Energy Reducing Coatings

With the rising costs of doing business, energy efficiency has never been more important. Coatings from Superior Products International II, Inc., distributed by NEOtech Coatings Australia block heat transfer, in all sorts of places.

Our line of energy reducing solutions include:

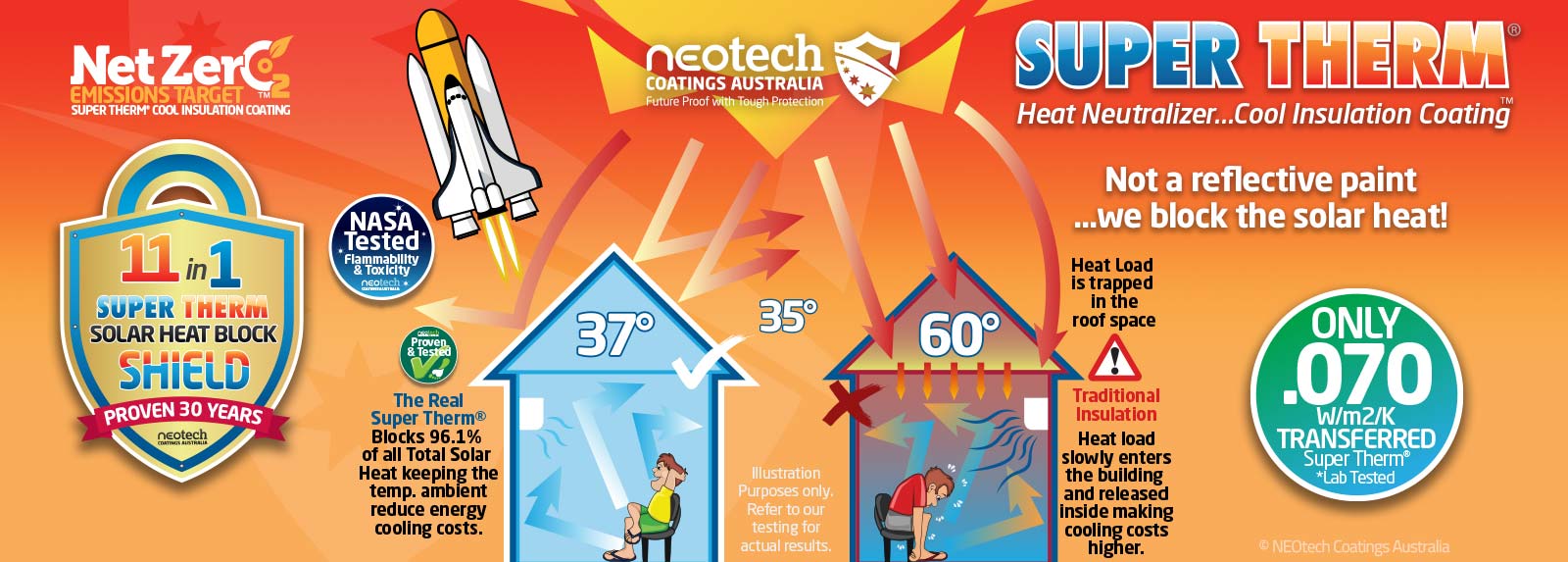

- Super Therm® – Our best selling solar heat block insulation coating

- Sunshield® – A cost efficient solar heat block coating paint

- HSC® – As a base coat/primer or build layers for additional protection

- HPC® – Specially designed for hot pipes and high temperature situations

Reduce Energy with Super Therm® Case Studies

KW reduction = Actual Dollars

39% utility cost reduction

Did you know a 6° reduction in the thermostat produces a 39% reduction in utility costs. Con Edison, NY

Air conditioning is costing Australia more than $1.3 billion over the summer months, according to research. Buildings consume 39% of all energy in the economy.

Super Therm® is Energy Star qualified as a 20 year roof coating. The reality is Super Therm® prevents heat load entering a building. This means that air conditioners don’t need to work as hard to keep the internal environment cooler. This means the less energy consumption is a major cost benefit in power bills.

Super Therm® is used successfully around the world to manage heat load and energy consumption. Here’s some cost benefits examples from around the world along with other case studies in Japan.

Used by Multi-national Organisations and Governments

Super Therm® has been thoroughly tested and proven. It has been used by many multi-national organisations and governments which have applied millions of m2 around the world since it was first released in 1989. It has continued its long lasting, award-winning, proven success for over 30 years and the benefits, environmental rewards and sustainable results are comprehensive.

Reduce Energy with Super Therm® Case Studies

Florida Solar Heat Block Coatings Test – Department of Energy

On February 10th & 11th, 2003 a test was conducted on Super Therm® Solar Heat Block Coating, applied to a residential home roofing system located in Dade County, Florida in accordance with the State of Florida Energy Office / Energy Conservation Assistance Programs Designation: ECAP-CUL-1-99.

As installed, at the time of this testing, the Super Therm® Roof Coating System proved to be an effective Energy Conservation Measure (ECM) that produced a reasonable simple pay back of approximately 2.2 years on this particular project. This would indicate that it’s application could be fundable with Federal and / or State of Florida Energy Grant Dollars where applicable. Note: Results may vary in different conditions and locations.

Denver Solar Heat Block Coatings Test – Department of Energy

On July 19th & 20th,2004 in accordance with the State of Florida Energy Office / Energy Conservation Assistance Programs Designation: ECAP-CUL-1-03 Method for Comparing Utility Loads in Standard Constructed Buildings in Denver, Colorado. The test was over 24 hours between Super Therm® and standard Latex Paint with 2 identical controlled structures. Reports showed it took 30% less energy to heat or cool the building with Super Therm® and moisture levels were reduced. Note: Results may vary in different conditions and locations.

Super Therm® Field Retrofitted Shipping Containers Test (pdf – 1.6mb)

On August 23rd & 24th, 2006 a test was conducted in LaPorte, Texas in accordance with the Florida Energy Conservation Assistance Programs Designation: ECAP-CUL-1-03 Method for Comparing Utility Loads in Structures and Buildings.

Utilising shipping containers, the data indicated that at the time of the test specimen container inside surface conduction related energy loads were reduced approximately 46 to 52% by applying Super Therm® as an Energy Conservation Measure (ECM) to outside surfaces.

- Conduction related energy loads were reduced approximately 46 to 52%

- Internal surface temperatures: 20°C (37°F) Cooler

- Outside Surface Reflectivity: 50% Higher

- Ultraviolet absorption rate: 92% Less

- Internal Moisture levels: 28.5% Dryer