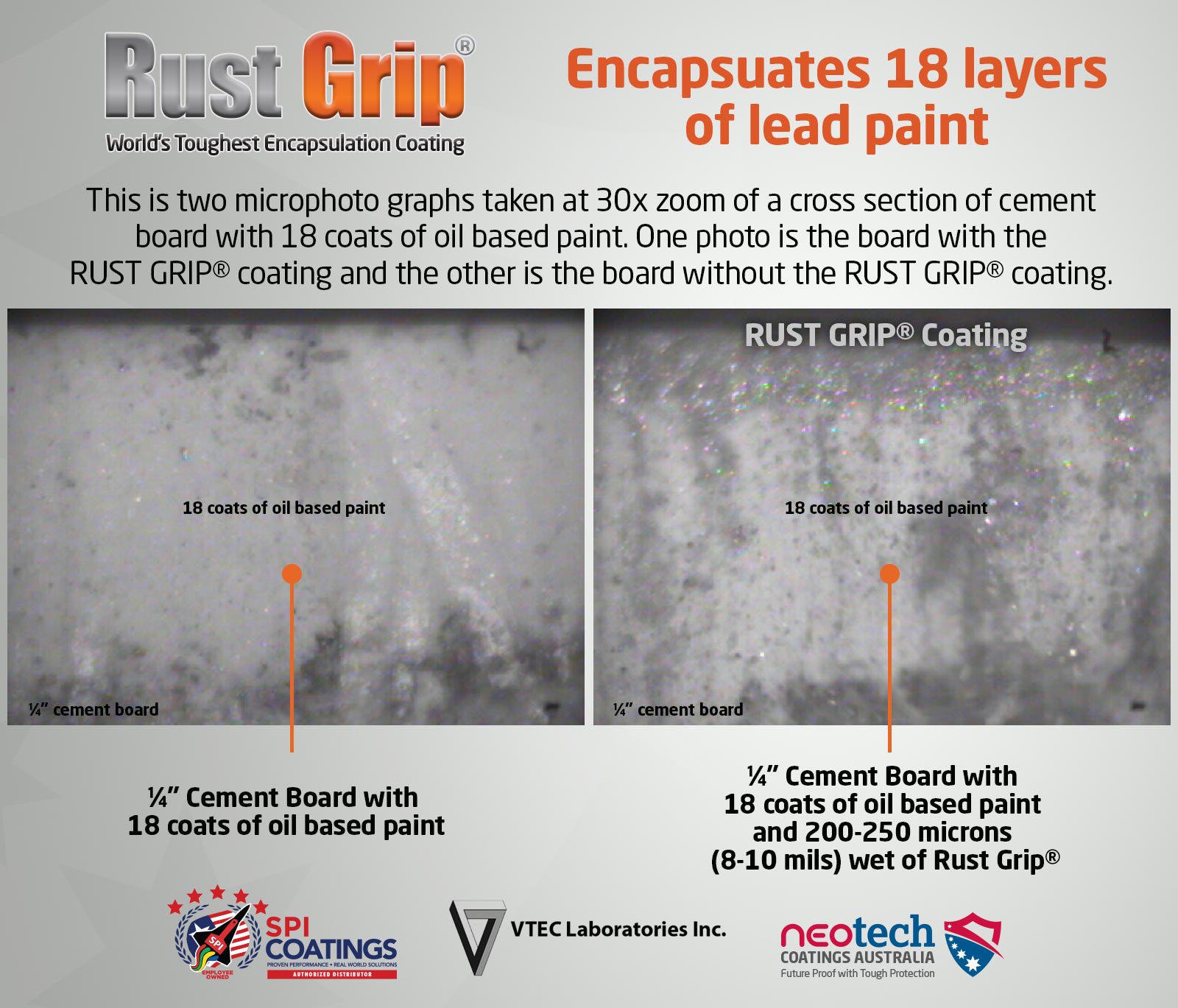

Rust Grip® is tested to encapsulate:

- Corrosion – including Flash, Mill Scale and Pack Rust

- Lead-based paint

- Asbestos

- Bio-hazardous materials

Rust Grip® may be applied to metal, concrete, fibreglass or wood and is extremely easy to use, fast and labor saving. Upon curing, Rust Grip® provides a very, very tough protective coating of superior adhesion and flexibility, and is resistant to abrasion and impact and can be used as a primer or as a one-coating system and is patented to encapsulate lead-based paints, asbestos and bio-hazards. It can be applied over pressure-washed, completely dry flash rust and firmly bonded commercial paints. In most cases, a white or near-white blasting is not required. A light to medium surface rust is preferred as the profile.

