Cool Surface Technology for the Darwin’s Heat Climate Change Emergency

City of Darwin

https://engage.darwin.nt.gov.au/climate

CLIMATE EMERGENCY DISCUSSION PAPER 2020-2030 Response

Shane Strudwick

Managing Director

NEOtech Coatings Australia

31 January, 2021

Contents

- Introduction

- Increased frequency and severity of heat events

- Heat mitigation through light colours

- Stopping the solar energy at the roof

- Need for heat resilient buildings in Australia

- Solar Reflective Index (SRI); a missing heat load factor

- Heat load on surfaces and roofs

- Heat transfer modelling through NatHERS extreme for Darwin

- The world acknowledges the need for cool roofs

- Heat load costs for transportation

- Risks from climate change regulations for Directors by ASIC

- Conclusion

- Resources

- About the author

- References

Introduction

The City of Darwin, like all cities around the world, is under the inevitable risk of climate change. Cities across Australia are undertaking policy development and strategies to work towards risk mitigation of climate change. As part of the City of Darwin’s Climate Emergency Discussion Paper 2020-2030, NEOtech Coatings Australia believe they have additional and further information as well as strategies for implementation that aim to achieve the City of Darwin’s goals of:

- Leadership and Governance

- Resilience and adaptation

- Energy efficiency and renewable energy

- Sustainable transport; and

- Circular economy

As part of the Discussion Paper, we would like to submit an important facet missing in the climate change conversation with regard to a Cool Surfaces and Roofs Technology Systems.

There’s a gap in Australia’s energy efficiency building strategies, urban heat island effect and ways to reduce CO₂ along with the wellbeing of humans and animals. These strategies are targeted towards both new and retrofitted buildings and aim to passively deliver energy savings between 20-50% (industry tested) that have been tested globally through leading ceramic heat block coatings. These coatings actively benefit climate change mitigation with a reduction in CO₂ emissions amongst other significant benefits listed below.

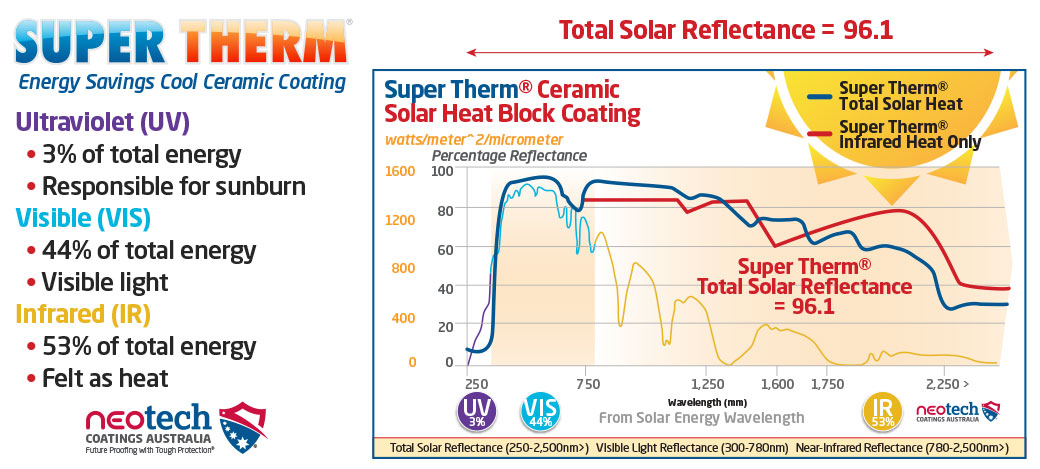

While there is some confusion regarding the net benefit of heat reflective paints and ceramic heat block coatings, NEOtech Coatings are able to conclusively provide extensive global testing and industry results that validate the substantial and significant benefits of its flagship coating Super Therm® Ceramic Heat Block Coating which has been proven to:

- Reduce CO₂ emissions

- Reduce energy consumption

- Fireproof (Tested by NASA)

- Blocks 95% of all solar heat

- Lasts over 30+ years

- Eco friendly and safe

- Easy to apply single application

- Total Solar Reflectance of 96.1 out of 100

Super Therm® has proven for over 30 years to stop 95% of heat. It contains 4 strategically formulated ceramics – two of the ceramics are reflective for UV and visual light, one acts as a non-conductor for emissivity and the fourth blocks the infrared solar heat energy making it a high performance and effective energy friendly solution. It is a water-based, single application product which harmonises a unique combination of highly effective urethanes, elastomeric acrylics and resin additives to produce a tough yet flexible coating that’s so far lasted over 30 years on a test performed by Japanese distributors in Kansas. Super Therm® is manufactured in the USA where it was developed with NASA between 1989 to 1995. The Japanese have applied over 7 million square metres of Super Therm® across leading industry and government buildings with significant energy savings, reductions in CO₂ and reduced their urban heat island effects.

