Oil and Gas for Insulation and Corrosion

Live-pipe insulation that eliminates CUI, slashes energy loss and cuts maintenance – the real life solution to a decades ongoing industry issue.

In oil and gas, heat loss and corrosion under insulation (CUI) are not theoretical problems. They shut units down, blow out maintenance budgets and quietly erode asset integrity year after year. This is particularly bad for below ground insulation pipes and corrosion under jacket insulation.

HPC® Coating (Hot Pipe Coating) is a multi-ceramic, high-temperature insulation coating system designed to be applied directly to operating equipment – pipes, vessels, tanks, exchangers and buried lines – from ambient up to 650°C.

Unlike wraps and cladding that rely on air gaps and get destroyed by moisture, HPC® Coating builds a continuous, closed, ceramic insulation layer right on the steel. It holds the heat where you want it, removes the CUI risk and can be applied without shutdowns on above ground pipes and reduces shutdowns below ground.

HPC® Coating is already delivering proven energy savings, EPA-recognised performance and below-grade solutions for major operators – and why it belongs on every serious oil and gas decarbonisation and reliability roadmap.

HPC Coatings clients

Here’s a small range of clients that have transformed their energy, CUI and maintenance with HPC Coatings. Due to confidentiality of some clients, project details and images aren’t available.

- BP Oil – Completed a platform in the Gulf of Mexico with HPC to control the heat on the pipes and boiler with RUST GRIP over to strengthen and a final coat of Enamo Grip to offer additional water protection and flexibility in case of abuse. Multi purpose: Insulation of the heat, Corrosion control (CUI) and water proofing

- Northern Natural Gas: Underground pipes

- FirstGas NZ: Above ground pipes for heat exchanger

- Beach Energy: Heater unit

- Pemex Oil: Offshore platforms, compressors, pipes and lines

- Saudi Aramco Oil – in the petrochemical plants and pipelines

- Ecopetrol Oil – (Colombia, S.A.) – Pipelines and tanks

- Gazprom Oil – (Russia) – Hot Pipes in the petrochemical plants in Siberia

- Kazakhstan Oil – for petrochemical plants

- LuOil (Division of Gazprom) – pipelines

- Belgium Oil divisions – hot pipes

- China National Oil Group – Pipelines and tanks

- Hospitals and commercial buildings for steam pipes

- Naval – ships and Coast Guard Approved for steam pipes.

The real problem: energy loss + CUI on hot and buried assets

Traditional insulation in oil and gas is built around jackets, lagging and fibrous batts. It works on paper and fails in the field which says a lot about lab testing:

- Moisture ingress through joints, damage and penetrations leads to saturated insulation, loss of thermal performance and aggressive CUI.

- Inspection is painful. You have to strip cladding to see the steel, then rebuild it. That drives deferrals and “run to failure”.

- Below-grade and splash zones are worst. Soil moisture, movement and chemistry destroy wraps and jackets quickly, accelerating corrosion.

- Complex geometry – elbows, valves, supports, nozzles – are hard to wrap properly. Gaps and voids become water traps.

The result is a familiar pattern:

- Higher fuel and steam consumption to hit process temperatures.

- Unplanned downtime for CUI repairs.

- Large volumes of contaminated insulation sent to landfill during every outage.

- Ongoing safety risk where surfaces are too hot for personnel.

HPC® Coating was designed from the ground up to remove those weaknesses, not patch around them.

What is HPC® Coating?

HPC® Coating is a family of water-borne, ceramic insulation coatings developed by Superior Products International II, Inc. as a true thermal barrier for high-temperature equipment:

- HPC® Standard – Ambient up to 204°C (Australian HPC SDS pdf)

- HPC®-INT – 204°C up to 426°C

- HPC®-HT – 426°C up to 650°C

All three use low-density ceramic loads in advanced resin systems to build a non-conductive, thick-film insulation layer directly on steel.

