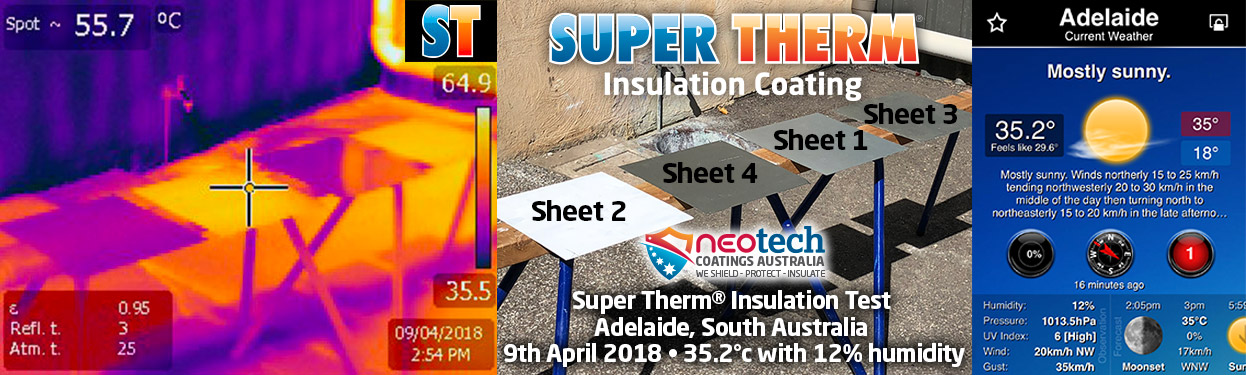

Super Therm® High Performance Solar Heat Block Coating Adelaide Test

Testing conditions

- Temperature coating applied, sunny 32°c humidity 15%

- Temperature measured, sunny 35°c humidity 12%

4 standard sheets of 0.6mm Galvanised metal were used as test sheets for the application of Super Therm®. The test was filmed to show the ease of mixing and application and the results were approximately 21 days following application. This was a field test conduced with:

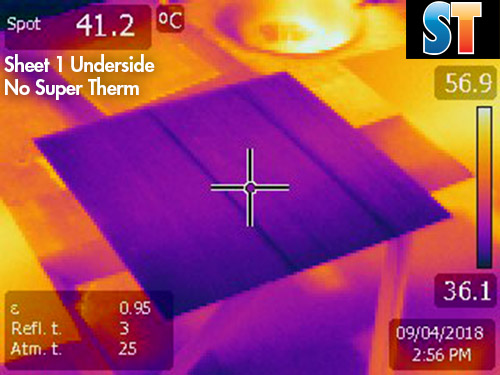

- Uncoated galvanised sheet (300mm x 300mm)

