Bulk Insulation: The History, Science and Future in a Hotter World

The Insulation needs Insulation Beyond the Status Quo

For decades, bulk insulation like fibreglass batts, rockwool, and polystyrene boards has dominated building standards worldwide. But as temperatures rise and energy costs spike, the conversation around how we insulate our buildings is shifting—and for good reason.

It’s why we call Super Therm® the insulation for your insulation. It doesn’t just delay heat—it blocks it. We don’t live in a lab. We live in a climate that’s changing faster than the insulation industry wants to admit. R-values are useful—but limited. Bulk insulation has a place—but is no longer enough. If you want to reduce energy, protect buildings, and stay cool in the 21st century, it’s time to go beyond the batt.

This article breaks down the history, advantages, and deep flaws of bulk insulation, especially in Australia’s harsh climate. It explores the weaknesses of R-values, the impact of poor installation, moisture problems, and why compressing insulation kills its performance. Finally, we compare conventional bulk materials with Super Therm®, a next-generation insulation coating that blocks solar heat before it enters the building.

The History of Bulk Insulation

Bulk insulation gained popularity in the mid-20th century with the rise of suburban housing and growing energy awareness. Initially used in cold climates to prevent heat loss, fibreglass batts and expanded polystyrene (EPS) were inexpensive, easy to mass-produce, and seemed effective—under steady-state lab conditions.

However, these products were never designed to perform under the dynamic, solar-radiation-loaded conditions typical of hot Australian summers.

For over 40 years, governments, the building, engineering and architectural industries worldwide generally have accepted the R-value for all things related to insulation, whether that be for fibreglass batt insulation or sisalation/sarking (radiant barriers in USA). The R-value is simply a time-based formula for resistance or conduction (absorption) of thermal heat transfer that essentially shows how fast heat is moving through the insulation. There are 2 types of ‘R value’. ‘Material R value’ & ‘System R value’ (sometimes called Total, stand alone or In Situ R value) (Higgins Insulation Builders Services, 2019).

R-value, which measures resistance speed of heat to transfer through insulation is the most popular building metric. There are two test methods that are important to measuring R-value. The first, ASTM C518, is relevant to single materials. In this test, a sample of the material is placed inside a heat flow meter apparatus, between a cold plate and a hot plate. Heat flows from the hot plate to the cold plate through the insulation as the testing device measures how much heat is flowing (Roberts, 2016).

In order to understand why Australia has an unwavering attachment to fibreglass bulk insulation we need to understand its history and origins. With no other options back in the day, the Federal Trade Commission (USA) promulgated the R-value Rule in 1979 to “address the failure of the home insulation marketplace to provide essential pre-purchase information to consumers, primarily an insulation product’s “R-value.” (Federal Trade Commission, 2018, p. 1). However if you ask many people what the R-value means they don’t understand beyond the term ‘resistance’.

Owens Corning is the world’s largest manufacturer of fibreglass insulation based in the USA with global manufacturing facilities and the creator of Pink Batts®. The company develops and produces insulation, roofing, fiberglass composites and related materials and products. It turned over $7.2 billion globally in 2019 and employs 19,000 people (Owens Corning, n.d.).

Driven by Harold Boeschenstein, aka ‘Mr Fibreglas’, by 1935, Owens Corning identified the potential growth and market size of the fiberglass building insulation and collaborated with Corning Glass in its development where in 1936 they applied for the trademark use of FIBREGLAS (with one S) (Tyrel Linkhorn & The Blade, 2013). By 1938 Owens Corning’s sales totaled $2.5 million and it employed 632 people. In 1939, Owens Corning produced a marketing booklet for the World’s Fair in Flushing Meadows, New York (Bob Catania, n.d.) showing how fiberglass insulation can be used in every corner of industry thereby entrenching the marketing of fibreglass insulation into the world’s psyche.

By 1946 Owens Corning sales were approximately $32 million and in 1947 The US Federal Government initiated an antitrust lawsuit (Owens Corning, 2017, pg 11) against Owens Corning, alleging an unlawful monopoly of the fiberglass industry. Owens Corning stated in August 1958 they set up Australian Fibre Glass Pty Ltd (ACN 000 044 306) with 40% ownership (Owens Corning, 2017, pg 15), however ASIC records show the company was set up in 1939 and deregistered in 2020. This shows the origins of Owens Corning in Australia before World War II.