Key technical characteristics from published product data and distributors:

- Temperature capability: up to 650 °C with HPC-HT on live hot surfaces

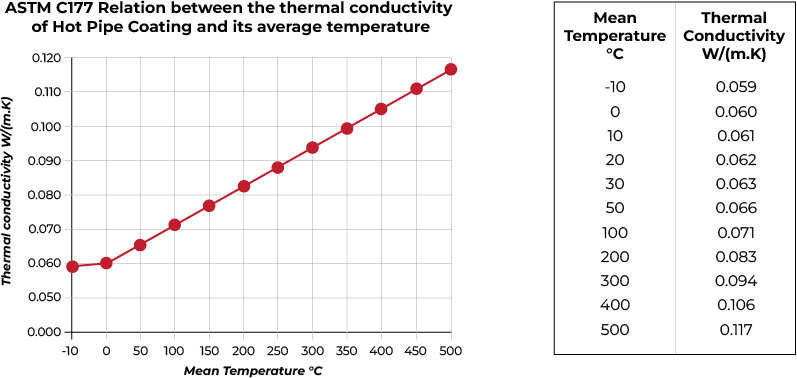

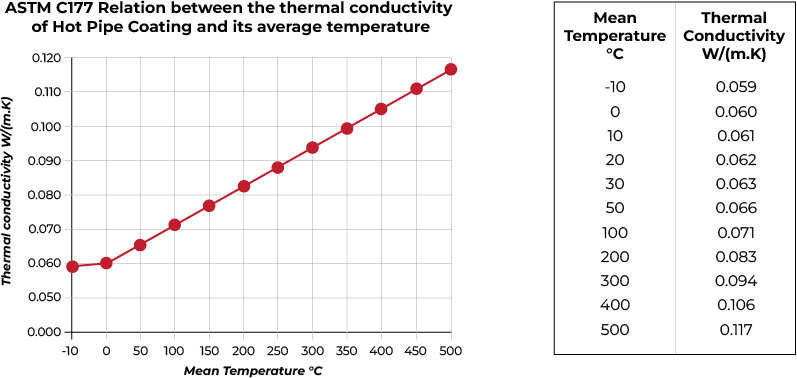

- Thermal conductivity: around 0.06 W/m·K (ASTM C177) reported for HPC Hot Pipe Coating. Source

- Volume solids: ~72 %, allowing substantial dry film build per coat

- Water-based, low VOC, non-flammable application for HPC / HPC-INT

- NASA-derived ceramics: the lightweight, low-density ceramics were originally developed with NASA in the early 1990s.

Instead of relying on trapped air in a jacket, HPC® Coating ceramic matrix catches and holds heat at the steel surface, reducing conductive and convective losses along the whole line or vessel. Field tests have shown that, with no change in firing rate, internal temperatures and pressure can rise because less energy is being lost out through the shell.

For operators, that translates directly to:

- Lower fuel and steam demand for the same duty, or

- Higher throughput and more stable process temperatures at current fuel rates.

ROI Case Study

ROI (Return on Investment) calculations for 37mm thick HPC application to a 16″ OD steam

pipe, 350m length and in energy savings and actual amount of gas (CH4) saved and sold on

the World Market. Data from the spread sheet:

| Total transmitted thermal power with no insulation Q total = 2,389.9 KW |

| Total transmitted thermal power with HPC insulation Q total HPC = 394.1 KW |

| The difference in transmitted power after HPC insulation Q saved = 1,995.8 KW |

Data from engineering tool box:

| 1KW = 3,412 BTU/hr |

The difference in transmitted thermal power after HPC insulation in BTU/hr:

Qsaved = 1,995.8 KW x 3,412 BTU/hr = 6,809,700 BTU/hr

BTU saved in 24 hours, 365 days (1 year) operation:

6,809,700 BTU/hr x 24 hr x 365 days = 59,652,972,000 BTU saved in one year by using 37 mm of HPC

How many m3 of Natural Gas (CH4) represent this number?