Rust Grip’s coating premium advantages are:

- One-Coat System

- Limited Surface Preparation

- Encapsulation

- High Surface Tensile Strength

Rust Grip® offers a simple solution for true encapsulation. A one-coat system that can be applied over a variety of surfaces that meets or exceeds stringent registrations, certifications and testing is truly a paradigm shift that lasts over 20 years. We know you’ll love the results!

Rust Grip® Rated No. 1 by the Society of Petroleum Engineers

A long-term lab and field study by Chevron and Workstrings International published by the Society of Petroleum Engineers, tested 18 leading coatings on drill pipes for eight years. Drill pipes are the toughest environment anyone can ever imagine and Rust Grip® was the top performer. In that paper they highlight the cascading benefits that came from solving the corrosion problem. You solve the corrosion problem, that’s already millions of dollars in savings and then because you’re not having to swap out these drill pipes so often, you’re saving millions in logistics.

“Beyond the goal of eliminating corrosion and pitting-related damages, the introduction of externally coated completion tubulars has facilitated a paradigm shift in the way operators manage rental completion tubulars.”

“This coating system provides a trouble free solution and significant cost savings to the operator and pipe rental company through reduction in pipe repairs and damages; loss of capital assets; and rig time due to pipe issues, fluid issues and corrosion issues.”

“The savings realized in connection repairs alone is estimated to exceed $250,000 per well.”

Why Rust Grip® is the World’s Best Corrosion and Encapsulation Coating

- Rust Grip® used in Australia since 1997

- Single Component – No mixing part A & B; no pot life, no catalyzation

- One-Coat System

- Fast Cure – humidity accelerates curing – ie over 40% humidity 3 coats in a day – micro climate is the key

- Surface Tolerant – Unique for a Polyurethane Rust Grip® on any surface. Minimal surface preparation. Excellent for minimally prepared surfaces, ie. no sandblasting is needed many times

- Embeds and Encapsules; Not just a surface coating

- Limited Surface Preparation

- Self Priming – “Three coats in one” system

- 1 Product shows up to the job site

- Strength – Non leafing aluminium metallics

- Permeability Rating – 0.24 (below 0.5 is excellent)

- UV Protection

- EPA Approved

- Surface Tensile Strength – 6,780+ psi (478 bar) surface tensile strength. It makes an excellent floor coating

- No More Zinc – Aluminium is a stronger and better long-term investment

- Easy to Apply – Brush, Spray or Roller

- Endures 29,700 rub cycles without exposing existing lead based paint

- Higher Surface Temperature – 60°C (Zinc has maximum temperature at 50°C) – more time for application in the heat

- Protects – steel, aluminium, concrete, wood, fibreglass, lead-based paints, and other substrates

- Moisture Barrier – that stops water penetration, prevents corrosion and surface deterioration, and repels dirt, mould, and mildew

- Long Shelf Life – 3 years if unopened

- Patented for encapsulating bio-hazardous materials – (asbestos, lead-based paint, and many hazardous materials) and existing rusted surfaces certified (ASTM E1795) Biohazard Encapsulator

- Breaks The Rules – Minimum Surface Preparation = Better Results

- No Hot Permit Required – (60% of the cost reduced in the surface preparation removing clean up, containment, sound as factors)

- Use in Dangerous environments – Use No Spark Hand tools for preparation of Corrosion and High Pressure Water 6000+ psi removes loose corrosion

- Class A fire coating – In case of fire, Rust Grip® will help to prevent spread of, and will not contribute to the fire

- 20+ year lifespan – under normal conditions

- Passed 15,000 hours (= 30 years) of salt spray testing which far exceeds the marine specifications with a perfect 10 score with no corrosion development (ASTM C117)

No Air, no Moisture = no Corrosion!

Rust Grip® – The Paradigm Shift Corrosion Coating

Some Companies using Rust Grip® Globally

Rust Grip® not only generates barrier protection, but also galvanic protection and encapsulation of the substrate. This moisture-cured polyurethane coating has been used successfully in the harshest environments; chemical fields, oil fields, marine, oil rigs and in areas that demand resistance to the corrosive effects of day-to-day exposure.

