Thermal Insulation for Lithium Battery Systems

Super Therm®: A Revolutionary Solution for Protecting Lithium Battery Systems in Shipping Containers

As the global push toward renewable energy and sustainable solutions accelerates, lithium battery systems have become integral to energy storage and electric vehicles. These systems are increasingly housed in shipping containers to enable modular, scalable, and transportable energy storage solutions. However, maintaining the stability and safety of lithium battery systems in such environments presents a unique challenge, especially when exposed to fluctuating temperatures and external heat loads.

Super Therm®, the leading multi-ceramic heat-blocking insulation coating, offers an unparalleled solution for safeguarding lithium battery systems in shipping containers, ensuring efficiency, longevity, and safety.

The Challenge: Heat Sensitivity of Lithium Batteries

Lithium batteries are highly sensitive to temperature fluctuations:

- Excessive Heat: High temperatures accelerate chemical reactions within batteries, potentially leading to thermal runaway—a chain reaction that can result in fires or explosions.

- Low Temperatures: While less hazardous, cold environments can reduce battery capacity and efficiency.

Shipping containers, often made of steel, are prone to extreme heat absorption and rapid internal temperature fluctuations, particularly when exposed to direct sunlight or adverse weather. These conditions can significantly impact the performance, lifespan, and safety of lithium battery systems.

Lithium-ion batteries vs Nickel-hydrogen Batteries Comparison

Nickel-hydrogen batteries and lithium-ion batteries are two advanced energy storage technologies with distinct differences in their design, performance, and applications. Nickel-hydrogen batteries rely on nickel oxide hydroxide as the positive electrode and hydrogen gas stored in a pressurised metal hydride as the negative electrode. Lithium-ion batteries, by contrast, use lithium compounds for the positive electrode and graphite for the negative electrode. This difference in chemistry gives each battery unique properties suited to specific applications.

Energy Density and Application Suitability

One of the most significant differences is in energy density. Lithium-ion batteries excel in this area, offering higher energy-to-weight ratios, which makes them ideal for applications like electric vehicles, portable electronics, and other scenarios where compact and lightweight power sources are essential. Nickel-hydrogen batteries, while reliable, have a lower energy density, which makes them more suitable for applications where durability and longevity outweigh size and weight considerations, such as in satellites or industrial energy storage systems.

Nickel-hydrogen batteries stand out for their exceptional lifespan and durability. They can last over 20 years and endure tens of thousands of charge and discharge cycles without significant degradation. These qualities make them ideal for mission-critical systems, such as aerospace applications and renewable energy storage. Lithium-ion batteries, on the other hand, typically last between 500 and 2,000 cycles before performance begins to degrade, requiring careful monitoring and management to maximise their lifespan.

Lifespan, Safety, and Environmental Impact

Safety is another area where nickel-hydrogen batteries excel. These batteries are highly stable, even in extreme environments, and are resistant to thermal runaway—a failure mode that can cause overheating or fires. Lithium-ion batteries, while generally safe, are more prone to thermal runaway and require additional safety measures, particularly in applications involving high energy loads or extreme temperatures.

Environmental impact is a growing consideration in choosing between these technologies. Nickel-hydrogen batteries align with cradle-to-cradle sustainability principles, as they are fully recyclable and their materials can often be repurposed. Lithium-ion batteries, while widely used, pose greater environmental challenges due to the intensive mining of lithium, cobalt, and other materials. Recycling lithium-ion batteries is less developed and more complex, which can contribute to waste and environmental degradation over time.

Cost is another factor that sets these two technologies apart. Nickel-hydrogen batteries are more expensive to produce due to their specialised materials and relatively small-scale manufacturing. However, their long lifespan and reliability can offset these upfront costs over time. Lithium-ion batteries benefit from mass production, making them more affordable per unit, which has driven their widespread adoption in consumer electronics and electric vehicles.