1m3 CH4 gas contains 33,549 BTU (1m3 = 35.315ft3; 950BTU/ft3 X 35.315ft3 = 33,549BTU) Now, this output in BTU based on the 100% efficiency of the heating system and HHC (High Heat Content in the CH4). In reality the amount of heat actually used for heating will be at least 20% lower 33,549 BTU – 6,710 BTU = 26,839 BTU, and the m3 of gas saved is 59,652,972,000 BTU/26,839 BTU/m3 = 2,222,622 m3 of gas saved 2,222,622 m3 = 78,491,896 ft3

Price of Natural Gas sold on the world market vary, but lets say the price for 1,000 ft3 (contains

1,000,000 BTU in heat energy) is ~ US $5.00

Total dollar amount saved in one year by using 37 mm of HPC:

78,491,896 ft3 / 1,000 ft3 x $5.00 = $ 392,459

Depending on the cost of the project, ROI could be as fast as 1.5 years or less

Lets say the project cost is $600,000

ROI = $600,000 / $392,459 = 1.5 years

Below-grade and buried pipelines: a new insulative coating system

Below-grade hot lines are a chronic headache: almost impossible to monitor, expensive to excavate and prone to aggressive CUI once traditional insulation and coatings degrade.

SPI Coatings in the US works with the largest interstate pipeline operator in the United States, developed a novel below-grade insulative coating system built around HPC® Coating:

- Fusion-bonded epoxy (FBE) as the primary corrosion barrier on the pipe

- HPC® Coating applied over the FBE as the insulating layer

- Proprietary polyester mesh wrapped into the HPC while wet to provide structural reinforcement

- Marine-grade epoxy topcoat as a tough, fully sealed outer shell against soil moisture and movement.

Project details

- Glycol (water) Pipes

- Winter Freeze Protection

- 182 metres

- 100mm pipe diametre

- 7.6mm dry film depth

- Recycled glycol to heat up the pipe for accelerated curing

This system gives buried lines:

- A continuous, fully bonded insulation layer with no voids or air pockets

- A high-performance corrosion barrier system with multiple layers of defence

- Stable thermal performance because there is no fibrous insulation to soak up water or collapse

- Protection for both above-grade transitions and fully buried segments, using the same technology.

For oil and gas operators, that means you can design buried hot lines for performance and longevity, not just hope the wrap and jacket survive another cycle in wet, corrosive soil. See the project!

Georgia-Pacific: EPA ENERGY STAR Award and 49% heat-loss reduction

The most visible proof of HPC’s performance comes from Georgia-Pacific’s Naheola paper mill digester tank in Alabama.

Georgia-Pacific and Flint Hills Resources trialled a range of insulation options, then fully insulated a large digester with HPC® Coating. The result was:

- 49% reduction in heat loss from the vessel

- Estimated US$332,000 in annual energy savings on that single unit

- Improved cooking temperature stability and process quality.

- No progression of existing corrosion under the coating during the monitoring period.

This project won Georgia-Pacific a US EPA ENERGY STAR Energy Saving Award for New Technology in 2023, specifically recognising the performance of HPC® Coating as a breakthrough insulation solution.

Independent Georgia-Pacific engineering documentation reports a $332,000 in energy costs savings annually equivalent to 13–18-month ROI on this application, with the technology capable of saving hundreds of thousands of dollars on one unit in one year and millions across the company.

For oil and gas, the message is simple: HPC delivers measurable, independently recognised energy savings at industrial scale, not just in a lab coupon.

HPC® in oil & gas service: live pipes, refineries and offshore

HPC® Coating is already working in the environments oil and gas cares about most.

LPG refinery and Gazprom hot pipes

SPI Coatings reports multiple refinery projects where 30 mm of HPC® Coating on 550°C steam pipes at an LPG refinery in Europe brought surface temperatures down below personnel-safe levels, with video-verified performance.

In a separate field comparison for Gazprom (Russia’s largest LPG energy supplier to Europe), HPC® Coating was applied directly over a 470 °C live pipe:

HPC® Coating reduced the surface temperature to around 26°C, achieving a ~444 °C drop at ~31.7 mm thickness – about 5.3 times more effective per mil than a competing “high-performance” coating.

That trial was done while the line was operating, with no shutdown and no hot work permit.

Pemex – Gulf of Mexico pipelines

HPC® Coating has been applied to Pemex oil pipelines in the Gulf of Mexico. Published material notes that since installation in 2014, there have been zero performance issues, no CUI and improved energy savings reported on these lines.

For offshore and marine-exposed assets, that combination of CUI resistance and long-term thermal stability is critical.