It genuinely repels radiated heat like no other, reflects convective heat and blocks conducted heat. This heat load prevention on surfaces, roofs and walls greatly reduces temperatures and stops heat entering a building keeping it near ambient through non-mechanical cooling. This creates energy savings through reduced KW power use, reduced grid demands, better comfort, well being and sustainability. Ultimately Super Therm® resists the loading of surface heat over the envelope of a building to stop heat load before it starts and would assist The City of Darwin’s zero-net emissions targets even further along with dealing with climate change.

Increased frequency and severity of heat events

The City of Darwin has outlined a major concern regarding heat events and the impacts on health and well being, particularly vulnerable populations. Key infrastructure-related strategies that reduce heat stress include tailoring the design of new infrastructure, retrofitting existing infrastructure, and integrating green infrastructure as outlined on page 44.

Infrastructure design has a strong influence on the cooling needs of occupants and can decrease the need for mechanical cooling. Designing infrastructure to consider heat gain in the first instance is much less costly than retrofitting infrastructure. Significant opportunities exist to strengthen building codes to cost-efficiently improve thermal efficiency performance whilst protecting occupants from increased heat stress. This is particularly important for infrastructure designed for use by vulnerable individuals. In these cases, design can provide public cool places for respite. Appropriate designs can further dampen heat build-up in surrounding areas, which can mitigate the Urban Heat Island effect.

Retrofitting existing infrastructure can reduce the impacts of extreme heat, however, the level of improvement will depend on specific infrastructure design and location. In general, investment in improved thermal comfort in existing infrastructure that is currently unable to protect people from heat stress is a cost-effective preventative health measure. As such, when the health benefits are considered alongside the social, financial and environmental benefits of heat-appropriate infrastructure, a clear business case emerges for investing in thermal efficiency upgrades in existing infrastructure

We understand through this that the City of Darwin require solutions that:

- Passively insulate through heat load prevention

- Reduction of air conditioning and water consumption

- Improve thermal efficiency performance by at least 20-30% with proven testing

- Protect the wellbeing of all the population for both residential and commercial

- Safe and eco friendly

- Both for retrofit or new infrastructure

- Works in all environments

- Cost effective solutions

- Works alongside social, financial and environmental benefits

- Safe and easy application and long term benefits.

Heat mitigation through light colours

The Northern Territory Government was trialling a series of initiatives that are expected to reduce the impact of heat in Darwin and assist with revitalising the CBD. A heat mapping study undertaken in the Darwin CBD demonstrated high-level surface temperatures exceeding 60 degrees in some locations, including Cavenagh Street. Over an 18 month period, a number of heat mitigation methods were being trialled to improve the comfort in the city for residents, businesses and visitors. As part of the trials it was identified that light coloured and heat reflective road surface treatments to reduce pavement surface temperatures were included (Department of Infrastructure, Planning and Logistics, 2019).

The concept of light colours in hot climates is not new, however understanding how heat works is very important and we find it is largely misunderstood. This is the fundamental of our discussion paper submission and opportunity for the City of Darwin to consider a cool surface and roofs strategy and government leadership in this sector.

When we compare in Google Maps, Darwin’s use of cool roofs with the City of Parramatta there is a noticeable difference in light coloured roofs. While Darwin as a community understands the net gain of utilising cool roofs it is important to understand there are additional benefits by applying the right technology that gives sustainable, long term heat reflection and heat block coating products.

| v | ||

| City of Parramatta (Google Maps) | City of Darwin (Google Maps) |

Stopping the solar energy at the roof

The 2013 report by the National Climate Change Adaptation Research Facility, A Framework for Adaption of Australian Households to heatwaves authored by 23 leading Australian academics from the University of South Australia, University of Sydney and Queensland University of Technology recommended modifying roofs by increasing solar reflectance, adding reflective foils and increasing thermal insulation. While bulk insulation slows the heat load stopping the solar energy at the roof is the key.

Stopping the solar energy at the roof

before it enters the building is the key

Less bulk insulation is required with roofs which reflect more solar radiation, such as light-coloured roofs and those who have had foils applied. There is little doubt that bulk insulation within the roof has significantly reduced the cooling energy use in Australian homes. However, existing practices and regulations do not fully account for the actual heat transfer processes that occur, and Australia remains behind most of the developed world in this area (NCCARF, 2013).

The report continues according to the BCA (Building Code of Australia), the thermal resistance or R value of bulk insulation is based on AS/NZS 4859.1:2002 which requires measurement of the R value (resistance value) at 23°C. However, no consideration has been allowed in the BCA for the degradation of the R value due to temperature. As stated in AS/NZS 4859.1:2002, the R value can degrade by 0.49%°C which, during peak summer, can represent a reduction of 14% (NCCARF, 2013). We believe it is much more when you take into consideration ageing, moisture and poor installation.

Super Therm® was successfully tested at 23°, 50°, 75° and 100° celsius with the results proving it blocked 99.5% of all the BTU heat load from the hot side to the cold side at all temperatures. The rate of solar energy increase in the future will be extreme and bulk insulation will not and cannot work in the future; the hotter the better for Super Therm®.

