Reduce the solar heat, reduce energy in your warehouse during summer

Here’s some tips to help you reduce energy and increase your warehouse efficiency

Finding ways to reduce energy and in your warehouse during summer can be difficult. Here’s some ways to improve efficiency, reduce your emissions, create employee comfort and protect your assets.

1. Install doors with good insulation

2. Close the door!

3. Upgrade your warehouse lighting

4. Apply proven cool roof coating – 20-50% Reduced Energy (DOE tested)

Air conditioning is costing Australia more than $1.3 billion over the summer months, according to research. Buildings consume 39% of all energy in the economy.

The major areas of total building energy consumption in buildings are:

- 35% – heating, ventilation and air conditioning;

- 11% – lighting;

- 18% – major appliances (water heating, refrigerators and freezers, dryers)

In fact, these account for approximately 64% of total energy use, which makes these systems the best targets for energy savings. The ability to reduce the solar heat load into your building is easily accessible through advanced, tested and proven cool surface coatings which reduce the solar heat and give you a myriad of other benefits.

With some simple steps, you’ll reduce energy use, and also increase your warehouse efficiency.

1. Install doors with good insulation

According to Remax Doors, this may sound obvious, but for many warehouses, insulated doors are not a priority. That’s even though the energy loss through them could be significant when you consider the amount of wall space which they could consume.

Consider all your options and the insulation values of warehouse doors on offer before you make a final decision – the cost savings may be significant.

2. Close the door!

Remax Doors state, one of the biggest loads on an air conditioning is infiltration, defined as the leakage of outdoor air into a conditioned space. Infiltration is even more costly for cold-storage warehouses, walk-in coolers and blast freezers. It can also create an uncomfortable workplace for your employees in the depths of summer and/or winter.

All of this is why insulated doors are necessary for any warehouse trying to maintain a strict interior temperature and lower their energy costs. An open door provides the largest portal for energy loss in any warehouse. To counteract this (since your employees will need to come and go throughout the day), consider opting for doors that are automated, high-speed and easily repaired.

Having doors which are operated by sensors, and which will open and close straight away after personnel have moved through, will cut down significantly on the energy lost when doors are left open for longer than required.

3. Upgrade your warehouse lighting

With lighting, the experts suggest starting with two questions:

1) How much light is necessary in the warehouse?

2) Where is it needed most?

Clearly, automated warehouses (where there is little human activity) require much less lighting than a fully staffed facility. Also, a clerk’s station requires a different kind of lighting than a warehouse floor.

“Think about how warehouses work. Many don’t have people in them,” says Lindsay Audin, president of energy consulting firm Energywiz Inc. “There are robotic warehouses with automated trolleys and robotic forklifts that can operate in the dark.” By adopting more efficient lighting systems, your warehouse can save as much as 50% on your energy bill.

Natural light in warehouses: while skylights are becoming commonplace because of exhaust requirements, the daylight they bring in is an extra benefit. Thermal glass in the skylights can help maintain climate control too. Glazed skylights on north and south facing walls can help provide the optimal diffused daylight needed for a well illuminated warehouse. Diffused daylight is a better light source than lighting as it doesn’t cast the same shadows that overhead lights do and it reaches more of the warehouse.

The benefits don’t stop there: daylight in the workplace is also associated with higher worker production and morale. By matching a photo-control system to well-designed skylights you can have auto adjusting lights to keep your warehouse illuminated as the daylight fades while saving money during the day.

4. Apply proven cool roof coating

Warehouse roofs can be one of the biggest sources of energy inefficiency. Warehouse roofs are notorious for soaking up solar heat and transferring it inside. Even with sarking or foil once the heat is through, you’re hot. An awesome cool roof coating like Super Therm® on a warehouse helps significantly in saving energy amongst other benefits.

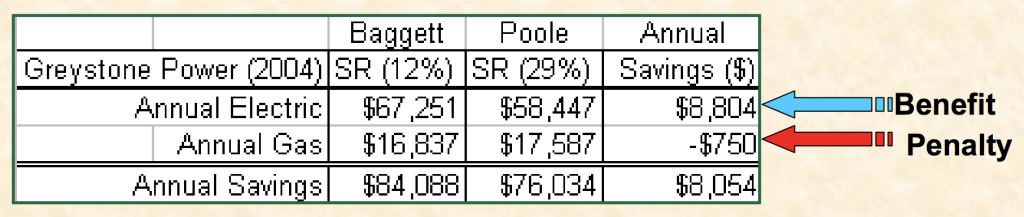

There’s a misleading belief also that the ‘winter penalty‘ is high…it’s not! So just to address this fallacy of the winter penalty up front we’ll utilise a case study by the DOE. With only a 29% solar reflectivity coating on an Elementary School in the USA showed a saving of $8,054 (27%) with a cool roof coating. It even showed the supposed ‘winter penalty‘ was still minor in energy consumption to the cool roof summer advantages. Imagine a coating like Super Therm® that has a 96.1% Total Solar Reflectance (TSR) which will reduce the energy consumption even more!