Hyundai Oil – heat exchanger and heater coatings

A documented field test at Hyundai Oil Bank’s Daesan refinery applied HPC on heat exchanger covers and heater walls:

- On one exchanger cover:

- Surface temperature before coating: ~202 °C

- After HPC (12–15 mm), Super Therm® topcoat and Enamo Grip finish: ~65 °C – a 68 % reduction in surface temperature.

- On a heater exterior wall, a similar step-up in surface temperature performance was recorded with a thin HSC/HPC system.

This is classic oil and gas duty: high-temperature carbon steel, aggressive atmospheres, energy-intensive equipment. HPC® Coating delivers insulation and personnel protection without wraps or shutdowns. See the project

Sulphuric acid plant – hot acids, harsh chemistry

In Korea, HPC® Coating was used to replace 15–25 cm of rockwool plus 0.6 mm metal jacket on sulphuric acid pipelines, valves and storage tanks where temperatures were in the 320–470 °C range.

The HPC® Coating system reduced surface temperatures dramatically, while removing the long-term CUI risk from saturated rockwool in a highly corrosive environment. See the project

Cold pipe insulation and sweating control

HPC® Coating isn’t limited to hot lines. SPI’s field testing includes cold applications where HPC® Coating (over Rust Grip, with Super Therm® and Enamo Grip topcoats) prevented sweating on a 7°C pipe at 34–38°C ambient. Moisture only appeared at about −1 °C with no dripping – effectively stopping condensation and corrosion on cold service lines.

That’s directly relevant to gas processing, LNG, chilled water and refrigeration piping.

How HPC® Coating delivers real energy and OPEX savings

HPC’s performance advantage isn’t marketing spin – it comes from physics and field data.

1. True insulation, not just “thick white paint”

Many so-called “insulating” or “cool” coatings are reflective paints or thin films below 1 mm. They may lower surface temperature in the sun but do not provide meaningful insulation at 150–600 °C.

HPC® Coating is different:

- It is designed to be built up in multi-millimetre thicknesses (e.g. 6–30mm) to deliver real thermal resistance

- Independent product data lists a conduction value around 0.06 W/m·K, putting it squarely in insulation territory rather than decorative coating

- Field comparison work on steam pipes shows fuel savings better than 35 % versus rockwool/fibreglass wraps in high-temperature service.

2. Full coverage on every surface

Wraps and cladding struggle around supports, valves, flanges and complex geometries. HPC is spray-applied, so you can:

- Insulate elbows, nozzles, tie-ins, shoes and “awkward bits” with the same coverage as straight runs

- Eliminate voids and gaps that become water traps and hot spots

- Achieve 100 % surface coverage on process equipment, improving both thermal and corrosion performance.

3. Stable performance over time

Fibrous insulation collapses, absorbs water and degrades. HPC’s ceramic matrix:

- Maintains its density and structure over the life of the coating

- Does not wick or hold water like mineral wool

- Shows no significant drop-off in performance in long-term field cases such as Pemex’s pipelines and the Georgia-Pacific digester.

That means your energy savings are not just good in year one – they remain predictable throughout the asset’s service life.

Killing CUI instead of managing it

CUI is driven by the combination of trapped moisture, oxygen and steel. Traditional insulated systems give that chemistry the perfect home: wet fibrous insulation pressed against hidden metal.

HPC attacks that dynamic from several angles:

- Monolithic barrier: HPC forms a continuous, bonded layer directly on the steel, with no cavities for water to hide

- Water-resistant system: in the below-grade configuration, the combination of FBE, HPC, mesh and marine epoxy keeps soil moisture out of contact with the pipe wall

- No jackets to trap water: inspection on above-grade assets is simple – you can see the coating. Touch-up and repair are local and straightforward

- Corrosion under insulation: Georgia-Pacific’s test work reported no worsening of underlying corrosion under the HPC system, even where some corrosion existed before coating.

That doesn’t just lower risk; it also translates to less unplanned outage, fewer emergency repairs and lower lifecycle cost than repeated re-wrapping and jacketing.