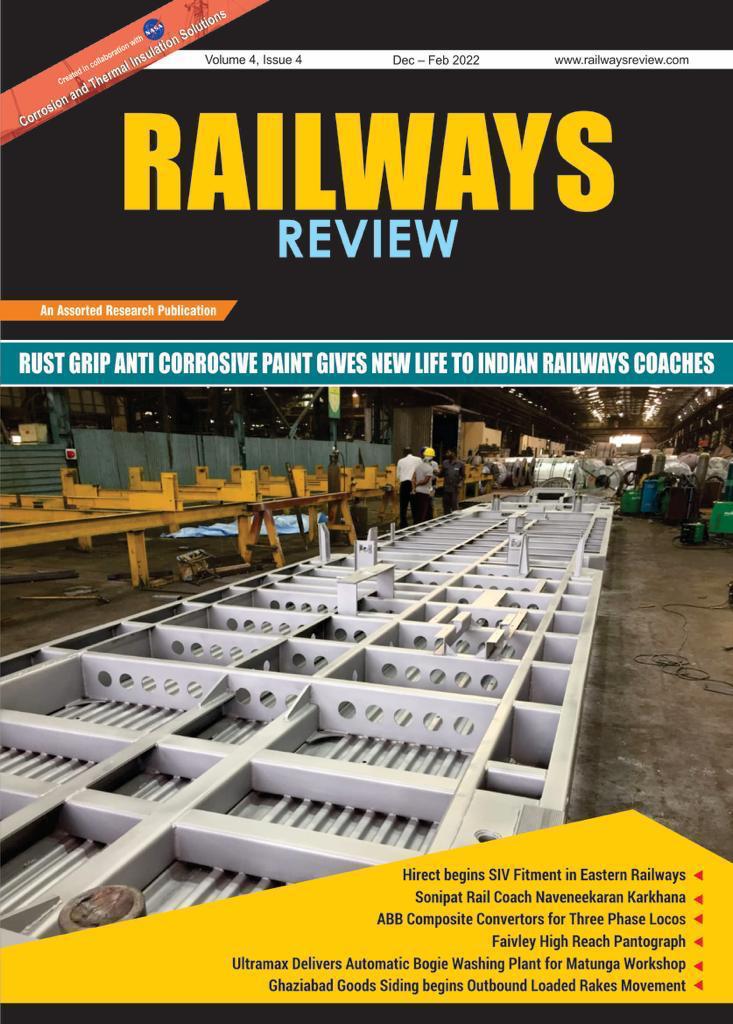

Rust Grip anti corrosive coating gives new life to Indian Railways coaches

Rust Grip, ‘One Part’ universal anti corrosive paint system gives a new life to LHB coaches at Sonipat Rail Coach refurbishment facility.

Rust Grip was selected by RCNK to have a longer asset life of the LHB coaches for the coach structure, precisely the under frames, bogie bolsters and the end walls.

”Rust Grip optimally does away with corrosion. Further, given its properties of one pack system it drastically curtails application costs and time. With the given, one pack characteristics, more numbers of coaches and wagons can be refurbished. This commensurately results higher the rolling stock out turn volumes as there are capacity constraints at most of the Indian Railway workshops given the very high work load at present”. Mentions Mr. Anil Kumar.

More information see RIT Coatings India or read the article (pdf). See how Super Therm is used on Indian Railways.

Outperforms 3-coat system

- On pull testing of system, 3-coat system pulls at 150 psi (10.5 bar)

- Rust Grip® system pulls at 580 – 1480 psi (40.6 – 103.6 bar)

- Hardens to 6,780 psi (47.3 MPa / 478 bar) Surface Tensile Strength

- Replaces Old Three (3) Coat System – Zinc Rich Primer, Epoxy, and Urethane

- Save 60% of total cost and time (savings may vary)

| Traditional Zinc coating | Rust Grip® Aluminium coating | |

|---|---|---|

| Installation | • Requires lengthy sandblasting | • Minimal surface preparation |

| Application | • Involves multiple coats Epoxy • 3 Coat Systems • 4 Coat Systems |

