Groundbreaking Energy Efficiency: Georgia-Pacific’s HPC® Coating Wins EPA ENERGY STAR Award

Industry: Industry High Process Heat

Location: Pennington, Alabama, USA

Products: HPC® Coating

Global Partner: Superior Products International II, Inc.

In an era where sustainability, energy efficiency and cost control are paramount for transforming business, the current methods of insulation are failing HPC® Coating is standing out from the newbies.

The advent of proven and long established ceramic thermal insulation coatings represents a monumental shift in mining and energy sustainability practices. One of the most notable breakthroughs in this field comes from Superior Products International II, Inc., with their HPC® Coating. This innovation has not only earnt a first with the prestigious EPA ENERGY STAR Energy Saving Award but has also set a new standard in addressing the perennial issue of corrosion under insulation (CUI), decarbonisation and cost savings.

Award-Winning Innovation

The recognition of HPC® Coating by the US Environmental Protection Agency (EPA) underscores the significant energy savings and environmental benefits HPC® Coating brings to the table. Applied at Georgia- Pacific’s Naheola paper mill digester tank, it achieved an impressive 49% reduction in energy consumption, amounting to annual savings of $332,000. This accomplishment highlights the potential of HPC® Coating to transform energy efficiency across many industries.

A New Era of Insulation Technology Stops CUI

HPC® Coating distinguishes itself from traditional insulation solutions and other coatings through its innovative, 35 years of research and development in ceramic technology. Unlike conventional methods that rely on air transfer it also allows for moisture transfer, HPC® Coating differentiates by using vacuum-sealed barrier materials that very effectively prevents heat loss, reduces energy consumption and combats CUI. Its versatility is further demonstrated in its application across a wide temperature range, from ambient to 650°C, making it the most viable option for a multitude of industrial uses.

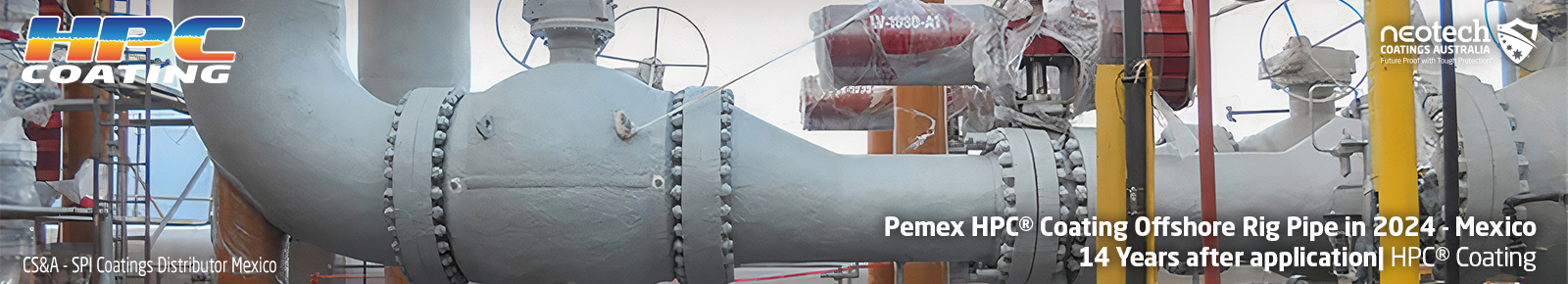

Since 2014 Proven Performance at Pemex Oil, Mexico

The real-world efficacy of HPC® Coating has been proven in some of the most challenging environments. For instance, its application on Mexico’s Pemex Offshore Crude Piping in 2014 showcased its ability to withstand harsh oceanic conditions while providing energy efficiency, reducing maintenance, and preventing corrosion. This level of performance has solidified HPC® Coating‘s reputation as a reliable and effective solution for thermal insulation and corrosion prevention unmatched by any other in the market. Ten years later the coating is holding strong with no maintenance, no shutdown and no corrosion.

Mexico’s Pemex Offshore Crude Piping in 2014 with HPC® Coating’s fresh application with Rust Grip® corrosion prevention and Enamo Grip® protective industrial coating. An average temperature reduction of 55% to a surface below 50°C.

Mexico’s Pemex Offshore Crude Piping in 2024 showcasing HPC® Coating‘s ability to withstand harsh oceanic conditions while providing energy efficiency, reducing maintenance and preventing corrosion and still keeping the average temperature reduction. No deterioration and no drop in performance. Photos: CS&A – SPI Coatings Distributor

Beyond Theory: Field- Tested Success

The partnership between NEOtech Coatings, Australia’s distributor and Superior Products International II, Inc., exemplifies the practical application and success of HPC® Coating. Through collaborations, including with NASA since 1989, which has demonstrated this technology is more than theoretical, steady state lab assumptions from new coatings but a proven solution for slashing energy loss, saving costs, and offering unparalleled durability. As industries in Australia and New Zealand are adopting this advanced and premium technology, the potential for widespread impact and savings will be a game-changer.

Advancing Sustainable Practices

The thermal insulation coatings distributed by NEOtech Coatings have garnered attention for their proven field results and longevity. Unlike traditional insulation methods of jacketing and wraps that have struggled with energy efficiency and corrosion, HPC® Coating provides tangible results, validated by independent engineer testing and celebrated with an EPA award. These advancements are critical as industries look to tackle the challenges of decarbonisation and embrace more sustainable practices.

Personnel Protection Reaches New Standards

Protecting surfaces for personnel is essential for ensuring workplace safety, meeting regulatory compliance, and maintaining operational efficiency. HPC® Coating significantly reduces the risk of accidents and injuries, such as burns or exposure to hazardous materials, thereby preventing unsafe work environments. HPC® Coating can be engineered to a maximum surface temperature of 50°C with high heat underneath ensuring that the surface is safe to touch for much, much longer than 5 seconds. Ultimately, these protective measures are crucial for the overall productivity, safety, and sustainability of an organisation.

Unprecedented Cost Savings

Adopting HPC® Coating offers significant financial and operational advantages, with the potential to save millions annually across facilities, as evidenced by Georgia-Pacific’s returns. The coating not only promotes energy efficiency but also contributes to substantial savings by reducing repair costs, minimising downtime, and contributes directly to the bottom line making any CFO happy. With a conservative estimate showing potential savings of $10 million across 30 plants per annum, and the possibility of exceeding $20 million with multiple units per plant, HPC® Coating emerges as an essential investment for modern industries. Its implementation not only promises remarkable returns but also supports reduced maintenance, less corrosion, and lower carbon emissions, underscoring its comprehensive benefits.

A Sustainable Future with Ceramic Thermal Insulation Coatings

The advancements represented by HPC® Coating multi-ceramic thermal insulation coating, marks a pivotal moment in industrial sustainability efforts. With proven field results in energy savings, corrosion prevention, and safety enhancement, the adoption of this technology will lead to transformative changes across the mining and energy sector. As industries worldwide continue to seek efficient, sustainable solutions, the role of proven, tested and engineered ceramic thermal insulation coatings in shaping an even more energy-efficient future on every level.

Read article