The report recommended while bulk insulation slows the heat load, stopping the solar energy at the roof is the key. “The amount of solar energy which the roof absorbs is strongly dependent on the reflectivity of solar radiation from the roof which is related to the roof colour and its formulation. In southern Australia, the most popular roof colours for new houses for the last decade have been dark, with light-coloured roofs being least popular. In locations such as Brisbane and Darwin, light-coloured roofs have traditionally dominated; however, there is a concerning trend of dark-coloured roofs being used in some new homes”. Dark surfaces contribute to heat gains.

The amount of solar energy absorbed by the roof is a significant factor which determines the heat transmission into the dwelling

The amount of solar energy absorbed by the roof is a significant factor which determines the heat transmission into the dwelling during heat waves. The absorbed radiation is a function of the total solar reflectance (TSR) of the roof, which is the ratio of the reflected solar radiation to the total radiation incident on a surface. The range over which measurement is made is generally between either 280 or 300 nm and 2500 nm. A typical grey- or black-coloured roof has a TSR of around 0.05 to 0.1, and a white roof has a TSR of around 0.9. Overall, the defining parameter which determines the temperature rise of the roof surface compared to the ambient temperature is not the colour but the specified TSR (NCCARF, 2013). Super Therm® has been tested globally to be of the highest standards with a TSR of 96.1 plus it prevents heat loading onto the surface through one of its unique compounds.

Roof surfaces which absorb high amounts of solar radiation can readily reach temperatures of 80°C in hot weather. This temperature represents the driving force of the heat flow into the building. Roof surfaces which absorb low amounts of radiation can dramatically reduce this temperature, bringing it closer to the ambient temperature” (NCCARF, 2013). Super Therm® fits the exact requirements to block solar heat, therefore leaving roof temperatures ambient.

Need for heat resilient buildings in Australia

University of South Australia research associate Dr Gertrud Hatvani-Kovacs co-authored a paper calling for the Building Code of Australia to encourage designs that are heat stress-resistant. “Buildings were rated according to their annual energy consumption and while they may perform very well during winter time and consume much less for heating, their cooling demand was still relatively high” Gertrud said (Sutton & ABC News, 2018).

The Australian Government’s Nationwide House Energy Rating Scheme (NatHERS), The Australian Government Your Home: Australia’s Guide to Environmentally Sustainable Homes and the Building Code of Australia don’t take Cool Roofs into consideration or next generation heat block coatings and reflective paints technology.

Your Home acknowledges that 25-35% (Australian Government, n.d.) of heat gain comes through the ceiling of a home and yet the only reference in YourHome.gov.au to cool roofs and sustainability is the “shading of wall and roof surfaces is therefore important to reduce summer heat gain, particularly if they are dark coloured or heavyweight. Light coloured roofs can reflect up to 70% of summer heat gain” (Australian Government, n.d.). This highlights the urgent need to stop heat entering the envelope of buildings isn’t being considered. Actually a light coloured roof cannot reflect up to 70% of the summer heat gain alone. Below I discuss what SRI and emissivity is and you’ll see the YourHome.gov.au statement isn’t correct.

This highlights the urgent need to stop heat entering the envelope of buildings isn’t being considered and heat transfer isn’t understood

Given academic research and recommendation on utilising reflectivity of solar radiation to prevent heat load and the loss of efficiency of bulk insulation there will be increased demands and reliance on air conditioning. Inefficiently designed buildings means there will always be a release of waste heat into the atmosphere contributing to the urban heat island effect. As the world gets hotter, buying an air conditioner is ironically becoming the most popular individual response to climate change, and air conditioners are power-hungry appliances: a small unit cooling a single room, on average, consumes more power than running four fridges, while a central unit cooling an average house uses more power than 15. “Last year in Beijing, during a heatwave, 50% of the power capacity was going to air conditioning,” says John Dulac, an analyst at the International Energy Agency (IEA) (Buranyi, 2019).

The USA Energy Information Administration’s model uses population-weighted degree days as indicators of heating and cooling demand. Annual heating degree days measure how often and how far temperatures fall below 65 degrees Fahrenheit (18.3°C), indicating demand for indoor heat. Heating degree days have generally declined as temperatures have risen and as the U.S. population has moved to warmer climates. Conversely, cooling degree days (indicating days when average temperatures in a location exceed 65 degrees Fahrenheit) have generally increased (U.S. Energy Information Administration, 2020).

A presentation by Dr John Pockett from the Barbara Hardy Institute, University of South Australia on ‘Cool Roofs and Heat Reflective Paints’ stated ‘cooling efficiency is much less that heating and falls off very quickly as the ambient temperature increases, being about half its maximum when we have a very hot day.’ (Pockett & UniSA, n.d.). This indicates that air conditioners need to work twice as hard the hotter it gets pulling in hot ambient air to convert to cool air, therefore doubling power consumption the hotter it gets.