• Polyurethane moisture-cure metallic, that cures faster. The higher the humidity the faster the curing • Total application time maybe reduced by 75% |

| Moisture Prevention | • Limited protection from mould and mildew | • Stops water vapor transmission through electro-chemical freezing |

| Longevity | • Shorter lifetime endurance | • Penetrates deep into pores of surfaces |

| Corrosion | • Not effective at blocking long-term degradation | • Adds strength to weakened surfaces |

| Repair and Maintenance | • Requires continual repair or complete overhaul | • Reduced surface preparation and efficient application yields cost savings |

| Surface Preparation | • Sand Blasting • Sa 2.5, NACE2, SSPC10 |

• Cost is reduced due to high surface tolerance of Rust Grip® • SSPC1+SSPC2+SSPC3, St.2+St.3 • Grit/Garnet cost eliminated or reduced by up to 75% |

| Encapsulation | • Unable to encapsulate | • Encapsulation of Asbestos, Lead-based paint and Biohazards |

| Configuration | • Multi-component system with various mixing ratios |

• Self priming • Single-component system consists of only Rust Grip® |

| Performance | • Limited Performance • Cannot match Rust Grip®‘s Laboratory or field performance | Perfect Score: • ASTM B117 Salt Spray Fog Test: 15,000 hours = 30 years • ASTM D5894 Standard Practice for Cyclic Salt Fog/UV Exposure of Painted Metal; 10,000 hours • ASTM E1795 Standard Specification for Non-Reinforced Liquid Coating Encapsulation Products for Leaded Paint in Buildings |

Unique Encapsulation Coating

Rust Grip® is tested to encapsulate toxic elements such as existing lead-based paint, asbestos and other biohazard materials. Passing 15,000 hours (= 30 years) of ASTMB117 with the Top Score of 10 at only 150 microns dry (6 mils) and with scribe 500 hours, no blistering.

Rust Grip® instantly seals, strengthens and protects, while stopping rust and corrosion in its path!

Global Organisations using RUST GRIP®

- Halliburton – One of the world’s largest oil field service companies

- Eni SpA – Italian multinational oil and gas company

- Pemex Oil – Mexican state-owned petroleum company

- Saipem SpA – Italian multinational oilfield services company

- Chevron – American multinational energy corporation

- Saudi Aramco Oil – The Saudi Arabian Oil Company

- Gazprom Oil – Russian state-owned oil producer

- Petrobras – State-owned Brazilian multinational corporation in the petroleum industry

- Shell Global – Group of energy and petrochemical companies

- ExxonMobil – American multinational oil and gas corporation

- Rowan Companies, Inc. – leader in domestic and international oil drilling

- Drydocks World – Dry docks facility located on the Persian Gulf, Dubai, United Arab Emirates

- Ecopetrol – State owned Colombian petroleum company

- Mubarak Marine – Marine and offshore service organization based in Dubai

- Berkshire Hathaway Energy – Power and energy distribution companies

- Workstrings International – The only global provider of (high-specification) downhole rental tubulars and accessories for drilling

- United States Army

- Taiwan Navy

Among the 3 single-component zinc-free paint systems tested, the Rust Grip® showed the best performance. This product stood out for its adherence to the substrate St3, low corrosion advance from the incision and no corrosion points to the end of tests.

State-owned Brazilian petroleum multinational corporation

Rust Grip® is reviewed and approved by these organisations:

- USDA Product Safety Branch

- DNV (Det Norske Veritas)

- Louisiana Dept. of Transportation

- Georgia Dept. of Transportation

- IMO (International Marine Organisations)

- ABS (American Bureau of Shipping)

- US Coast Guard

- Transport South Australia

- Exova Laboratories

- Petrobras

- Tennessee Dept. of Transportation

- University of Kentucky

- FAA Building Restoration Specification

- Workstrings International

- United States Army Construction and Engineering Research Laboratory – Fort Bragg

- US Army Corps Engineers – Moisture Cured Urethane Testing various products

Lead based paint encapsulation at Fort Bragg, North Carolina

Products Rust Grip® and Enamo Grip®

Rust Grip® Encapsulates Lead-Based Paint, Asbestos and Corrosion

Numerous steel structures such as water tanks, bridges, aircraft hangars, antennas, ladders, poles, railings, catwalks, fire hydrants, fuel storage tanks, and metal buildings were constructed or installed with lead-based coatings. The removal of lead-based paint from steel structures is currently accomplished through a variety of methods, the most common being abrasive blasting.