Nickel-hydrogen batteries prioritise longevity, safety, and sustainability, making them ideal for critical, high-reliability applications in aerospace, renewable energy, and industrial systems. Lithium-ion batteries, with their high energy density and cost efficiency, dominate in sectors where compact and lightweight designs are essential, such as consumer electronics and electric vehicles. The choice between these technologies depends on the specific requirements of the application, including energy needs, environmental considerations, and budget constraints.

Why Super Therm® is the Ideal Solution

Super Therm’s advanced multi-ceramic heat-blocking technology is a proven game-changer in thermal insulation. Here’s why it excels in protecting lithium battery systems housed in shipping containers:

Exceptional Heat Blocking Performance

Super Therm® blocks 96.1% of total solar heat, preventing external heat from penetrating the container. By minimising heat transfer, it ensures the interior environment remains stable, even under intense solar radiation. This superior performance has been verified through extensive testing and real-world applications globally.

Maintains a Stable Interior Environment

By reflecting and blocking heat rather than absorbing it, Super Therm® creates a thermally consistent environment, critical for the optimal functioning of lithium battery systems. Stable internal temperatures reduce strain on HVAC systems, improve energy efficiency, and help maintain peak battery performance.

Lightweight and Space-Saving Solution

Unlike bulky traditional insulation materials, Super Therm® is applied as a thin coating—just 0.25 mm thick when dry. This ensures no loss of valuable interior space in the container, allowing for maximum utilisation for battery systems and ancillary equipment.

Durability and Longevity

Super Therm® forms a tough, durable barrier that resists environmental degradation. It withstands harsh weather, UV exposure, and physical wear, providing long-term protection for battery systems in stationary or mobile applications.

Safety and Fire Resistance

Lithium batteries require a non-flammable, stable environment to prevent catastrophic failure. Super Therm® adds an extra layer of safety as it is non-flammable and contributes to the overall fire resistance of the shipping container.

Energy Savings

By reducing the need for active cooling systems to manage heat, Super Therm® contributes to significant energy savings. This aligns perfectly with sustainability goals, reducing the carbon footprint of energy storage systems.

Solar-Powered Air Conditioners

Solar-powered air conditioning systems provide active temperature control without relying on grid electricity. They are also perfect for off the grid systems. By using clean, renewable energy, these systems maintain precise temperature ranges within the container, critical for lithium battery safety and performance.

When paired with Super Therm:

- The air conditioners require less energy as the heat load is already minimised.

- Solar panels operate at peak efficiency since they, too, benefit from reduced thermal stress when Super Therm is applied to their surfaces.

Super Therm’s Role in Humidity Control

While primarily known for its thermal insulation properties, Super Therm indirectly aids in managing humidity by stabilizing interior temperatures:

- Reduced Temperature Fluctuations: By blocking 96.1% of solar heat, Super Therm® minimizes temperature swings inside the container. Stable temperatures reduce the likelihood of condensation, which is a primary driver of humidity buildup.

- Barrier Against Moisture Intrusion: Applied as a seamless coating, Super Therm® adds a protective layer to the container, helping to block moisture infiltration from rain, dew, or high external humidity.

- Complementary Performance: Super Therm® reduces the strain on HVAC systems, allowing them to focus more effectively on dehumidification tasks.

Easy Application and Maintenance

Super Therm® can be easily applied to both the interior and exterior of shipping containers. Its seamless coating ensures full coverage without gaps or thermal bridges, offering comprehensive protection. Additionally, its maintenance requirements are minimal, making it a cost-effective long-term solution.

Proven Applications in Energy and Industrial Sectors

Super Therm’s performance has been demonstrated in various demanding environments:

- Renewable Energy Facilities: Protecting battery storage units from heat gain and loss, ensuring efficient energy storage.

- Industrial Settings: Reducing energy consumption and improving thermal regulation in extreme conditions.

- Global Reach: From the Florida Energy Office to the Las Vegas Airport to Japan’s industrial sectors, Super Therm® has been trusted to deliver thermal insulation results.