Air conditioners stacked on top of each other are drawing hot air even more like a wall of fire. Knowing there’s an imminent increase globally in air conditioning sales and consumption and therefore CO2 emissions a smart and strategic strategy in non-mechanical cool surfaces and roofs with proven, long term benefits is urgently needed to combat future heat challenges. This also reduces the reliance on mechanical, energy consuming cooling towards passive solutions.

Air conditioners are only made to cope with 48°c

Tawar Razaghi’s article ‘Why airconditioning units fail to work on hot days in outer suburbs’ “In summer, a lot of the aircons break down because they’re overheating. They’re only made to cope with 48 degrees,” Mr Halabi said, director of ACE Air Solutions. “On the side of the houses if it’s blowing 50 or 60 degrees it’s getting a lot hotter than it’s built to handle.” (Razaghi, 2021). This goes to highlight if the temperatures begin to grow further, air conditioning technology may not be able to provide cooling solutions. Passive heat blocking will be critical to support mechanical cooling.

While the City of Darwin’s focuses heavily on energy efficiency and renewable energy has significant merits and those actions are absolutely necessary, part of the focus on sustainability that converts into passive energy efficiency and non-mechanical solutions are critical. Heat block coatings that are proven to meet the tough criteria, like Super Therm® offer simple and passive solutions amongst the sea of complex issues related to zero-emissions cool surface technologies. Getting humans to minimise use of power is as much as an important outcome while finding ways to sustainability secure supply. Reducing heat load is a very important key to energy consumption reduction.

Con Edison the New York electricity company supplies more than 10 million people in the New York area. It’s grid, with 62 power substations and more than 130,000 miles of power lines and cables across New York City and Westchester County, can deliver 13,400MW every second. This is roughly equivalent to 18m horsepower. It’s fair to say they understand the needs of energy consumption in major cities (Buranyi, 2019). There are net energy consumption gains as Con Edison research from New York stated “keep your thermostat set at 78°F (25.5°C) when your building is occupied…turning down the thermostat to 75°F (23.8°C) costs 18% more, and 72°F (22.2°C) costs 39% more!” (ARISTA Air Conditioning Corp, 2015).

Therefore BTU Reduction = KW savings = actual dollar savings…keeping out as much thermal heat load as possible saves energy and saves money

Solar Reflective Index (SRI); a missing heat load factor

To understand heat, it’s important to understand the differences between reflectivity, emissivity and heat load that make up the Solar Reflective Index or SRI in heat reflective paints and heat block coatings. SRI is determined through solar reflectance and thermal emissivity. Solar Reflectance or reflectivity is about light and not the total sum for blocking heat. White paint has 70% reflectivity, which means it reflects 70% of visual light which is 44% of the total radiation heat. Meaning white paint reflects 30% of the total heat not 70%. This means 70% is actually loading into the substrate.

See our infographic for heat load and SRI

Your Home through the Australian Government stated: “Light coloured roofs can reflect up to 70% of summer heat gain”. This example changes that misinformation and we assume ‘light colours’ means white.

The first part of SRI is the solar reflectance or reflectivity. For example, on a 28°c day, the bonnet of a white car is 53° and a black car is 73°. If the white paint blocked 100% of the heat, the temperature of the car would be 28° or ambient. If the white paint reflected 70% of the ‘solar heat’ it would make the bonnet 37°. In fact because it is 30% reflection of heat it is close to 50° which is correct. The white paint doesn’t block infrared heat which is 53% (Glass, n.d.) of the total radiation heat from the sun.

Once the heat is loaded into a surface, it maintains that heat load which is the heat that can burn your skin to touch. In fact only 30% maximum reflection from white paint is possible if it is clean. The Super Therm® temperature would be cool to touch on top. When high reflective paint is applied, it is important the ageing of performance should be considered. A study by Yasushi Kondo from Musashi Institute of Technology for the Tokyo Metropolitan Government, Japan Testing Center for Construction Materials in 2006 on 21 heat reflective paints showed even the most reflective paint lost it’s solar reflectance by 44% within just 1.5 years. It was also noted, however there is no authorised standard for performance of high reflective paints in Japan. A standard or qualification system should be considered in Japan (Kondo, 2006).

The infrared heat (53%) penetrates through the white car’s paint and loads into the metal because of the metal’s density which is the same as a metal roof on a building…but also tiles, concrete etc. A piece of paper isn’t hot at the same temperature because it lacks density. So in reality, reflectivity testing is about only some of the nanowaves for visual and partial infrared heat but not all the full heat wave spectrum.

The other part of SRI, is thermal emissivity which is the infrared heat not blocked but re-emitted from the substrate through the paint that’s allowed it to already be absorbed. Emissivity is measured against a black surface which absorbs 100% or the value of 1.0 of the heat “load” and then released back to the atmosphere which is the equalised balance of heat load or 100% of the heat.

If an emissivity rating is .92, does it mean that 92% of the heat load that was absorbed into the surface is thrown off the surface again reducing the heat absorbed and transferred to the cool side, not at all. No matter the emissivity number, the surface loads all the heat which then transfers through.