Prior to recoating steel structures, abrasive blasting is required in order to remove the old lead-based paint and to provide adequate surface profile for bonding the new paint to the substrate. During abrasive blasting, a tight containment structure is required to prevent lead dust from contaminating air, soil or water. Inside such containment structures, increased worker protection is required due to high lead dust concentrations. The large, concentrated volume of waste generated by abrasive blasting is hazardous and requires additional stabilization treatment prior to disposal. RUST GRIP® eliminates sandblasting. Read More >

Rust Grip® v Hot Dip Galvanising

Marine Corps Air Ground Combat Center Twentynine Palms

The Marine Corps Air Ground Combat Center, also known as 29 Palms, is the largest United States Marine Corps base. It is owned by The Department of Defense which is America’s largest government agency. It is officially known as Twentynine Palms Base in southern San Bernardino County, California. Upon building new structures on the base, Rust Grip® and Enamo Grip® were chosen because it was a great option versus hot dip galvanising for several reasons:

- Replace the galvanising process which is toxic

- Hot Dip Galvanising can possibility distort steel over large spans

- Rust Grip® application accelerates the schedule of building construction

- Rust Grip® reduces the costs for buildings

- Rust Grip is a green product and innovative process

Military applications

Rust Grip® vs Surface Coating and Galvanized Metal

With solvent carriers that allow it to penetrate deep into the pores of surfaces, Rust Grip® outperforms typical surface coatings. Traditional coatings adhere to roughness on the surface layers and are susceptible to wearing over time. Oxidation and acid rain can enter and begin corrosion, even though the surface coating remains intact.

After it penetrates, Rust Grip® draws moisture from the atmosphere which reacts with the active ingredients of the base component. This results in a gassing effect of the molecules and expands them swelling into all the pores to block out air, gasses, and moisture and to encapsulate the surface. The surface cannot breathe, cannot get moisture, and cannot oxidize again.

When other corrosion coatings are applied to surfaces after a completed white metal blast, corrosion redevelops after only 6 months to 2 years under the coating film, causing bubbles on the surface from the corrosion off-gassing.

Galvanized metal and re-galvanized metal has been hot pressure treated with zinc oils. Galvanization doesn’t anchor itself inside the pores, but stays on the surface. Therefore, galvanized metal lacks the strength and durability of Rust Grip® and can start to re-corrode in as little as 2 years. In hot climates (as per US Government Reports), the galvanized metal will crack, peel and deteriorate quickly and over long spans it can also warp or buckle beams.

A surface coated with Rust Grip® is strong and resilient. It is a durable coating that offers long life in extreme conditions, outperforming galvanized surfaces. It’s designed to last over 20 years or more in the toughest environments without a topcoat (source).

Big step on replacing Galvanising to stop corrosion

Douglas Pearce, our colleague distributor in Canada was able to get Rust Grip® specified in place of using galvanising. This is a very big step for Rust Grip® to replace galvanising to stop corrosion. Download: Dalhousie University 2018-124 Addendum 1 Propane addendum

Rust Grip® Videos Around The World

Rust Grip® provides protection against conditions where the surface cannot be sandblasted or worked upon extensively. It is a replacement to 3 in 1 coating systems and challenging the standard practices as a much more robust solution so clients can focus on pivotal issues rather than worrying about their assets degradation.

15,000 hours (=30 Years) Salt Fog Test for Rust Grip®

SPI Coatings coated some plates with HPC on it at 12.5mm or 500 mils. This was over-coated with Rust Grip® to seal and prevent water and air from getting to the HPC.

They placed these plates inside a salt-spray cabinet for the ASTM B117 testing to see how well the Rust Grip® would protect the HPC from salt spray and UV cycles.

It has been 15,000 hours and they look like the first day placed inside the cabinet.

The HPC would be both protected and there’d be zero corrosion on any pipes underneath which could manage 500-550°C internal temperatures. This is a great solution to reduce any threat of corrosion under insulation that most companies have using fibreglass jackets etc. See the Report pdf

Rust Grip® on Fibreglass

You can use Rust Grip® on fibreglass if the surface has porosity. If no pores for the Rust Grip® to penetrate down into, then no way for it to anchor and lock down. You can ‘roughen’ up fibreglass to create pores for penetration.

Rust Grip® and Chemicals

Rust Grip® has been tested against 1,500 different chemicals and is only unsuitable for continuous immersion in ammonia and urea derivates.

