Barron River Bridge – Protecting Macalloy Bars with Rust Grip®

Industry: Bridges, Infrastructure, Marine and Transportation,

Location: Barron River, Kuranda, North Queensland

Products: Rust Grip® and Corrosion Encapsulation

Global Partner: SPI Coatings

Corrosion Encapsulation and Brittle Fracture Risk Management

Overview

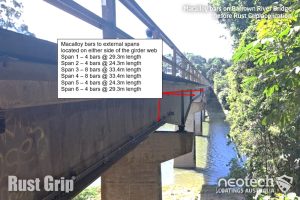

The Barron River Bridge (Kuranda, near Cairns, North Queensland) is a 62-year-old steel girder structure carrying more than 8,000 vehicles a day on the Kennedy Highway. After six decades in service, inspections revealed corrosion and wear in the bridge’s external 32 mm Macalloy post-tensioning bars – structural elements critical for preventing brittle fracture in the original steel girders.

These bars were retrofitted in 1963 after the Kings Bridge collapse to reduce tensile stresses in the brittle steel. They remain essential today. If even one bar snaps, the consequences are severe: damage to the girder, bridge closure, traffic disruption, and significant economic impact.

The Queensland Department of Transport and Main Roads undertook a full corrosion-prevention program and turned to for the ideal solution Rust Grip® for the critical Macalloy bars future protection.

The Problem

Detailed inspections identified:

- Widespread corrosion pitting, with depths up to 2.25 mm

- Localised severe pitting hidden under clamps – the deepest measured at 1.9 mm

- Vibration wear where bars rubbed against stiffeners and clamps

- Degradation of the old red-lead coating

- High tension in the bars, making them susceptible to brittle fracture if corrosion progressed

Laboratory testing confirmed the risk. Corroded bars showed reduced ductility – some fractured with only one-third of normal elongation. Simulated pits up to 5 mm deep also demonstrated reduced strength and snap-without-warning behaviour.

Corrosion was most severe directly over the Barron River, where moisture exposure and wind patterns created a more aggressive microclimate.

Environmental Constraints

Full bar replacement or abrasive blasting was not feasible in the short term due to:

- Working directly above the Barron River

- Need to avoid releasing debris, red-lead residue, or blasting media into the water

- Limited access windows and wet-season conditions

- Safety risks associated with de-tensioning highly stressed bars

A protective system was required that:

- Could be applied in situ,

- Did not require blasting,

- Encapsulated corrosion and sealed pitting,

- Prevented further deterioration and vibration wear,

- Maintained structural reliability until the bridge is replaced in the next decade.

Why Rust Grip® Was Selected

Rust Grip® was chosen as the primary encapsulation system because it met all critical criteria:

- Compatible over existing red-lead coatings – no blasting needed

- Moisture-cured urethane that penetrates and locks onto steel

- Aluminium-reinforced barrier that seals corrosion pits and prevents oxygen/water ingress

- High-adhesion, high-tensile coating ideal for stressed steel members

- Safe to apply using under-bridge access equipment

- Allowed the bridge to remain operational during works

At clamp locations, the system was reinforced using Rust Grip® + Denso tape wrapping, eliminating metal-to-metal contact and stopping vibration wear – one of the original causes of bar deterioration.

The Solution

In 2024, the Queensland Department of Transport and Main Roads undertook a full corrosion-prevention program:

- Rust Grip® encapsulation of every accessible Macalloy bar

- Denso wrapping at clamps to eliminate vibration wear

- Removal of clamps to inspect hidden areas for deeper pitting

- Protection targeted especially at the river-exposed spans where deterioration was most aggressive

This approach stopped further corrosion, stabilised the bars, and maintained structural integrity without intrusive or environmentally risky work methods.

Outcome

The protective coating program:

- Controlled corrosion on irreplaceable post-tensioning bars

- Reduced the risk of brittle fracture

- Avoided disruptive bar-replacement works during the wet season

- Allowed the bridge to safely return to full two-lane operation

- Ensured the bars remain serviceable until a future replacement bridge is constructed

Why This Matters

This project demonstrates the practical value of Rust Grip® for ageing infrastructure where:

- Components cannot be removed,

- Abrasive blasting is unsafe or environmentally unacceptable,

- Corrosion must be stabilised without compromising structural capacity,

- The asset must remain operational.

By encapsulating the Macalloy bars rather than disturbing them with Rust Grip®, the program delivered a safe, fast, and environmentally responsible solution for a critical transport link. A replacement bridge is under development.