Yachts for Marine Application Coatings

Entire boat should be aluminium or fiberglass composite. Mainly internal use, for warm climates.

- Seal

- Insulation

- Sound Reduction

- Engine room

- Deck paint

Interior

From water line down, the sea water can be cold with warm humidity inside the cavity of the hull which causes condensation and corrosion inside the hull. Have to pump water out.

While boat is dry docked, you sand all the surfaces of the interior hull to open the pores of the aluminium.

Apply MMG as the primer.

Allow two days to set up so that you can walk on it without damage. Apply HSC at 2 mm dry thickness .25m2 per litre.

Allow to dry – put fans in the hull to move air and make this dry down for two days.

Apply an over coat of Super Therm® at 2.5m2 per litre over the HSC to seal, water proof and it throws off heat.

This will control condensation and possible corrosion development.

Engine room

Noise and heat comes from this room.

Also, if there is a fire that develops, you have 20 minutes to abandon ship before the aluminum melts and she goes down.

Again, prime with MMG at 160 sq.ft per gallon (15.5 sq.m) which is a little thicker than normal but do this for the flooring. The sides can be at 200 sq.ft. Per gallon (18 sq.m).

Apply OMEGA FIRE over the flooring and walls at 320 mils (8 mm) dry thickness. This is to give someone 30 minutes to put out the fire before it begins to get hot enough to start doing damage to the hull Allow to dry for 3 days with fans and warm air to help dry it down. Apply HPC over the wall between the engine room and captain Bedroom (which is usually backed up to the engine room). Can put on ceiling also if noise is coming up into other compartments. This will insulate from heat transfer and noise.

Allow this to dry for a couple of days with fans and warm air to dry down.

Over coat this with SUPER THERM to throw initial heat back into room and brighten the room to see better with the normal lighting.

Over the flooring and OMEGA FIRE, apply a coat of ENAMO GRIP 5000 which is a polyester and withstand the gasoline or solvents spills plus is a 60% solids coating used for flooring to be tough and last. Looks like a car finish.

Air Conditioning ducting

If there is condensation developing throughout the cabins from cold air blowing through the ducting which has become warm and causing condensation, then coat the exterior of the ducting with SUPER THERM. If plastic, sand the surfaces to rough them up so that the SUPER THERM can have a better adhesion. This blocks the ducting from absorbing heat from the ambient close to the exterior hull and allows them to stay cool.

Wheel house and exterior above water line

Sand and rough all the surface for best adhesion.

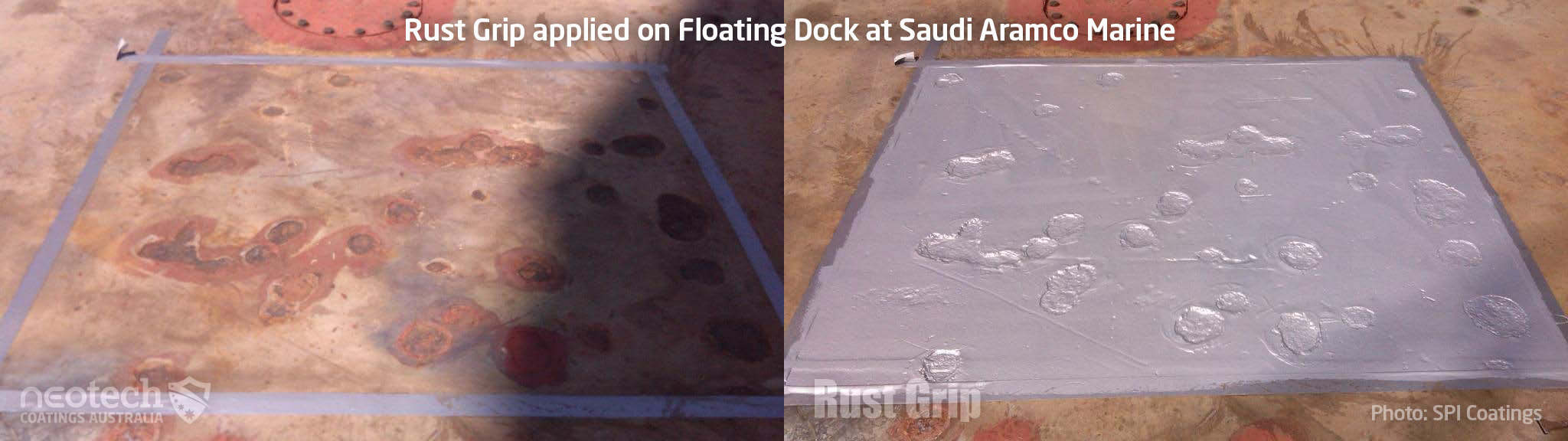

Apply RUST GRIP at 200 sq.ft. Per gallon as the primer.

Apply SUPER THERM at 85 sq.ft per gallon as the insulation factor to face the sun and block the heat load onto the surface of the aluminium.

Allow to fully dry in the sun for a minimum of 2 days.

Over coat the SUPER THERM with a White ENAMO GRIP or polyurethane for gloss, better weathering and toughness. If trim colours of the urethane are dark, no problem.

This system is applied over all areas facing the sun from sides to top and decking. Excepting of top for decking — use ENAMO GRIP 5000.

NOTE: Because SUPER THERM is so white, the ENAMO GRIP 5000 can be tinted down to a beige or dimmed so that it is not blinding. It is best to not use a dark coloured top coat as it will draw heat and hold it. Use a light to medium colour top coat so that you get the benefit of the SUPER THERM not absorbing heat and keeping the decking cool to touch.