Concrete Gas Encapsulation

Rust Grip® tested and patented to seal off biohazards by incapsulating the surface and sealing it down to to a permeability of 0.24 perms. Anything less than 1.0 cannot breathe air, moisture and most gases. With the issue of Radon gases for example, 3 coats should lock it down.

Mould and Mildew

Rust Grip® has the ability to protect against mould and mildew on surfaces that are prone to damage from prolonged exposure. Rust Grip® creates an unsurpassed protective surface, proven time and again through onsite evaluations and real-world applications.

You would need to treat the surface with either bleach or 10-15% hydrogen peroxide to kill the mould then topcoat with 100-150 micron DFT of Rust Grip®. Rust Grip® has a permeability of 0.24 perms. That means it has no porosity. In the ASTM E 1795 liquid encapsulation test there are about 20 tests needed to pass to be considered an encapsulation coating. That’s where the 0.24 perms comes from.

The ASTM E 1795 test verifies Rust Grip® ability to encapsulate lead based paint. If there is paint and is flaking you will need to scrap off the loose bits as Rust Grip® may not be able to compress it then encapsulate. The encapsulation is based on the paint that is adhering to the surface.

What’s the difference between Rust Grip® and a rust converter?

Rust Grip® works by penetrating through and rust, encapsulating it and preventing further expansion. Rust converters work by chemically changing the rust into a benign form which only lasts for a few months and must be overcoated (source).

What surfaces can Rust Grip® be applied to?

RUST GRIP® can be applied to aged or new steel or aluminium, concrete, wood, and rusty or corroded steel and aluminium.

What about new steel?

Mill scale must be removed from new metal. If sandblasting put half to one mill glass profile, if hand tooling, remove all mill scale and put Rust Grip at 100 microns DFT over profile.

Generally, most new steel has mill scale from the manufacturing process but if there’s no mill scale, then Rust Grip can be applied as is. I’d still consider abrading the surface. If the mill scale has been removed it doesent require it but and abrasion will make better adhesion.

What if there’s a Zinc coating that can’t be removed?

If a project or site cannot be blasted or you can’t pressure clean or treat the area. Firstly thoroughly clean the surface, remove all dust, flaking etc.

Zincs and Urethanes DON’T MIX so you need an Epoxy coating between them. You cannot use Rust Grip directly over any Zinc coating because it’s a urethane.

Our Epoxy corrosion coating Moist Metal Grip can be hard brushed into surface over the Zinc, around the bolts and everything at 100 microns.

This will not fix the current corrosion but it should stop future growth. Then you can apply Rust Grip (urethane) or Enamo Grip (epoxy) on top of the Moist Metal Grip (epoxy).

Moisit Metal Grip and Rust Grip

Heat always accelerates drying or curing. Moist Metal Grip normally takes 3 days to start a surface tightening in the curing process. Overcoat with Rust Grip after 2 days to lock the solvent resins together.

Testing Results

- Patented encapsulation of bio-hazardous materials

- Pull testing avg 1480 psi

- Exceptional adhesion: ASTM 5B rating

- Surface tensile strength: 6,780+ psi (478 bar)

- Withstands temperature after curing up to 163°C (325°F)

- Certified penetration of 18 layers of existing lead-based paint

- Endures 29,700 rub cycles without exposing existing lead-based paint

- Passed 15,000 hour salt spray test = 30 years

- Test “5” on Flame Spread (0-25 Class A)

- Meets EPA Guidelines

- Certified water barrier: ASTM D6904 and ASTM D7088 hydrostatic & wind driven rain

- Over 20+ years of successful use on oil rigs and pipe lines

Maritime Approvals

- DNV (Det Norske Veritas)

- Certified ABS (American Bureau of Shipping)

- Certified US Coast Guard – Certified

- Certified IMO (Internat’l Marine Organization)

- Full Rust Grip Certifications

Rust Grip® can protect and seal surfaces of steel, aluminium, concrete, wood, fibreglass, and other substrates. Rust Grip® will seal out moisture and air with a permanent membrane that stops penetration and deterioration, blocking chemical pollutants that cause corrosion and deterioration.

Building Lead Paint Approvals

Evaluation Report of Rust Grip Test Samples

Mississippi River Bridge, Baton Rouge, LA

Based on the field inspection and laboratory testing, Rust Grip is deemed a suitable coating for the protection of steel superstructures coated with lead based coating system in fair to poor condition as long as the substrate is prepared properly and the coating system is mixed and applied in strict accordance with manufacturers recommendations.