The essence of energy savings long term is blocking the heat load

The concept of an emissivity rating is like having an umbrella made from a flyscreen that allows 100% of the rain through while trying to measure how quickly you can dry while still being rained on. This is how the Solar Reflective Index is determined through reflectivity and emissivity…it doesn’t add up or connect to the purpose of blocking heat for true energy efficiency. The essence of energy savings long term is blocking the heat load, nothing more…so it is highly important to understand heat load is the key.

There is a 4 step process for solar heat or thermal emittance to load into a building

- Solar Radiation: The sun’s heat hits the surface or roof with visual light (44%), UV (3%) and Infrared (53% of heat nanowave spectrum)

- Solar Reflectance (SRI Step 1): Tests are conducted for the reflectivity for some of the nanowaves spectrum of visual and infrared heat. The whiter the coating, the better. The rest of the heat loads through the surface into the substrate

- Thermal Emittance (SRI Step 2): Once the heat is loaded, emissivity measurements are taken for relative ability of a surface to release or re-emit the heat back out after the heat is loaded

- Heat Load: The remaining loaded heat is converted into conduction or infrared heat and is transferred into the building.

Therefore the Solar Reflective Index (SRI) doesn’t give the whole picture of heat loading into the substrate and is missing a vital piece of data on how much heat is transferred or loaded. Super Therm® only allows 5% of heat to load. Virtually all heat reflective paints rely on SRI for their rating yet still allow vast amounts of infrared heat through their coating into the building.

The true judge of “heat resistance” paints and coatings is testing that shows it’s performance in blocking and preventing the absorption of the heat load, even when dirty. When you touch the bonnet of the white car or roof you’re not meant to burn and this shows the heat load into the material’s density or equivalent to the BTUs into a building, then you’ll truly know heat is not transferred.

Heat load on surfaces and roofs

When heat penetrates a roof as shown above, no matter the substrate material it heats up the roof space with 100% of the conducted heat unless it’s blocked. Dark surfaces are even worse for heat transfer and attract at least 30% more heat over white surfaces. Hence the dark car was 20° hotter than the white car. Traditionally this is absorbed by the bulk or fibreglass insulation during the day which stores the heat until it’s full, then once full and at night, it releases the heat to the cool side of the building, traditionally where the air conditioning is. It’s similar to a bucket of water that’s full. The overflowing water spills out of the bucket which is exactly what heat does once insulation is fully loaded. That’s why houses and buildings are hotter at night, due to heat load stored in bulk insulation.

So in effect, bulk insulation is contributing to the increased cost of energy use in buildings and when the heat is pushed back to the built environment is contributing to the urban heat island effect. Interestingly Dr John Pockett from the Uni SA notes ‘exposed metals (Zincalume and galvanised) are poor at giving off heat so they become hotter than most other materials having the same TSR – Total Solar Reflectance (Pockett & UniSA, n.d.)

An article by Tanya Roe, Senior Consultant, Sustainability, City of Adelaide “Using seal coats to reduce urban heat“ stated in 2018 the Resilient East climate change partnership (eight councils in central-eastern Adelaide plus the Government of South Australia), along with the City of Salisbury, commissioned The Collaborative Heat Mapping for the Eastern and Northern Adelaide Project. A key finding from the study was that non-shaded asphalt roads are 4°C hotter than the average land surface day temperature, and they bank the heat and release it at night, becoming the hottest night-time surface (Roe & City of Adelaide, 2020).

Tanya states “hard surfaces typically account for the urban heat island effect in cities. Roofs typically account for 20-25% and pavements 40% of city surfaces, each absorbing 80% of sunlight reaching them and converting it into heat. There’s a range of cool materials being used, trialled and developed, which include low heat conductivity (conducts heat less into its interior), low heat capacity (stores less heat in its volume), high solar reflectance (albedo) and a high level of embodied moisture to be evaporated or filtrated into the soil.” The Adelaide City Council is in consultation with NEOtech Coatings regarding a program of use for Super Therm® Heat Block Coating along with the University of Adelaide involvement.

Urban heat island amongst other serious consequences produces higher air pollution, increased nighttime heat, increased urban temperatures and higher energy consumption and also adversely affects human health. Humans are negatively impacted because of increased general discomfort, exhaustion, heat-related mortality, respiratory problems, headaches, heat stroke and heat cramps. Urban heat islands can also worsen the impacts of heatwaves (Conserve Energy Future, 2017).

To show the serious nature of UHI effects in cities globally, the US introduced the Preventing Health Emergencies and Temperature-related (HEAT) Illness and Deaths Act of 2020 (Wiltshire-Gordon & U.S. Green Building Council, 2020). The proposed legislation aims to statutorily authorise the National Integrated Heat Health Information System Interagency Committee (NIHHIS) to address extreme heat in the United States. The HEAT bill would also establish a $100 million community heat resilience grant program within NIHHIS to support urban climate mitigation efforts. Projects eligible for grants include those using cool roofs, cool pavements, urban trees and building HVAC (Heating, Ventilating, and Air Conditioning) retrofits.

