Zincalume isn’t a cool roof

There’s a common misnomer that Zincalume® roofs are cool roofs. When they are new they look shiny from the protective oils and the silver colour gives the impression they reflect heat. Zincalume® roofing is a combination of aluminium, zinc, magnesium alloy, and silicon materials which gives it a distinctive silver colour.

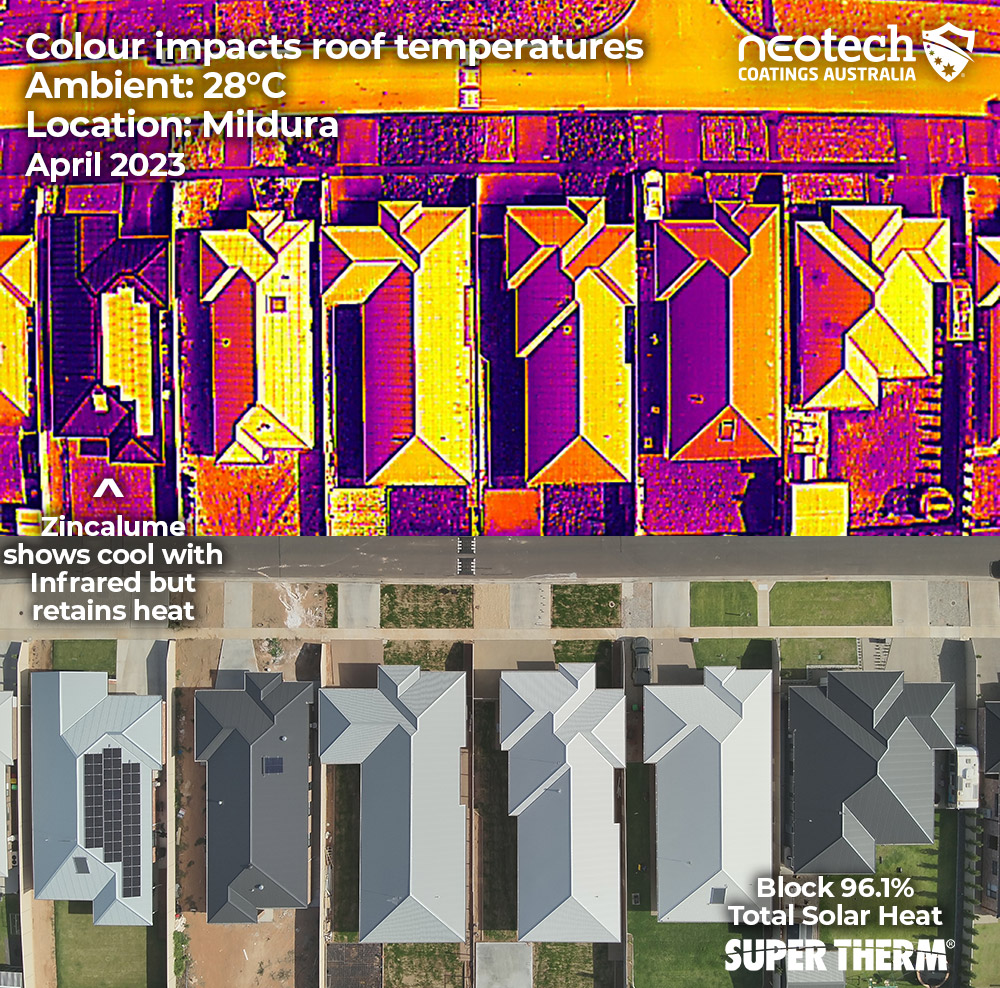

Infrared images show a different representation of an object’s temperature based on its emissivity, which is the ability to emit thermal radiation. While Zincalume® has a low (not good) emissivity, it reflects a significant portion of the visual light that falls on it due to the alloys and silicone. This means that it appears cooler in infrared photos than it actually is. The IR images don’t pick up emissivity.

The emissivity of Zincalume® can vary depending on the specific composition of the material, as well as factors such as surface finish and texture. However, in general, the emissivity of Zincalume® is considered to be relatively low, typically ranging from around 0.2 to 0.4. Super Therm®’s emissivity by comparison is 0.91.