Introduced in 1956, the bright pink color of fibreglass became such a powerful marketing tool that the company trademarked it in 1985. Fans watching the Superbowl in 1979 saw a commercial featuring a transparent “glass house” that showed “all the places insulation can save money.” The house was just a small plastic model, but the message was timely for a country still suffering through the energy crisis of the 1970s. “Put your house in the pink,” the announcer declared. “Get Owens-Corning Fiberglas insulation now; it’s cheaper than oil.” (Boyd, 2014). Coincidently it was at this time in 1979 that the FTC promulgated the R-value Rule which enforced fibreglass insulation regulations with R values of which Owens Corning’s fibreglass insulation was the only tested product.

With some very smart marketing by Owens Corning, in 1980 they used United Artists’ cartoon character the “Pink Panther” to help promote sales of pink Fiberglass insulation. Ogilvy and Mather from New York suggested the idea; to the point now where society still references the trademark as ‘pink batts’ (Marlene Harris-Taylor & The Blade, 2013) and by 1989 Owens Corning had sales of $3 billion employing 18,300 people around the world. Within a decade of adopting the furry mascot, company surveys showed that shoppers preferred Owens Corning’s PINK insulation by a ratio of five to one over the closest competition. By the end of the 1990s the edge grew to sevenfold. The value and size of a company of Owens Corning has significant influence and control globally at all levels of the insulation industry and Government (Image: Owens Corning, 2018).

The growth and domination of the fibreglass insulation industry globally since 1939, led by Owens Corning, is unquestioned and entrenched including here in the culture of Australia. Owens Corning have been outstanding global leaders in the bulk insulation industry and energy efficiency yet the development of advanced insulation technology and serious changes in our environment are proving to resolve new solutions to challenges that bulk insulation can no longer manage alone.

Inside the roof of a house can reach up to 80-90°C on a 40°C day with nothing protecting the building’s envelope to keep the solar heat out.

Original R-value testing 1977?

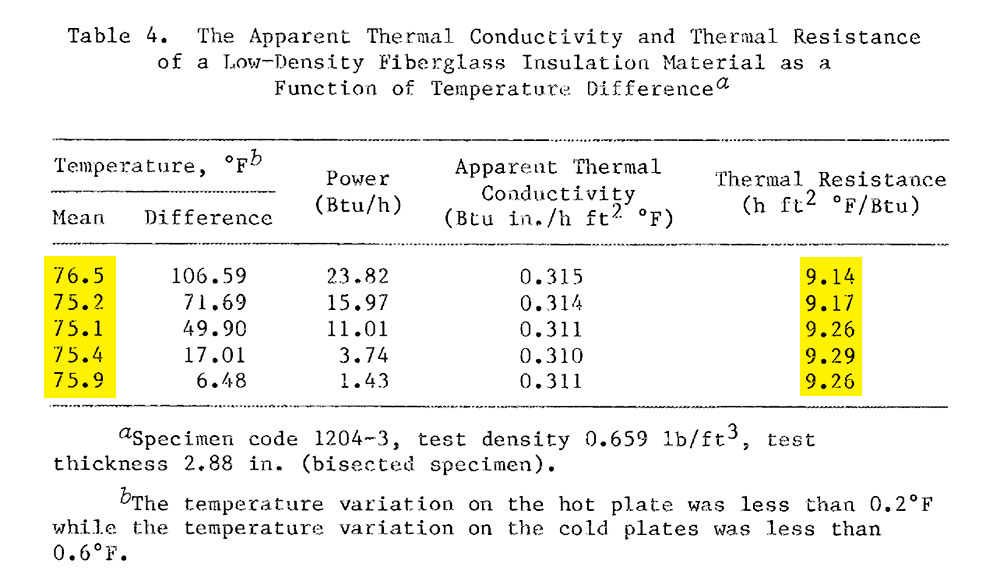

Bulk insulation has never been field tested in a variety of environments…because it can’t be. The original testing has been lab based in 1977 in the USA (Tye, Desjarlais, Yarbrough, & McElroy, 1980) with bisected specimens and it assumes every environment is 23.8°C (75°F) which is still the same test today. Essentially at 75°F air molecules have minimal vibration or activity. This ASTM C177 Test is used for fibreglass insulation to create the R-value that was developed by Owens Corning (Owens Corning, n.d.).

