Asbestos & Lead Paint Encapsulation

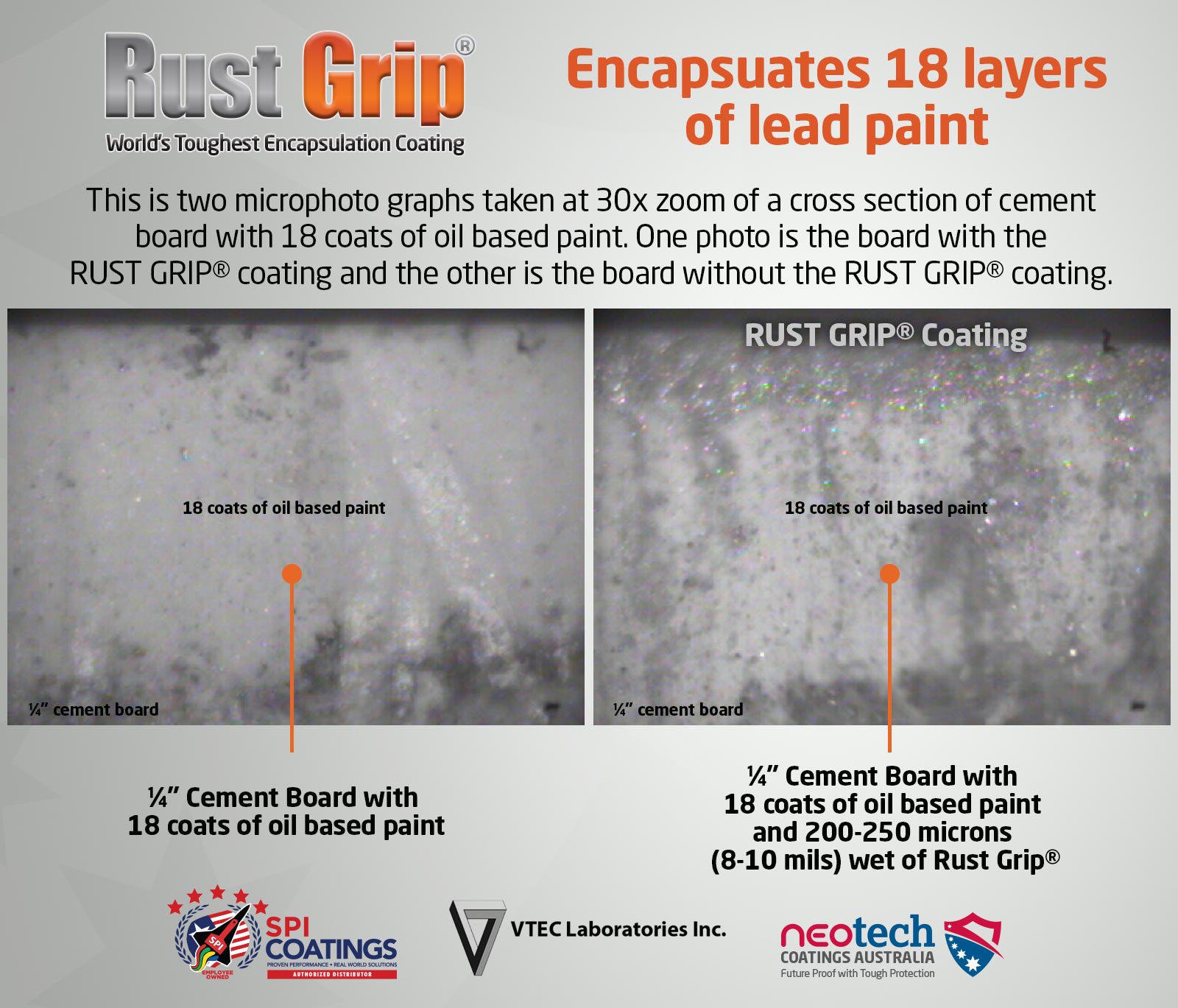

One-Coat Paint System Encapsulates Lead-Based Paint and Eliminates Sandblasting

This specification covers preparation of surfaces and the performance and completion of coating of surfaces to safely abate asbestos and lead base paint.

Why is lead dangerous?

Lead is a naturally-occurring heavy metal. Up until the 1970s, it was used to build pipes, as an additive in paint, and in many other manufacturing and construction scenarios. Lead is dangerous because, in short, it’s toxic to human systems. There’s no way to extract lead from the bloodstream once it enters it, and lead levels can build up over time and cause sickness. The EPA cites children and pregnant women as particularly at risk to lead exposure and health defects, but anyone can suffer from lead poisoning (Source).