This means Zincalume®’s low thermal emissivity ensures it is not very effective at radiating heat back into its surroundings. As a result, it tends to retain heat for longer periods than materials with higher emissivity values. This property can lead to excessive heat buildup in hot climates and transfer into the building roof space below, making it suitable for specific applications but problematic in others such hot environments.

The hot-dip galvanized surface has an emissivity of 0.20-0.30 compared to the emissivity of a normal steel surface of 0.60 average (source).

Oils aint oils

The oils on a new Zincalume® surface can have a slight impact on the material’s emissivity and heat reflection properties, but their effect is generally negligible. In fact the oils wear off the sheet after a few years then the first layer of protection is gone.

The purpose of the oils is to protect the Zincalume® coating during transport and storage, and they are typically removed during installation. While the oils can temporarily affect the surface’s appearance, they are not expected to significantly impact the material’s thermal properties.

Some types of oils, such as transformer oils, are specifically designed to be good electrical insulators, and are used to insulate and cool electrical equipment such as transformers and capacitors. These oils are typically made from highly refined mineral oil or synthetic materials, and are formulated to have high dielectric strength and low electrical conductivity.

However, other types of oils, such as cooking oils or lubricating oils, are not designed or intended to provide electrical insulation. These oils may have varying levels of electrical conductivity and may not provide effective insulation in electrical applications. Same with your roof. They provide very little thermal insulation to a Zincalume® roof.

Zincalume®’s heat reflection and emissivity properties are primarily determined by the composition of the coating and the surface’s texture and finish. As such, the oils are unlikely to have a significant impact on the material’s thermal performance, but it is always best to follow the manufacturer’s guidelines regarding surface preparation and maintenance to ensure optimal performance.

Total Thermal protection with Super Therm®

While Zincalume® is not typically used primarily for its thermal insulation properties, it is often used in roofing and cladding applications where reducing heat absorption and improving energy efficiency is a priority. In these applications, Zincalume® is often paired with additional insulation materials, such as rigid foam insulation or traditional insulation batts, to provide additional thermal protection. Yet does it? As we’re aware, bulk insulation provides resistance (R value) to heat but eventually it reaches heat flux and loads the heat into the building. Therefore Zincalume® is an affordable roofing material but doesn’t provide thermal protection…there’s a better way.

Zincalume® roofing has been thoroughly tested and design to withstand the elements. There is a reduced risk with advanced corrosion protection sealed into the coating system of a Zincalume® sheet and the exterior can be easily painted with Super Therm®. In fact many roofs are converted from heat absorbing to heat blocking barriers with just .25mm of Super Therm Thermal Insulation Coating.

This protects the roof even more from both corrosion and thermal shock along with the benefits of thermal insulation protection.

Super Therm® ceramic-based thermal insulation coating is designed to provide superior thermal protection for a wide range of surfaces, including metal roofs such as Zincalume®.

When applied to Zincalume® roofs, Super Therm® can help to reflect sunlight and reduce the amount of heat absorbed by the roof by as much as 96.1%, which can help to keep the building cooler and reduce energy costs for air conditioning.

Super Therm® is typically applied to Zincalume® roofs using a spray, roller or brush application method, and it can be customised to meet the specific needs of the project, such as providing additional UV protection or weather resistance extending the life of the roof over 30 years longer.

Some specific examples of Super Therm® being used to protect Zincalume® roofs include:

- A commercial building in Brisbane, Australia, that used Super Therm® to reduce the heat load on its Zincalume® roof and improve energy efficiency.

- A residential home in New Zealand that used Super Therm® to protect its Zincalume® roof from the harsh sun and salt spray in a coastal environment.

- A manufacturing facility in the United States that used Super Therm® to reduce heat absorption on its Zincalume® roof and improve worker comfort and productivity.

Overall, Super Therm® is a versatile and effective solution for protecting Zincalume® roofs and other surfaces from heat, weather damage, CO2 and rising energy costs.

Zincalume® is a registered trademark of Bluescope Steel Limited. Bluescope Steel developed Zincalume® as a corrosion-resistant steel product in the 1970s, and it has since become a widely recognized brand name in the construction industry for roofing and cladding applications.