We know on extreme heat days temperatures reach in excess of 40°C+ and once bulk insulation is loaded with heat it is no longer effective. Inside the roof of a house can reach up to 80-90°C on a 40°C day with nothing protecting the building’s envelope to keep the solar heat out. Insulation rated for 23°C on a 40°C day will never keep up but it’s also storing heat that’s released at night into the house and the environment contributing to the UHI effect.

Fibreglass BTU testing 1977

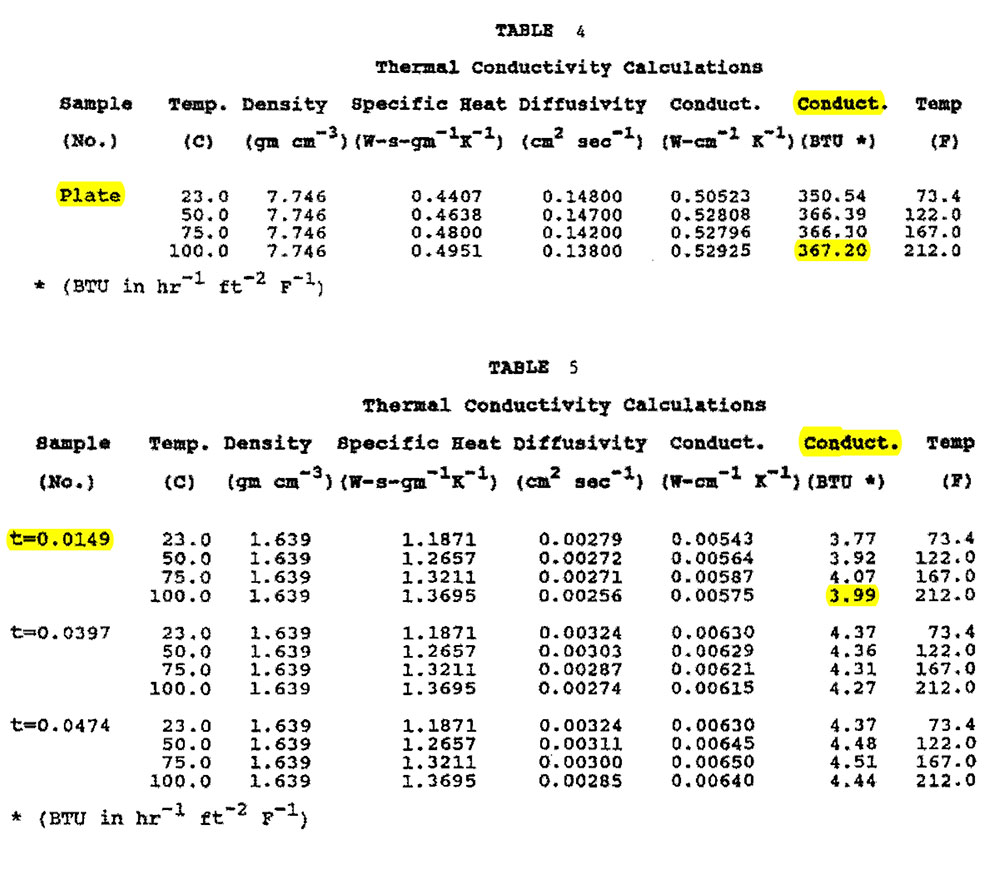

Super Therm BTU testing 1997

It was noted by Acheson J. Duncan, Department of Mathematical Sciences, The Johns Hopkins University on March 24, 1980 about the results from the 1977 testing report “It is unfortunate that the sampling procedure was not statistically designed for the study of the distribution of R-values for mineral fiber batt insulation commercially available in 1977, which was one of the primary objectives of the report. All that can be done now in this regard is to proceed as if certain sets of data are random samples from specific populations in which you are interested, checking this assumption against possible evidence of nonrandomness. I will discuss this further below. It is desirable that the report make the hypothetical very clear nature of its findings.” (Tye, Desjarlais, Yarbrough, & McElroy, 1980, pg 105).