Rust Grip® Physical Data

- Solids: By weight 62.2% / By Volume 51.4%

- Coverage: 2.9m2 per litre (100 / 400 Sq. ft per gallon)

- Spread: 1-2 dry mil on metal will cover (400 sq.ft./gal.)

- Cure time at 70°F (21°C): 45 min – 2 hours to touch. Overcoat with Rust Grip® or other coatings immediately after surface is dry to the touch to achieve proper adhesion. Higher temperatures and humidity will shorten cure times, lower temperatures will slow curing. Must be overcoated within 2 hours or within 1 hour after reaching the dry-to-touch stage, or the surface must be lightly sanded to achieve good adhesion.

- Cures by reacting to moisture in the air

- Weight: 1.1 kg per 1 litre (9.18 lbs. per gallon)

- Surface Tensile Strength: 6,780+ psi

- Can withstand 163°C constant heat before the resins burn out

- VOC Level: 380 grams/litre (3.17 lbs/gal)

- USDA Approved: Lead and Chromate free (safe around foods)

- Impact Resistance: 200+ psi front/160+ psi back

- Shelf Life: up to 3 years (unopened) under appropriate storage conditions (see MSDS)

- Surface Application: All

- Note: Will accept other coatings such as ENAMO GRIP® and SUPER THERM®, but will not accept itself after 4 hours).

Decanting Tips

With regards to the tips for decanting a Rust Grip pail (5 US gallons/18.9 litres) to smaller tins. Purchase your tins in your required sizes.

Firstly stir slowly in the pail with a mechanical stirrer. Get all the aluminium particles up from the base of the pail. Slowly as it will reduce air/moisture being absorbed into the coating from the atmosphere.

If you have nitrogen handy and don’t want the Rust Grip to ‘cure’ in the tin if there’s lots of air, dispel it or keep the tins full of product.

Last tip is to use a funnel or have plastic around the rim of the tin. If Rust Grip is spilt and not cleaned the lid may be difficult to get off later. For quick solutions wedge a plastic bag between the tin and the lid.

Surface Preparation Tips

Unable to blast, hot permits or mechanical tools

With the surface preparation, if you’re under tight environmental controls, we’ve had applicators use citrus cleaners (ie Bunnings) for surface preparation. In the past for salts we’ve used Chlor Rid, however basic vinegar and water could achieve the result. Vinegar is mostly water, and because salt dissolves in water, the salt is being ‘washed’ out. There is no “chemical reaction” as such. We have also used methylated spirits in water to clean surfaces.

MUST BE COMPLETELY DRY BEFORE APPLICATION OF RUST GRIP.

Application

SPI Application instructions pdf

Can pressure clean with solvent wipe down, light commercial blast, or power hand tool to remove loose flake and debris before applying. Possible alternative to abatement of lead paints. Surfaces should be clean, dry and sound. Existing surface dirt, oil, tar, grease and film should be removed from surface by approved methods (TSP-Tri-Sodium Phosphate or equivalent) prior to application of Rust Grip®. MUST BE COMPLETELY DRY.

| Product | % solids by volume | Surface Profile Microns | Surface Profile Mils | Microns WFT / DFT | Spread m2/litre | Spread m2/gal | Spread ft2/gal |

|---|---|---|---|---|---|---|---|

| Rust Grip | 51.4 | 50 | 2 | 300 / 150 | 3.37 | 12.8 | 137.4 |

| 51.4 | 75 | 3 | 350 / 175 | 2.89 | 10.9 | 117.8 | |

| 51.4 | 100 | 4 | 400 / 200 | 2.53 | 9.6 | 103.1 |

NOTE: The number of coats necessary to achieve at least 100 microns / 4 mils DFT over the tallest peak of rust. If surface profile is 25-50 microns / 1-2 mils the minimum WFT application is 300 microns / 12 mils and 150 microns / 6 mils dry, which will allow to fill a surface profile and to have at least 100 microns / 4 mils of DFT over the top of tallest peak of rust.