Typical oil and gas applications for HPC® Coating

HPC® Coating is already used across a wide range of energy and heavy industrial applications, including:

- Refinery and petrochemical:

- Steam and condensate lines

- Heaters, furnaces and convection sections

- Heat exchanger shells and covers

- Distillation columns, reactors and reboilers

- Gas processing and LNG / LPG:

- Hot gas lines and transmission pipelines

- Regeneration heaters, amine and sulphur service

- LPG steam lines and manifolds

- Cold lines where sweating and icing must be controlled

- Pipelines and terminals:

- Above-grade lines in pipe racks

- Below-grade and road-crossing segments using the FBE + HPC + mesh + epoxy system

- Pump station and manifold pipework

- Offshore and marine:

- Hot lines and equipment exposed to salt spray and marine atmospheres

- Deck piping where space and access make wraps impractical

- Storage tanks and vessels:

- Digester and reactor shells (Georgia-Pacific)

- Sulphuric acid and chemical tanks in harsh process environments

Across these applications, operators are targeting:

- Energy reduction and emissions cuts

- Elimination of CUI risk

- Improved personnel protection

- Reduced maintenance and landfill

HPC is one of the few technologies on the market with decades of field history, third-party recognition and hard numbers to back those goals.

HPC Coating Thermal Performance & Testing

What is the thermal performance of HPC® Coating?

HPC® Coating is tested under:

- ASTM C177 for thermal conductivity

Conduction Testing via ASTM C-177 Method:

Thermal conductivity over three tests: 0.560 BTU

To find the Lambda Value or K (0.560 X 0.144 = 0.0806 k value – Average 600 mils (14mm)

Convert k 0.0806 X 0.5778 (Heat Conversion Handbook Pg. 506) to K for sq.m = 0.0466.

Whereas R = 1/K = 21.46 - ASTM Flash Method (E 1289 and E 1461-92)

Conduction Testing via the ASTM FLASH METHOD (E 1269 and E 1461-92)

K value average is 0.1083

0.1083 X 0.5778 = 0.063K for sq.m

R-1/K – 15.87

Average 38 mils (.90 mm)

A detailed thermal analysis (energy efficiency vs. DFT) can be provided upon request or see this report.

Does HPC® Coating meet Australian Standards?

HPC® Coating is part of advancements in materials science, addressing modern insulation challenges. While these coatings represent new technology, they are being tested and specified by leading Australian companies such as Viva Energy and FirstGas NZ but not yet regulated as there’s no standards set for these coatings.

HPC® Coating vs conventional wrap insulation

Published comparisons and field tests make the trade-offs clear:

- Direct spray application to live hot surfaces

- No shutdown required in most cases

- Insulates complex geometries with full coverage

- Eliminates jackets and fibrous wraps – no CUI nests

- Stable thermal performance, no collapse or saturation

- Easy inspection – the insulation is the outer surface

- Long service life with simple recoating where needed

- Significantly reduced labour, downtime and disposal costs

- Demonstrated 35 %+ fuel savings and EPA-recognised energy performance

Traditional wraps (rockwool / fibreglass + cladding)

- Typically requires shutdown and scaffolding to install

- Vulnerable to mechanical damage and water ingress

- Difficult to install correctly on valves, supports and nozzles

- High risk of CUI in wet or marine environments

- Performance degrades as insulation compresses or saturates

- Inspection is intrusive and costly – cladding removal/rebuild

- Regular replacement required, driving landfill and labour costs

When you price a system over a 10–20-year life – including fuel, maintenance and CUI repairs – HPC is not a “premium coating”. It’s a lower total-cost insulation system.

HPC Coating repair procedure

- Cutaway the damaged coating

- Apply HPC coating to the area after removed and clean

- Apply more HPC Coating until thickness is reached

- When HPC coating is totally dry and less than 5% moisture apply RUST GRIP

- After RUST GRIP is dry to touch with no colour transfer, apply top coat as required

Working as a system with our other advanced coatings

HPC® Coating is part of a wider family of advanced coatings from SPI Coatings that can be combined for full-asset protection:

- Rust Grip® – surface-tolerant encapsulating corrosion coating for highly corroded steel, often used as a primer under HPC® Coating in severe C5 and marine environments.

- Moist Metal Grip – epoxy for wet or immersed surfaces such as below-grade and marine exposure.

- Enamo Grip – durable polyurethane topcoat for UV and chemical resistance over HPC® Coating.