Meaning, that samples used to test R-value came from one manufacturer and 3 different plants they own. Of the hundreds of recipients on the distribution of the report, Owens Corning had 11 recipients while the FTC only had 2 yet the ruling was made (Tye, Desjarlais, Yarbrough, & McElroy, 1980, pg 122) and very few other insulation companies were involved in our research.

The FTC Commissioners public discussion with regard to standard insulation materials association NAIMA (North American Insulation Manufacturers Assoc) who objected due to their interests in bulk insulation of claims suggesting insulation that limits air infiltration performs better overall than other insulation. Yet the FTC notes the significant concerns of bulk insulation “The Commission has long recognized that the Rule’s uniform R-value test methods do not account for all variables applicable to insulation performance. Despite the R-value rating’s limitations, it provides an important baseline from which consumers can compare various insulation products. The Commission has addressed these and related concerns repeatedly since it first issued the Rule in 1979. Indeed, there are a variety of factors not accounted for in R value tests, such as the design characteristics and geographic location of the building, the specific application in which the product is installed, outside and inside temperatures, air and moisture movement, installation technique, and others.” (Federal Trade Commission, 2018, p. 7).

How Bulk Insulation Works

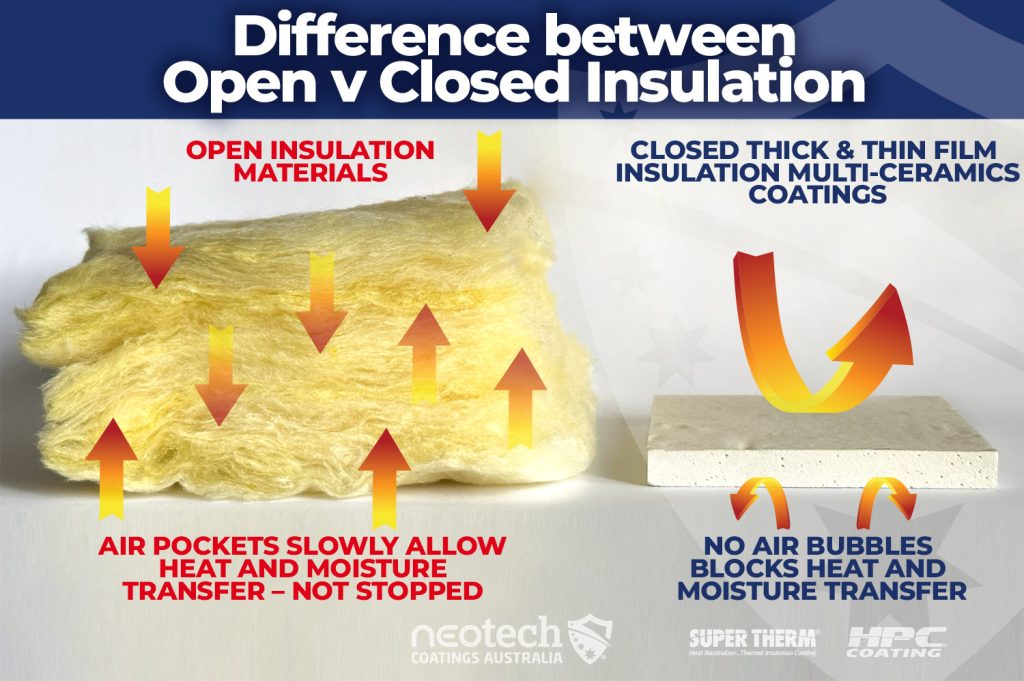

Bulk insulation works by trapping air within low-conductivity materials to slow the transfer of heat via conduction. Common types include:

- Fibreglass – Made of spun glass fibres.

- Rockwool – Mineral wool derived from volcanic rock.

- Polystyrene – Expanded or extruded plastic foam.