Research from the Smart Surfaces Coalition in the US shows that implementing citywide smart surfaces like cool roofs, green roofs, solar roofs and permeable pavements could reduce urban heat by 3-5 degrees, cut greenhouse gas emissions by up to 15%, create 250,000 local jobs, and save cities $700 billion in energy and health costs over the next three decades (Smart Surfaces Coalition, 2018).

Heat transfer modelling through NatHERS extreme for Darwin

Roof surfaces which absorb high amounts of solar radiation can readily reach temperatures of 80°C in hot weather. This temperature represents the driving force of the heat flow into the building. Roof surfaces which absorb low amounts of radiation can dramatically reduce this temperature, bringing it closer to the ambient temperature (NCCARF, 2013).

Existing practices and regulations do not fully account for the actual heat transfer processes that occur, and Australia remains behind most of the developed world in this area. The implementation of NatHERS and the application of the building modelling engine, AccuRate, represent a move away from a prescriptive approach and have allowed designers to consider the full range of options for reducing the cooling energy requirements in buildings (NCCARF, 2013). To demonstrate the significance of these steps, modelling was conducted in AccuRate of two energy-efficient homes representative of a typical house in 2030 with different roof insulation properties, in a variety of cities in Australia.

Above shows the total forecast energy use for different roofing systems in different locations around Australia. Although the majority of homes in Darwin and Brisbane will continue to have light-coloured roofs and have a high TSR, the significant impact of ignoring the TSR cannot be overstated. For both houses in Darwin, an increase of 15% occurred between the expected and more likely roof scenarios. However, it should be noted that latent cooling in Darwin represents 50% of the cooling requirements, which means that any design measure will equally have a smaller impact and, therefore, such an increase could be argued to be relatively significant (NCCARF, 2013).

A smart and strategic strategy in cool roofs with proven, long term benefits is urgently needed to combat future heat challenges

The world acknowledges the need for cool roofs

Victoria, Australia

The Victorian Energy Saver Program states cool roofs are reflective surfaces designed to reflect more solar radiation and absorb less heat than a standard roof (Environment, Land, Water and Planning; State Government of Victoria, 2018). This reduction of energy in the form of BTUs into a building reduces the demand on energy consumption.

California, USA

An article on a study out of Berkeley Lab in California, which concluded that white roofs outperformed black roofs economically as well as environmentally. It called for the phasing out of dark roofs in hot climates, especially those prone to heatwaves. This would save energy costs, protect against the urban heat island effect and tackle climate change (The Fifth Estate, 2017).

Cape Town, South Africa

A first of its kind project in South Africa is being spearheaded by the South African National Energy Development Institute (SANEDI), with the rolling out of 26,000m² of cool roofing technology in the City of Cape Town as part of the Cool Roofs and Insulation Collaboration. Without needing to power mechanical cooling systems, cool roofs with insulation offer significant cooling to South African homes in the heat of the summer. Denise Lundall, project officer for energy efficiency at SANEDI explained “We want to show how powerful passive cooling is when cool coatings are used in conjunction with insulation. For example, cool coatings can significantly cool a home equivalent to the cooling capacity of a four-times thicker insulation layer. A quadrupled insulation layer would be incredibly costly, with a 19- to 21-year return on investment. A cool coat on a roof with standard insulation would offer the same cooling as a four-times thicker insulation at a fraction of the cost.” (Building & Decor, 2020).

Tokyo, Japan

The C40 Cities Climate report states “surface solutions are often readily deployable, simple, and cost-effective technologies available throughout the world. A cool roofing surface is both highly reflective and highly emissive to minimize the amount of light converted into heat and to maximize the amount of heat that is radiated away. Most existing roofs are dark and reflect no more than 20% of incoming sunlight, while a new white roof reflects about 70 to 80% of sunlight (sic not 70% of heat). Because of this, new white roofs are typically 28 to 36°C cooler than dark roofs, while aged white roofs are typically 20 to 28°C cooler. In addition to cost savings from reduced air conditioning, cool roofs also improve the life of the roof and performance of rooftop equipment, such as solar PV panels” (C40 Cities, 2016).

New Delhi, India

A report by the Natural Resources Defense Council and partners in India, roofs offer an avenue to significantly impact internal temperatures and provide indoor thermal comfort, in both air-conditioned and non-air-conditioned buildings. Cool roofs, with their specific characteristics, are better at reflecting solar radiation and emitting absorbed heat. Depending on the setting, these cool roofs can help keep indoor temperatures lower by 2 to 5°C (3.6 – 9°F) as compared to traditional roofs, offering simple and effective protection from extreme heat especially for vulnerable communities in low-income housing. Cities can lead the way in cool roof implementation. In 2017 and 2018, the cities of Ahmedabad and Hyderabad in India, initiated pilot cool roof programs. These initial programs include citizen awareness campaigns, pilot initiatives targeting 3,000 roofs, cooperation with businesses, and applying cool roof techniques to government buildings and schools (Natural Resources Defense Council – India, 2018).