- Super Therm® – multi-ceramic solar heat-block insulation coating that can be used externally on tanks, roofs and pipe racks to stop solar load while HPC® Coating handles process heat on hot surfaces.

Together, these systems let oil and gas operators future-proof assets against both heat and corrosion, above and below ground.

A proven insulation technology for serious operators

If you want incremental change, you can keep patching jackets and swapping out rockwool.

If you want structural change in energy performance, asset life and CUI risk, you need to move the insulation strategy closer to the steel – and make it stay there.

HPC® Coating offers:

- EPA-recognised, independently documented energy savings (Georgia-Pacific – 49 % heat-loss reduction and US$332k/year on one digester).

- Proven high-temperature performance up to 650 °C on live lines in refineries, gas plants and chemical facilities globally.

- Below-grade systems that finally give buried hot lines a credible insulation and corrosion solution.

- Long-term CUI control, including offshore and marine pipelines such as Pemex’s Gulf of Mexico assets.

- Reduced maintenance and landfill, with easy inspection and spot repair instead of constant tearing out and replacing wet insulation.

For oil and gas operators under pressure to decarbonise, improve safety and extend asset life, HPC® Coating is not an experiment. It’s a proven technology with real-world numbers and global references behind it.

References

Wayne Ferguson (LinkedIn) – Advanced Ceramic Coatings for Long-Term Energy Savings – Australia’s Opportunity (discussion of HPC)

https://www.linkedin.com/pulse/advanced-ceramic-coatings-long-term-energy-australias-wayne-ferguson-solqc LinkedIn

SPI Coatings – HPC® Coating: The Giant Leap in Advanced Insulation Performance

https://spicoatings.com/coating-products/hpc-coating/ SPI Coatings

SPI Coatings – HPC® Coating Product Line / EPA Award Excerpts (PDF)

https://spicoatings.com/wp-content/uploads/2024/04/B-HPC-COATING-PRODUCT-LINE-V2-03-2024-SPI-COATINGS.pdf SPI Coatings

Georgia-Pacific – EPA ENERGY STAR & SmartWay Recognitions for Sustainability Work

https://news.gp.com/2023/11/georgia-pacific-receives-epa-energy-star-and-smartway-recognitions-for-sustainability-work Georgia-Pacific News

SPI Coatings – Revolutionary Energy-Saving Game-Changer: Georgia-Pacific’s HPC® EPA ENERGY STAR Win

https://spicoatings.com/revolutionary-energy-saving-game-changer-georgia-pacifics-hpc-epa-energy-star-win/ SPI Coatings

NEOtech Coatings – Groundbreaking Energy Efficiency: Georgia-Pacific’s HPC® Coating Wins EPA ENERGY STAR Award

https://neotechcoatings.com/projects/groundbreaking-energy-efficiency-georgia-pacifics-hpc-coating-wins-epa-energy-star-award/ NEOtech Coatings

NEOtech Coatings – HPC® Coating

https://neotechcoatings.com/coating-products/hpc-coating/ NEOtech Coatings

NEOtech Coatings – Novel Below Grade Insulative Coating System – Underground Pipe Insulation

https://neotechcoatings.com/coating-products/hpc-coating/underground-pipe-insulation/ NEOtech Coatings

NEOtech Coatings – HPC® Coating FAQ

https://neotechcoatings.com/coating-products/hpc-coating/hpc-coating-faq/ NEOtech Coatings+1

Volta Coatings – Hot Pipe Coating™ Product Page

https://www.voltacoatings.com/product/hot-pipe-coating-tm Volta Coatings

SPI Coatings – Hyundai Oil – Heat Exchanger Cover Insulation Coating (PDF)

https://spicoatings.com/wp-content/uploads/2022/11/HPC-coatings-on-heaters-at-Hyundai-Oil.pdf SPI Coatings

SPI Coatings – HPC Application on Sulfuric Acid Tank and Valves in Korea (PDF)

https://spicoatings.com/wp-content/uploads/2022/11/HPC-on-tanks-and-valves.pdf SPI Coatings

Gruenbichler – HPC® Coating – High Performance Insulation Coating

https://gruenbichler.eu/en/special-coatings/thermal-insulation-coatings-from-hpc-coating/ Gruenbichler