Why is asbestos dangerous?

Asbestos is a natural substance that can be found in rocks and soil. The mineral fibre’s durability and resistance to heat allow it to be used in several different ways, like as an insulation component in construction materials and also as non-flammable material. Being exposed to asbestos can have serious, adverse effects on your health. Asbestos exposure can increase your chances of developing lung cancer. Mesothelioma, or cancer of the mesothelial tissue, can develop after being exposed to asbestos. And it can take years for symptoms related to the exposure to appear (Source).

Project Specification for Rust Grip® Encapsulation of Asbestos – pdf

RUST GRIP® encapsulates lead based paint, asbestos or hazardous materials

Use Rust Grip® over porous surfaces to fill, seal, and encapsulate asbestos directly or over the surfaces that have the asbestos fibres encased such as wallboard, metal sheeting, composite materials where Rust Grip® is applied to seal and encapsulate the encasement around the asbestos fibre. Rust Grip® is a high solids (50% by volume) content material.

Rust Grip® heavily coated on the exterior side will seal all the seams, seal the air flow, prevent moisture migration into the fibre and secure the fibres inside the encasement. This is an EPA (Environmental Protection Agency) requirement for encapsulation.

Encapsulation directly to asbestos fibres would require that Rust Grip® be applied at a first coat of 9m2 (100 sq.ft) per gallon to keep the surface wet with the coating to enhance the penetration and absorption of the RUST GRIP into the surface of the asbestos. Using the spring, brush or roller to force the coating into and as deep as possible by using pressure into the fibre is the desired effect. Give the coating one hour to dry and reapply the RUST GRIP in a second coat at 13m2 (130 sq.ft.) per gallon to fill voids, pinholes and secure over the surface of the fibre.

Encapsulation of existing asbestos directly to the surface or over encasements similar to all types of building materials used to build or construct walls or encasements around asbestos fibers, clean surface with power wash 2500 psi and wipe with acetone to dry the surface. Apply two coats at 8 mils wet 4 mils dry (200 sq/ft per gallon). Comply with manufacturer’s recommended technical data for other requirements.

Rust Grip® must be applied very wet over the surface to allow complete absorption of Rust Grip® into the porous fiber of the asbestos. Rust Grip® must be applied in two coats being no more than one hour apart to achieve the dry film thickness over the surface of the building materials used to encase the asbestos fibres and that being 8-10 dry mils (200-250 microns dry).

When applying directly to the fibre, the first coat of Rust Grip® should be applied at 9 sq.m (100 sq.ft.) per gallon to wet out and fill the pores and to penetrate into the fibre surface of the asbestos. Forcing the coating as deeply as possible into the surface must be done to ensure complete encapsulation of the asbestos and to form a bond to the substrate.

Bonding is necessary for the asbestos to remain adhered to the substrate if possible and to seal over the surface when locking down and curing.

The application first seals and stabilizes the surfaces, then produces a durable, long-lasting protective jacket over the asbestos. The use of a “Patch-Test” is recommended.

Rust Grip® can be used over various interior or exterior surfaces including: walls, ceilings, trim, flat transite, rough, porous, textured or irregular surfaces, cementitious surfaces, stucco, wood siding, shingle siding, window frames, windowsills and porch walls, wood overhangs, porch ceilings, and wood trim and posts.

Under normal drying conditions, Rust Grip® develops full strength and chemical resistance properties 10 to 21 days following application.

Lead based paint

Rust Grip® saturates deep into the pores of the substrate.

Rust Grip® is made with low molecular weight solvents that act to provide wetting so that deep penetration can occur.

After it penetrates, Rust Grip® draws moisture from the atmosphere which reacts with the active ingredients of the base component and results in a gassing effect of the molecules.

Molecules expand and swell into all the pores to block out air, gasses, and moisture and to encapsulate the surface.

Rust Grip®

The Ultimate for Encapsulation

Rust Grip® Is a one-part polyurethane coating that combines with atmospheric moisture to cure. Upon curing, Rust Grip® provides a protective coating of superior adhesion, flexibility and abrasion/impact-resistance. It is resistant to chemical solvents and acid splash. Originally designed for metal surfaces, Rust Grip® demonstrates excellent adhesion to wood, concrete, fiberglass and many other substrates. Rust Grip® is designed for the encapsulation of and adherence to tightly-bonded surfaces of lead-based and other toxic paints as well as rusted surfaces and asbestos > Learn More >