Warehouse roof can be one of the biggest sources of energy inefficiency, experts say. They are notorious for absorbing solar heat. In fact, the University of South Australia did a study and galvanised and zincalume metals are amongst the worst when it comes to low emissivity. Exposed metals (zincalume & galvanised) are poor at giving off heat (low emissivity) so they become hotter than most other materials having the same TSR. This is between 12 and 20°c hotter than materials having the same TSR. If Super Therm’s emissivity is a very high .91, zincalume is very poor at .20-.30.

Also a study by the University of Melbourne supports this. They found the summer roof temperature profile shows a clear difference of up to approximately 30°c. “As can be seen on the 6th January the control roof (zincalume) reaches 68°c. whilst the coolest roof is 35°c – this supports the suggestion that a “normal” roof is too hot to touch whilst the cool roofs are consistently below 40°c.”

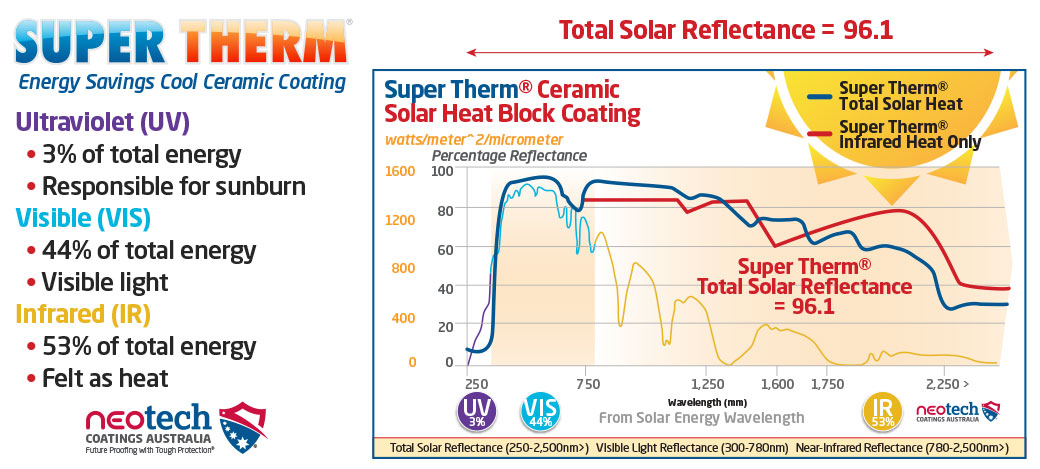

Depending on the warehouse’s purpose, cool roof technologies can cut down on energy costs as we’ve proven with Super Therm®. Super Therm® has been tested by the Department of Energy to block 20-50% energy which improves energy efficiency in these facilities. It’s total solar reflectance of 96.1% is the highest rated cool ceramic coating in Australia and it lasts over 20 years.

Many cool roof systems should promote three vital properties:

- High solar reflectance, which means they absorb less energy from the sun from visual and UV heat which is 47% of the total heat from the sun

- High thermal emittance, which means the coating releases the absorbed radiate heat as energy back out

- Heat load prevention and transfer of infrared heat inside the warehouse which we measure as U-values and Super Therm® with only 0.25mm allows 0.559 W/m2/K through and blocks 96.1% of total solar heat.

Regardless of climate, cool roof technologies are highly beneficial for warehouses with refrigeration storage, which demand consistent year-round cooling energy regardless of their location. One of the other major impacts is also from condensation with the transfer of temperatures from outside to inside.

The basic principles of Super Therm® heat blocking properties are high-performance, thermal solar reflection + low absorptive emissivity + high radiative emissivity + conductive resistance = the incredible thermal solar heat block of Super Therm®.

Some other major benefits of Super Therm® energy saving cool roof coating on galvanised roofs includes:

- Lasts well over 20 years – no cracking, flaking or peeling

- Single coat application – no priming

- No maintenance program required

- Safe, water based and potable water

- Only solar heat block coating developed with NASA

- Fireproof class ‘A’ rating – tested by NASA

- Blocks 50-68% sound

- Prevents thermal contraction and expansion of metal – saves roof replacement

- Saves roofs from future corrosion

- Improves solar panel efficiency and output

- Works even when dirty

- Stops mould and mildew

- Blocks 99.5% infrared heat

- Like your warehouse is under a large, shady tree

Not All Coatings/Paints are Equal

When it comes to protecting your building do you want something of minimum performance (code built) or do you want high performance? The “or equal” equivalency in construction specifications has misled us into thinking that most things of a kind are more or less the same with very little difference. It muddies the waters.

Since many of us don’t have the time, energy or motivation to suss out all the relevant differences we default to over generalisations, because it’s easy. To get the facts about what’s really going on with roof coatings contact NEOtech Coatings before you make a selection. You’ll be glad you did.

References

- Department of Energy: An Assessment of Energy Technologies and Research Opportunities

- Remax Doors

- Facilities Net: Stock Up on Energy Savings

- University of Melbourne: Cool Roofs City of Melbourne Research Report

- Cool Roofs and Heat Reflective Paints – Dr John Pockett, University of South Australia

- Emissivity Table