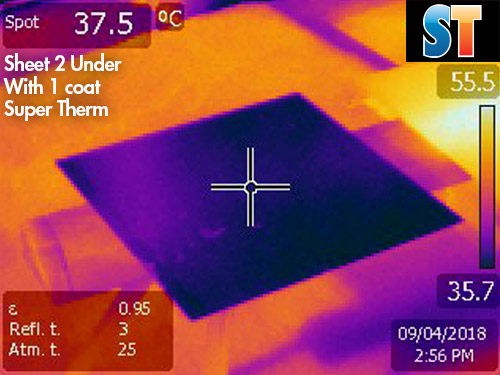

- 1 coat of Super Therm®

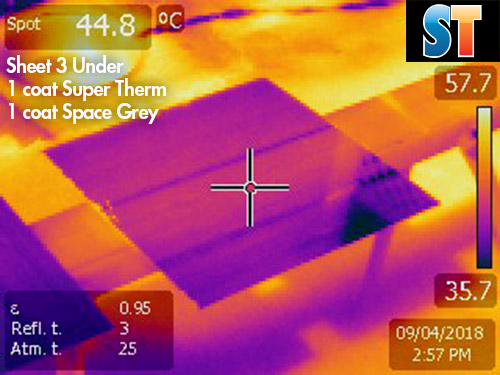

- 1 coat of Super Therm® with 1 coat of dark Space Grey paint

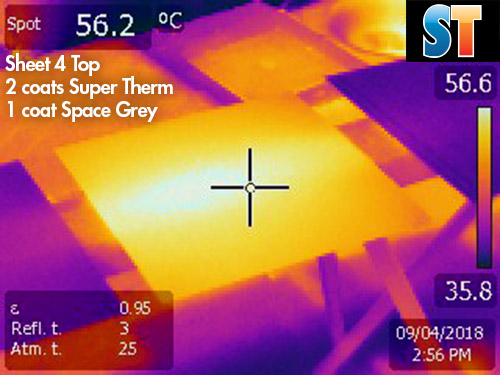

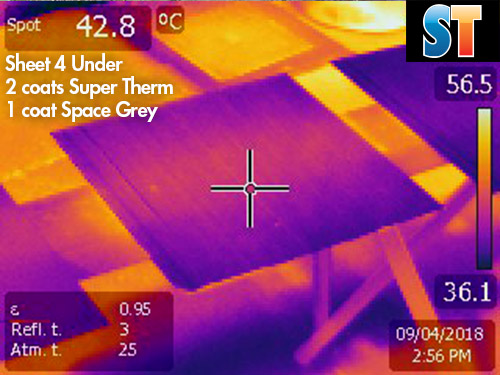

- 2 coats of Super Therm® with 1 coat of dark Space Grey paint

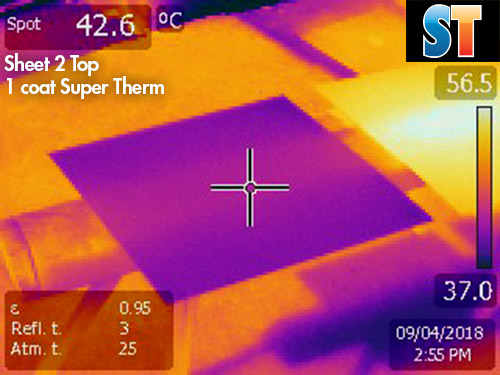

Note: In this test one brush coat of Super Therm® is equivalent to 5-7 mil dry. SPI Coatings the manufacturer always recommend 2 coats by brush to achieve the 10 mil dry thickness. The Sheet 2 reading on top is not fully accurate for this reason, however the efficiency of Super Therm® underneath has achieved just above ambient results.

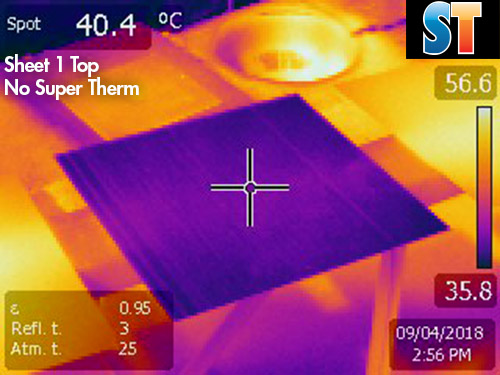

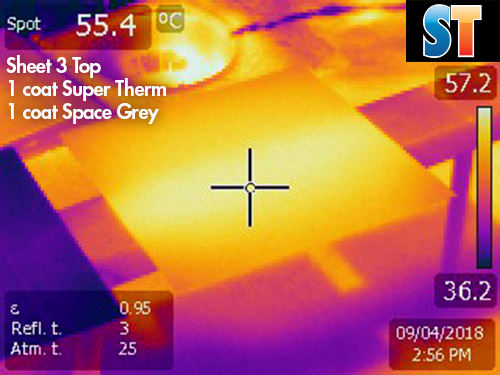

As the Thermo images below show with a spot metre temperature reading the galvanised sheeting showed a 2% increase in temperature under the sheet. All the Super Therm® insulated sheets were between 12% and 23% better underneath with their temperature readings.

A 6° reduction in the thermostat produces a 39% reduction in electricity costs (Con Edison). This test has indicated with a dark roof it would be 13° (22%) difference and improvement with Super Therm®.

Super Therm® (Sheet 2) with just one coat was only 2°c higher on the underside than the ambient temperature of 35°c.

Although we did not test a coat of Space Grey on an uncoated galvansied sheet we estimate even at a conservative 2% increase the underside temperature would be 57° in relation to the 44.8° recorded with Super Therm® which is a 22% difference.

NOTE: We do not recommend applying dark paint over Super Therm® as it blocks the throw off of the radiation heat and blocks emissivity from leaving the surface. We recommend using HSC™ if using dark colours. The Space Grey used in this test was for testing purposes only.

| 35°c Ambient | Sheet 1 | Sheet 2 | Sheet 3 | Sheet 4 |

| Material + coating | Uncoated Galvanised | 1 coat of Super Therm® | 1 coat of Super Therm® and 1 coat of Space Grey | 2 coats of Super Therm® and 1 coat of Space Grey |

| Thermal image on top side of sheet |  |

|

|

|

| Standard image of top side of sheet |  |

|

|

|

| Topside Temperature |

40.4°c | 42.6°c | 55.4°c | 56.2°c |

| Underside Temperature |

41.2°c | 37.5°c | 44.8°c | 42.8°c |

| Ambient 35°C Difference Temperature |

+5.4°c | +2.5°c | +9.8°c | +7.8°c |

| Ambient v Super Therm Difference % | 17% | 5.7% | 27% | 22% |

| Temperature Reduction |

-.8°c | +5.1°c | +10.6°c | +13.4°c |

| % as Degree difference |

-2% | +12% | +19% | +23% |

| Thermal image on under side of sheet |  |

|

|

|

| Standard image on under side of sheet |  |

|

|

|