Insulating Concrete Slabs for Summer and Winter

Super Therm® offers a totally different approach to slab “insulation” by focusing on heat block, not just resistance or mass. Here’s how it helps in both summer and winter:

Super Therm® is a multi-ceramic-based heat block coating designed to stop 96.1% of total solar heat. While traditional insulation slows heat transfer, Super Therm® stops most of it from entering in the first place. When applied correctly, it transforms concrete slabs into passive temperature regulators for both summer and winter.

Key Benefits for Concrete Slabs

Summer:

- Blocks solar radiation from penetrating into the slab

- Prevents heat build-up, reducing internal temperature rise

- Reduces need for air conditioning by keeping surfaces cooler

- Keeps radiant reheat low during evening hours.

Winter:

- In winter, Super Therm® helps retain heat in warmed slabs by reducing emissivity and blocking radiant loss

- A cold slab won’t generate warmth – it needs to first gain and hold heat to be effective

- Enhances underfloor heating efficiency by reducing downward heat flow

- Supports thermal retention, making indoor spaces warmer longer.

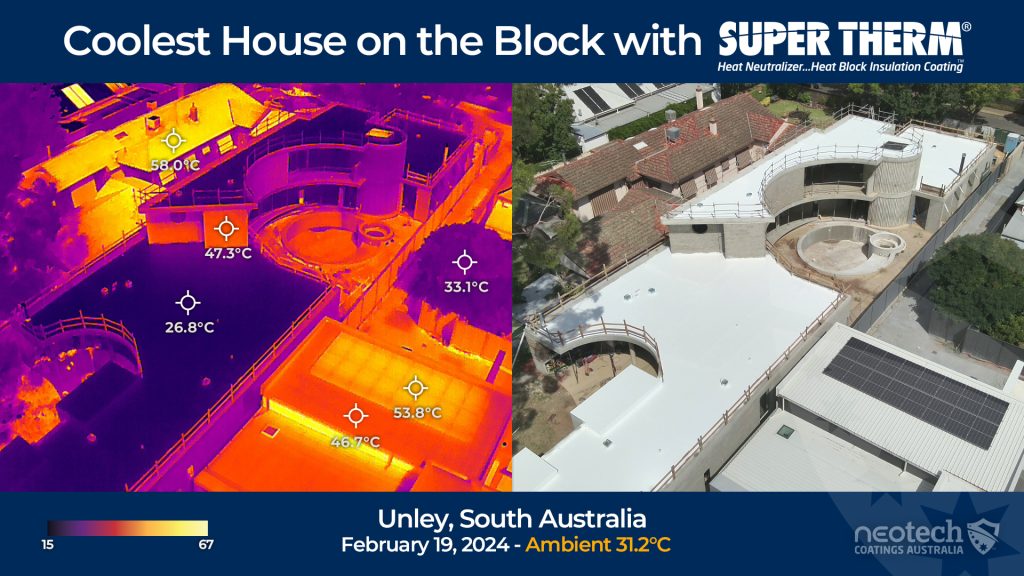

Concrete Home in Unley, South Australia – Super Therm® Case Study

A solid concrete home in Unley, SA, was coated with Super Therm® during peak summer conditions. Here’s what that performance looks like in real-world conditions:

- Ambient temperature: 31°C

- Surface temperature of the Super Therm®-coated concrete: 26°C

- Result:

- Surface temperature was over 7°C cooler than ambient and up to 50% lower than uncoated nearby surfaces — demonstrating a major reduction in heat load

- 7°C cooler than nearby shaded areas under mature trees

- Concrete’s thermal mass remained lower than ambient, proving that Super Therm® actively blocked heat load into the slab

Outcome: The home stayed cooler, more stable inside, and required significantly less energy to maintain comfort—demonstrating how Super Therm® turns high-mass materials like concrete into passive coolers, not heat batteries.

Challenging the Assumptions of Slab Insulation

Many traditional slab insulation strategies rely on a few key assumptions:

- That the slab is fully and properly insulated (underneath and at edges)

- That there is consistent winter solar access

- That ground temperatures are warmer than the internal space

- That thermal mass translates into meaningful thermal performance without delay or loss

In reality, heat loss into cold ground or limited winter sun exposure can make slabs act more like heat sinks than heat batteries. This is where Super Therm® changes the game – by blocking the heat at the surface, before it enters or escapes.

Winter: Keeping Heat In, Not Just Slowing It Down

Traditional slab insulation relies on thermal mass to absorb daytime heat and re-radiate it at night. But this only works if the slab actually gets warm — which, in winter, is far from guaranteed.