Heat load costs for transportation

Super Therm® also helps, trucks, buses and more save money, energy and improve comfort. Independent industry tests have shown for example refrigerated trailer units’ fuel consumption is reduced by approximately 30% versus a multi-temp refrigerated unit with traditional aluminium roofs. There was a 40% reduction in waiting time for reefer trucks to cool down before transportation.

In the trucking/package delivery industry, heat related claims are a major cost due to damaged goods and heat stress related employee claims. Worker productivity is reduced due to discomfort both for the drivers and the employees that load and unload the trailers. With Super Therm® a bus test in Mexico, the Thermo King unit only needed 33.4 minutes to reach 29ºc, 45% less running time than without using Super Therm®. Less running time equals less fuel, reducing both costs and CO₂ emissions (NEOtech Coatings Australia, 2020)

Risks from climate change regulations for Directors by ASIC

ASIC commissioner John Price said, ‘Climate change is an area which ASIC continues to focus on. The updates to our regulatory guidance, together with the publication last year of Report 593, round out ASIC’s response to the Senate Report on Carbon Risk. ‘While disclosure is critical, it is but one aspect of prudent corporate governance practices in connection with the mitigation of legal risks. Directors should be able to demonstrate that they have met their legal obligations in considering, managing and disclosing all material risks that may affect their companies. This includes any risks arising from climate change, be they physical or transitional risks.’ Mr Price said (ASIC, 2019). Australian businesses and Directors will be held responsible for also managing risks arising from climate change. Cool surfaces and roofs will become part of those strategies particularly for worker well being and productivity.

Conclusion

Darwin is likely to experience a significant increase in cooling requirements, going up by 51% by 2050 (NCCARF, 2013). Almost 75% of days per year in Darwin are already hot enough to have a ‘high impact with most of the population feeling moderate to acute discomfort’ (City of Darwin, 2020). Inclusion of a Cool Surfaces and Roofs strategy as part of the Climate Emergency Discussion Paper 2020-2030 will assist in the goal towards better management of climate change for the City of Darwin but more importantly it will assist in CO₂ reduction, improve the well being of the cities residents, reduce running costs and increase asset values of buildings for the long term.

The City of Darwin has an opportunity to showcase and lead the way in Australia to build advanced yet passive sustainability measures that stop heat entering buildings through the roof and walls while developing solar initiatives and other energy efficiency strategies. Many countries around the world are already developing advanced Cool Surface Technology strategies, yet many governments in Australia and the building codes are very, very slow to react to this simple solution.

The number one heat management strategy is stopping the heat load. Super Therm® has been proven and tested to outlast, out perform and provide outstanding energy efficiency solutions for over 30 years globally. Next generation Cool Surface Technology that stops heat load will become the next phase of solutions for climate change emergencies. Originally it was bulk insulation, then light coloured roofs now it’s about stopping as much solar heat as possible and Super Therm® blocks 95% of solar heat leaving your buildings with ambient temperatures where you can better manage internal comfort, energy demands along with overall grid supplies into the future.

Thank you for allowing NEOtech Coatings Australia to contribute to the City of Darwin’s Climate Emergency Discussion Paper 2020-2030. We are happy to be contacted for more information or present any further details to the City of Darwin.

Resources

- Heat Load & SRI Infographic

- Urban Heat Island effect and Cool Roofs Video

- Department of Energy USA – Testing Results 20-50% energy savings

- Cool Energy Kits – Roofing, Transportation and Agriculture

- About Super Therm Ceramic Solar Heat Block Coating

About

Shane Strudwick is Managing Director of NEOtech Coatings Australia, a provider of specialised high performance and technologically advanced coatings for government, industry and private projects. NEOtech are Australia’s sole SPI Coatings USA Distributors. Further information about NEOtech Coatings Australia or Shane can be obtained from the website neotechcoatings.com or Linked In.

LinkedIn: linkedin.com/in/shanestrudwick

Website: neotechcoatings.com

Mobile: 0409 678 654

Email: shane@neotechcoatings.com

Postal Office: PO Box 54, Stepney SA 5069, South Australia

References

ASIC. (2019, December 8). 19-208MR ASIC updates guidance on climate change related disclosure | ASIC – Australian securities and investments commission. ASIC ASIC – Australian Securities and Investments Commission. https://asic.gov.au/about-asic/news-centre/find-a-media-release/2019-releases/19-208mr-asic-updates-guidance-on-climate-change-related-disclosure/

Australian Government. (n.d.). Glazing. Retrieved September 6, 2020, from https://www.yourhome.gov.au/passive-design/glazing

Australian Government. (n.d.). Insulation. Retrieved September 6, 2020, from https://www.yourhome.gov.au/passive-design/insulation