Enhanced System Performance and ROI

By ensuring the stability of lithium battery systems, Super Therm®:

- Extends battery lifespan by reducing thermal stress.

- Enhances safety, minimizing risks associated with thermal runaway.

- Lowers operational costs by reducing HVAC energy consumption.

- Boosts the reliability and efficiency of energy storage systems, ensuring a faster return on investment.

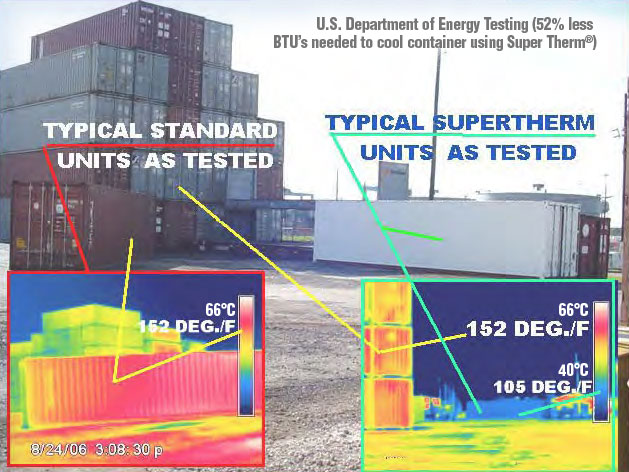

46-52% Energy reduction

Shipping Containers

- Conduction related energy loads were reduced approximately 46 to 52%

- Internal surface temperatures: 20°C (37°F) Cooler

- Outside Surface Reflectivity: 50% Higher

- Ultraviolet absorption rate: 92% Less

- Internal Moisture levels: 28.5% Dryer

On August 23rd & 24th, 2006 a test was conducted in LaPorte, Texas in accordance with the Florida Energy Conservation Assistance Programs Designation: ECAP-CUL-1-03 Method for Comparing Utility Loads in Structures and Buildings.

The objective of this analysis is to determine the impact of the “As Built Conditions and As Installed Components / Equipment” on the energy producing loads on occupied residential, commercial, government building and other structures. The focus of this procedure is to provide a comparison to known standards for all parties interested in using alternative and conventional conservation products and devices to displaced energy loads. This report reflects the performance characteristics of Super Therm®, as applied to the structures external surfaces, as a possible passive Energy Conservation Measure (ECM) to reduce internal Energy Loads and reduce the Heat Island Effects caused by exposed surfaces in urban areas.

Our data indicated that at the time of this survey the test specimen container inside surface conduction related energy loads were reduced approximately 46 to 52% by applying Super Therm® as an Energy Conservation Measure (ECM) to outside surfaces.

Average site weather conditions during the analysis period were as follows:

- High Temperature 36°C (97°F).

- Low Temperature 23°C (74°F)

- Average Wind Speed 2-4.7 knots (3 to 5.5 MPH)

- Average UV intensity 99 A+B

Outcomes:

- Inside container ambient temperature: 12°C (22°F) Cooler

- Thermal conductance to outside environment: 50% Less

- External surface temperature: 26°C (47°F) Cooler

- Internal surface temperatures: 20°C (37°F) Cooler

- Outside Surface Reflectivity: 50% Higher

- Ultraviolet absorption rate: 92% Less

- Internal Moisture levels: 28.5% Dryer

A Future-Proof Solution for Lithium Battery Protection

As the demand for modular lithium battery systems grows, so does the need for robust thermal management solutions. Super Therm® stands out as a cutting-edge technology that meets the challenge head-on, offering unmatched heat-blocking performance, durability, and safety. For industries reliant on lithium battery systems housed in shipping containers, Super Therm® represents not just a coating but a critical safeguard against heat-related risks.

By choosing Super Therm®, businesses can ensure their lithium battery systems remain stable, safe, and efficient, even in the harshest conditions—paving the way for a sustainable and energy-efficient future.