Super Therm® doesn’t rely on absorption. It prevents heat loss in the first place.

When applied to interior surfaces (underside of suspended slabs or exposed concrete), Super Therm® blocks radiant heat loss from warm internal air to colder external surfaces. This means:

- Less energy is lost through the slab to the outside or the ground

- Heated slabs (via solar gain or underfloor systems) retain more warmth for longer

- Internal comfort improves without relying solely on heating systems

Key Point: A cold slab doesn’t magically warm the space — but a warm slab, once heated, performs better when radiant heat loss is minimised.

Whether used on its own or in conjunction with underfloor heating or passive solar design, Super Therm® ensures that once heat is inside, it stays there longer — reducing energy demand and maintaining thermal comfort throughout cold cycles.

Application Layouts

1. Podium Slabs / Rooftops

Application Area: Top surface Purpose: Reflects solar heat, prevents slab heating and reduces building heat gain.

2. Exposed Concrete Balconies / Patios / Driveways

Application Area: Top surface Purpose: Prevents solar absorption and radiated heat from transferring into internal spaces or adjacent slab areas.

3. Underside of Suspended Slabs (e.g. car parks, mezzanines)

Application Area: Bottom surface Purpose: Blocks radiant heat loss from internal conditioned space to external environment.

4. Slab-On-Ground with Underfloor Heating

Application Area: Underside (during construction), applied directly to insulation board or structural surface to reflect heat back into the slab and reduce energy loss to the ground. Purpose: Retains heat from underfloor system, reducing downward energy loss.

Complementary Measures

- Use with shading structures to maximise effectiveness

- Combine with vapour barriers for added moisture control

- Ideal for passive solar homes and energy-efficient commercial builds.

Key Comparison Points

| Feature | Traditional Slab Insulation | Super Therm® Coating |

|---|---|---|

| Continuity of Insulation | Must be perfectly continuous to avoid thermal bridging | Seamless ceramic membrane with no joins or gaps |

| Installation Timing | Requires integration during construction | Can be applied before or after construction |

| Heat Load from Sun (Summer) | Concrete absorbs solar heat through top surface | Blocks 96.1% of total solar heat before it enters the slab |

| Heat Loss in Winter | Heat escapes through slab edges/underside to ground | Reflects radiant heat inward, reducing heat loss |

| Thermal Bridging Risk | High if any concrete touches ground/air | None – ceramic layer acts as a complete thermal break |

| Surface Temperatures | Cold in winter, hot in summer | Maintains stable surface temperature year-round |

| Mould/Condensation Risk | High in cold corners (below 12°C surface temp) | Prevents cold spots by reducing heat loss |

| Moisture Sensitivity | EPS, XPS and fibreglass degrade with moisture | 100% moisture-resistant performance |

| Retains Thermal Mass | Often negated by topping insulation | Fully retained – thermal mass stays active inside envelope |

| Labour & Cost | High cost, complex slab detailing | Low-labour, lightweight, simple coating method |

| Real-World Performance | Rely on lab R-values (often drop with heat/moisture) | ASTM tested: Equivalent RSI ~3.3, performance proven globally |

Where Super Therm® Excels:

- Blocks radiant, conductive, and convective heat

- Works across extreme temperatures (-60°C to +120°C)

- Improves U-value performance by up to 80%

- Moisture-proof, mould resistant, non-combustible

- Keeps slabs cooler in summer and warmer in winter

- Ideal for slab-on-ground, suspended slabs, and retrofits

Tested and Proven with ASTM Standards

Independent Lab Testing Confirms It

Super Therm’s performance isn’t just theoretical – it’s been validated with internationally recognised ASTM methods:

- ASTM E1269 – Measures specific heat capacity, confirming Super Therm‘s ability to resist heat absorption

- ASTM E1461-92 – Assesses thermal diffusivity, demonstrating how slowly heat moves through the coating

These tests validate that Super Therm® doesn’t just reflect heat — it actively resists thermal penetration and slows heat transfer across the coated surface. This performance is critical for improving thermal comfort in both summer and winter conditions.

Explore full ASTM test reports and scientific results: Super Therm® Testing and Results

Did You Know?

Two materials with the same R-value can perform very differently under sunlight. Why? Because R-value doesn’t account for radiant heat or thermal diffusivity. Super Therm® does – and that’s what makes the difference in real heat control.

Summary

Concrete slabs can be a major source of heat gain or loss. Super Therm® redefines slab performance by eliminating surface heat load and helping retain internal warmth. With proper application, it turns any slab into an energy-efficient asset, year-round. Where slab performance was once based on hopeful heat storage, Super Therm® shifts the focus to surface control – where real energy savings begin!