- Cellulose – Recycled paper, treated with fire retardants.

These materials rely heavily on air pockets. When compressed, filled with moisture, or poorly installed, performance plummets.

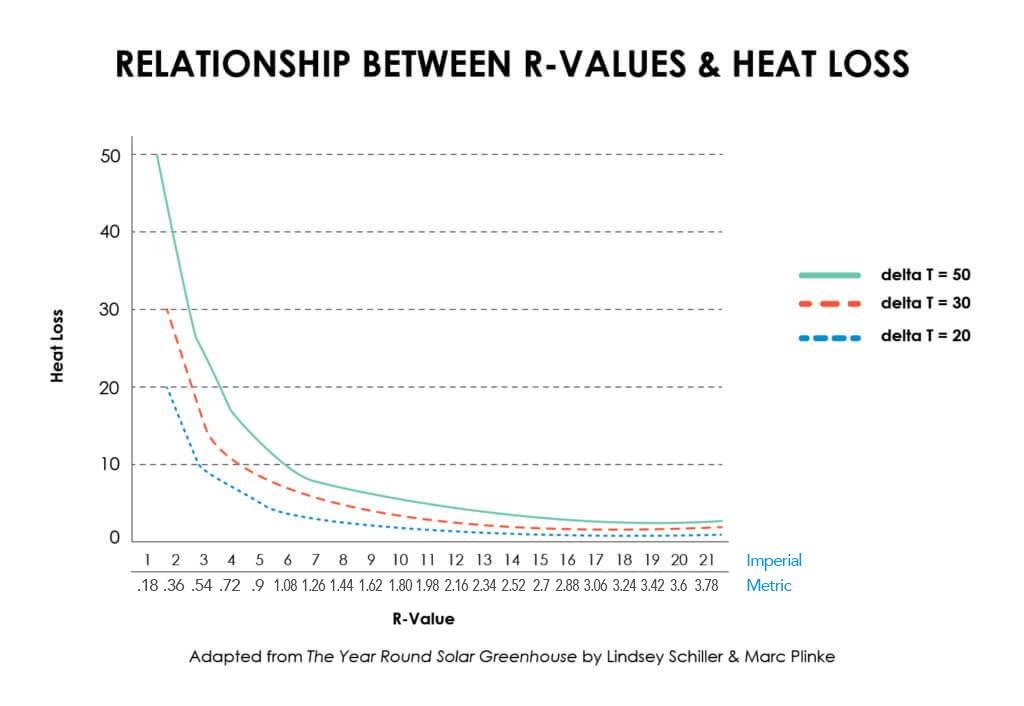

The Flaws of R-values: A Static Number in a Dynamic World

The R-value measures resistance to heat flow—in one direction, under lab-controlled conditions, using ASTM C518, C236 or ISO 8301. These tests assume:

- Constant interior/exterior temperatures

- No radiation or solar loading

- No wind, moisture, or humidity fluctuations

- Horizontal installation, fully enclosed cavity

But real-world buildings don’t work like that.

In a typical roof or wall assembly:

- Heat comes from radiation, not just conduction

- Surfaces absorb and store heat

- R-values ignore thermal lag, emissivity, and diffusivity

- Hot air can bypass insulation through gaps or convection loops

Key Weakness: R-values only measure how slowly heat moves once it enters. They don’t stop it from entering in the first place.

Major Performance Issues with Bulk Insulation

1. Installation Gaps and Poor Coverage

Even small gaps (5%) in batts can reduce performance by over 25%. Misaligned, sagging, or cut insulation can create heat bridges.

2. Compression

Bulk insulation relies on trapped air. If compressed (under a roof deck, pipes, or storage), it loses air space—therefore its insulating ability.

3. Moisture and Condensation

Fibreglass and rockwool absorb water over time. Wet insulation has drastically lower R-values and can:

- Lead to mould

- Damage timber

- Create a false sense of performance

4. Pests and Dust

Loose fill and batt insulation often become homes for vermin and collect fine dust, which can become a health hazard.