Australian Government. (n.d.). Shading. Retrieved September 6, 2020, from

https://www.yourhome.gov.au/passive-design/shading

Building & Decor. (2020, December 10). Cape Town settlements get cool roofs this summer. https://www.buildinganddecor.co.za/cape-town-settlements-get-cool-roofs-this-summer/

Buranyi, S. (2019, September 6). The air conditioning trap: How cold air is heating the world. the Guardian. https://www.theguardian.com/environment/2019/aug/29/the-air-conditioning-trap-how-cold-air-is-heating-the-world

C40 Cities. (2016, February 15). C40: C40 good practice guides: Tokyo – thermal-barrier coating and water-retentive pavement. Retrieved from https://www.c40.org/case_studies/c40-good-practice-guides-tokyo-thermal-barrier-coating-and-water-retentive-pavement

City of Darwin. (2020). Draft climate emergency response | Engage Darwin. Engage Darwin | Homepage. https://engage.darwin.nt.gov.au/63409/widgets/317965/documents/188065

Conserve Energy Future. (2017, October 13). Effects and solutions to urban heat island. Retrieved from https://www.conserve-energy-future.com/effects-solutions-urban-heat-island.php

Department of Infrastructure, Planning and Logistics. (2019, January). Cavenagh Street Heat Mitigation Trial https://dipl.nt.gov.au/__data/assets/pdf_file/0004/649228/FACTSHEET-Cavenagh-Street-Heat-Mitigation-Trial-Stage-2-FAQs-1.pdf

Glass, V. A. (n.d.). How Low-E glass works. Glass Education Center | Vitro Architectural Glass. Retrieved September 19, 2020, from https://glassed.vitroglazings.com/topics/how-low-e-glass-works

Kondo, Y., & Musashi Inst. of Tech. (2006). Current State and Future Prospects of Cool Roof in Japan. https://www.coolrooftoolkit.org/wp-content/uploads/2012/04/Cool-Roofs-in-Japan-Kondoh.pdf

Natural Resources Defense Council – India. (2018). COOL ROOFS Protecting Local Communities and Saving Energy. NRDC. https://www.nrdc.org/sites/default/files/ib_-_cool_roofs_-_hyd_workshop.pdf

NCCARF – National Climate Change Adaptation Research Facility. (2013). A framework for adaptation of Australian households to heat waves. https://neotechcoatings.com/wp-content/uploads/2021/01/Saman_2013_Adapting_households_to_heat_waves-libre.pdf

NEOtech Coatings Australia. (2020, December 30). Truck reefer & bus heat block coatings solutions. NEOtech Coatings Australia | Leading Heat Block and Protective Coatings. https://neotechcoatings.com/protective-coatings/industry-uses/transportation/

Pockett, J., & UniSA. (n.d.) Cool Roofs and Heat Reflective Paints presentation. https://neotechcoatings.com/wp-content/uploads/2021/01/Cool-roofs-and-Heat-Reflective-Paints-John-Pockett-Uni-SA.pdf

Razaghi, T. (2021, January 25). Why airconditioning units fail to work on hot days in outer suburbs. Domain. https://www.domain.com.au/news/how-air-conditioning-units-fail-to-work-on-hot-days-in-outer-suburbs-1019865/

Roe, T., & City of Adelaide. (2020, August 17). Using seal coats to reduce urban heat. Retrieved from https://infrastructuremagazine.com.au/2020/08/07/using-seal-coats-to-reduce-urban-heat/

Rosone, M. C., & ARISTA. (2015, June 25). 15 tips to keep your energy bills from Skyrocketing this summer. Retrieved from https://aristair.com/blog/15-tips-to-keep-your-energy-bills-from-skyrocketing-this-summer/

Smart Surfaces Coalition. (2018, June 25). Smart surfaces: Stay cool save cash Whitepaper — Smart surfaces coalition. https://smartsurfacescoalition.org/analysis/stay-cool-save-cash-whitepaper

State Government of Victoria. (2018, July 31). Insulation and cool roofs. Victorian Energy Saver. https://www.victorianenergysaver.vic.gov.au/energy-advice-for-business/managing-your-energy-consumption/equipment-and-technologies-case-studies-and-guides/insulation-and-cool-roofs

Sutton, M., & ABC News. (2018, January 4). Modern homes trapping heat ‘like a plastic bag’. Retrieved from https://www.abc.net.au/news/2018-01-04/australian-houses-losing-in-heat-management-design/9287188

The Fifth Estate. (2017, February 9). Cool roofs V dark roofs – special report. Retrieved from https://www.thefifthestate.com.au/innovation/design/cool-roofs-versus-dark-roofs-special-report/

U.S. Energy Information Administration (EIA). (2020, March 13). EIA projects air-conditioning energy use to grow faster than any other use in buildings – Today in energy – U.S. Energy Information Administration (EIA). https://www.eia.gov/todayinenergy/detail.php?id=43155

Wiltshire-Gordon, S., & U.S. Green Building Council. (2020, August 21). New federal bill supports heat island mitigation. Retrieved from https://www.usgbc.org/articles/new-federal-bill-supports-heat-island-mitigation