Rust Grip® Temperature/Humidity Chart

Approximate Time to Overcoat Window

| Relative Humidity | 32°C | 21°C | 10°C |

|---|---|---|---|

| 90% | 1 hour | 1.5 hours | 2-3 hours |

| 80% | 1 hour | 1.5 hours | 2-3 hours |

| 60% | 1.5 hours | 1.5-2 hours | 3-4 hours |

| 40% | 1-2 hours | 2-4 hours | 6-8 hours |

| 30% | 2-3 hours | 3-6 hours | 10-14 hours |

| 20% | 6 hours | 8-10 hours | 12-16 hours |

| 10% | 12 hours | 12-18 hours | 18-24 hours |

These are rough estimates and are due to fact that coating in uncontrolled conditions results in many variables that can effect these times. Weather can often change significantly over the time periods. Download pdf

Times are estimates of how long it will take Rust Grip® to enter the overcoat window when the next coat may be applied. The definitive test for when Rust Grip® may be over coated remains the “touch” test when the coating may be touched with no colour transfer, and no damage with thumbnail.

New Steel

We normally suggest wipe down the steel surface with a citrus cleaner, dry, then abrade the surface with tough sand paper for metal or short hair wire brush. The objective is to abrade the surface, break it up so there’s a mechanical bind for Rust Grip. It’s not designed as a topcoat; it’s an encapsulation coating. It penetrates, swells with moisture in the air and then anchors in, making it tough and binding. Clean the surface before application.

Important

Stir product thoroughly before using. Avoid a vortex when stirring to draw in moisture. Rust Grip® can be applied by brush, roller or spray equipment. It should be applied evenly without buildup to 200-300 microns DFT.

Rust Grip® should be immediately cleaned after it is applied. There is no way to remove Rust Grip® when it has set. Brushes and rollers must be thrown away. Flush spray machine, hoses and gun with solvents to clean out. When breaking for lunch, seal off Rust Grip® container (tip: separate lid from tin with heavy duty plastic bag). Use caution when resealing the container, as any Rust Grip® on the seal track of the lid or container may cause the two surfaces to permanently seal.

Because Rust Grip® works rapidly, do not leave a container open to the air for longer than 4 hours, or Rust Grip® will draw in the ambient humidity and begin to cure. A brush or roller used to apply Rust Grip® cannot be cleaned.

SOLVENT: Clean-up or reduction, use MEK, Xylene or MIBK. If sprayed, keep solvent ready to clean equipment before breaks (lunch hour) or at conclusion of job. Run solvent through the machine and hoses and leave gun submerged in solvent pail. *CLEAN IMMEDIATELY OR WILL RUIN EQUIPMENT.

When storing Rust Grip® as it’s moisture cured use Nitrogen gas to expel oxygen in the tin to reduce chances of the coating from curing.

Moisture Cured Urethanes and Acrylic Paints

Rust Grip® is a moisture cured urethane and is not compatible with a water based acrylic latex (as per table 6.2 of AS/NZS2312). It is recommended in this situation, you have to do a test spot.

Reason: Rust Grip® is not a glue. It penetrates through the existing acrylic. If the acrylic is not high quality, the Rust Grip® can penetrate into it and when it tightens down, can lift the acrylic off the surface and peel off. Rust Grip® penetrates, so have to do the test to see if the acrylic can hold up to the strength of Rust Grip®.

Cautions and Warning

CAUTION: Wear gloves and protective clothing. Extremely tough to clean off skin. Wear eye protection and mask.

Do not take internally. Avoid contact with eyes. If solution does come in contact with eyes, flush immediately with water and contact a physician for medical attention. Avoid prolonged contact with skin or breathing of spray mist. KEEP OUT OF REACH OF CHILDREN. This is a flammable liquid. Keep away from flame or fire or other sources of ignition.

Practice standard safety precautions when working with Rust Grip®, including protective clothing. Rust Grip® will adhere to and cure on skin. Rust Grip® is USDA-approved, but it will wear on skin for several weeks before being sloughed off with normal skin renewal.

Rust Grip and Offgassing Bubbles (application)

In the application sheet it states: For temperatures 35C and above with less than 20% humidity: Rust Grip® will dry to touch but will not be completely finished gassing off. If you can move the coating with your fingers, it is not set hard enough to overcoat; if over-coated too soon or the surface is too hot, bubbles will be caught in the top coat. It is a result of the surface curing fast (direct sunlight or high ambient temps) and the solvents trying to get out of the coating causing bubbles. First coat needs to off gas first. 99% of the time it is just cosmetic and doesn’t effect performance.