5. Landfill and End-of-Life Waste

Most bulk insulation ends up in landfill. Fibreglass and foam do not biodegrade and can leach chemicals over time. Fire retardants and binders often contain formaldehyde or other volatile compounds.

ASTM Testing Limitations

ASTM C518, C236 (and equivalents like ISO 8301) use a steady-state guarded hot plate method. Key limitations:

| Factor | Real-World Conditions | ASTM Lab Test Assumes |

|---|---|---|

| Heat type | Radiant, conductive, convective | Conductive only |

| Temperature | Dynamic, with solar peaks | Static delta T |

| Direction of heat | Top-down radiation, lateral transfer | Horizontal conduction |

| Air gaps or wind | Wind flow, stack effect | Still air |

| Moisture | Humid conditions, condensation risk | Bone dry, zero humidity |

| Sunlight exposure | High solar radiation | No radiation |

The Myth of “The More R the Better”

It’s a common trap: stacking R-values seems like stacking performance. But R-6 over R-3 doesn’t double real-world comfort if radiant heat is blasting through a roof. Without blocking radiation, bulk insulation still allows the heat to load onto the structure—then just slows its escape. In summer, this means your ceiling gets hot, your insulation gets hot, and your indoor space eventually follows and the air conditioning works harder. Plus at night the house is hot because heat is trying to escape.

Comparison Table: Bulk Insulation vs Super Therm®

| Feature | Bulk Insulation (e.g., Fibreglass) | Super Therm® |

|---|---|---|

| Primary Function | Slows conductive heat flow | Blocks 96.1% of solar heat (UV, visual, IR) |

| Emissivity | Low to medium | 0.91 – High: releases stored heat rapidly |

| Diffusivity | Not addressed | Engineered to resist thermal load penetration |

| Reflectivity | Varies – not core function | Reflects 92% of solar radiation, including 99% IR |

| Moisture Resistance | Poor to fair | Water-resistant (not waterproof), blocks humidity penetration |

| Compressed Performance Loss | High | Zero – thin film, non-compressible |

| Installation Complexity | High – cut, fit, seal, gaps | Easy spray or roll-on, adheres to surface |

| Lifespan | 10–20 years (depends on environment) | 20+ years, no degradation in heat block |

| Sustainability / Landfill Waste | High | Low – no end-of-life disposal if recoated |

| Fire Rating | Varies – may degrade over time | ASTM E84 Class A |

| Real-world Solar Heat Block | Low | Industry-leading at surface rejection |

The Role of Air-Based Insulation

Bulk insulation relies on air, but air is not a blocker—it just slows conduction. Under radiant heat, the air in the material heats up, stores heat, and continues radiating it inward. This is why buildings feel hot in the evening even when the sun’s gone.

Super Therm® prevents the heat from entering the structure in the first place. It works on the external envelope, keeping heat off walls, roofs, and ceilings altogether.

Where Bulk Insulation Fails in the 21st Century

- Dynamic Climate Conditions – Hotter summers, longer heatwaves, and higher radiant loads.

- Embodied Carbon – Manufacturing fibreglass, foam, and polystyrene is carbon intensive.

- Retrofits and Maintenance – In existing buildings, installing or upgrading bulk insulation is costly and invasive.

- Underperformance in Peak Load Events – R-values don’t account for 40°C+ days with UV and IR radiation cooking surfaces.

Super Therm®: Insulation for Insulation

Instead of fighting to increase R-values in a flawed system, Super Therm® complements bulk insulation by addressing the cause of heat gain—solar radiation.

Apply Super Therm® over the external surface, and you:

- Block 99% infrared heat (ASTM E1269, ASTM E1461)

- Avoid roof cavity heat load entirely

- Stop moisture, wind, and thermal stress from impacting bulk materials underneath

It’s why we call Super Therm® the insulation for your insulation. It doesn’t just delay heat—it blocks it.

Time for Smarter Building Science

We don’t live in a lab. We live in a climate that’s changing faster than the insulation industry wants to admit. R-values are useful—but limited. Bulk insulation has a place—but is no longer enough. If you want to reduce energy, protect buildings, and stay cool in the 21st century, it’s time to go beyond the batt.

Super Therm® doesn’t just meet the standards. It redefines them.