Super Therm® tested by a US Energy Authority

Super Therm® is an innovative and effective energy conservation measure (ECM). SPI Distributors undertook testing with its industry partners associated with the Florida Energy Conservation Assistance Program in 3 different locations.

Summary: On behalf of a US Energy Authority, The State of Florida Energy Office and the United States Environmental Protection Agency, let me thank you for your efforts in developing an affordable product that obviously can be instrumental in Conserving Energy. We hope you will continue to consider Florida as a valuable market for your products. See the full report PDF.

- Florida – July 2003 (pdf / video) – 20-30% Energy reduction

- Denver – February 2004 (pdf / video) – 26-30% Energy reduction

- Texas – August 2006 (pdf / video) – 46-52% Energy reduction

- Georgia-Pacific – Award-winning EPA Energy Savings with HPC

Note: These results may change if in different locations or climates

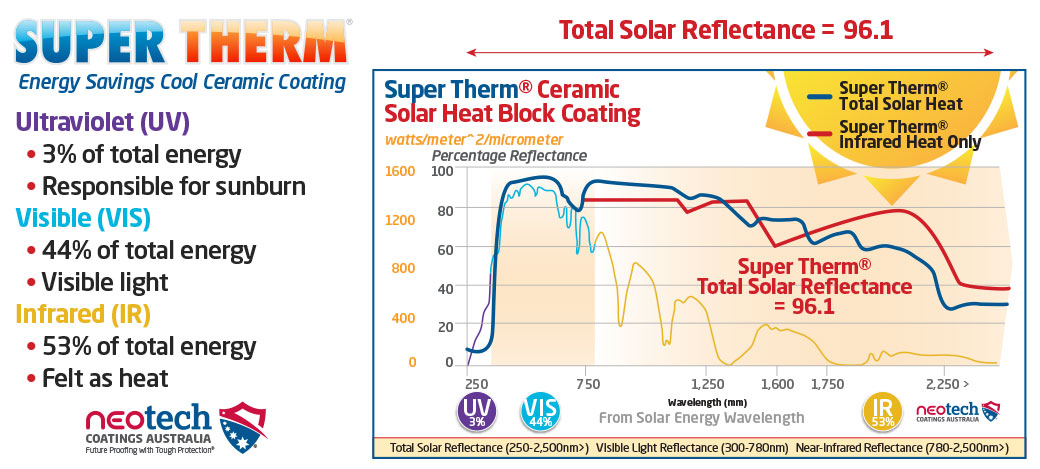

The results of each report were outstanding with regard to Super Therm‘s energy efficiency gains due to reduced BTU’s. Super Therm® has a 99% BTU rating, means it blocks virtually all Infrared heat entering a structure. This is the only product of its kind that makes it a true solar heat block coating, not a reflective paint.

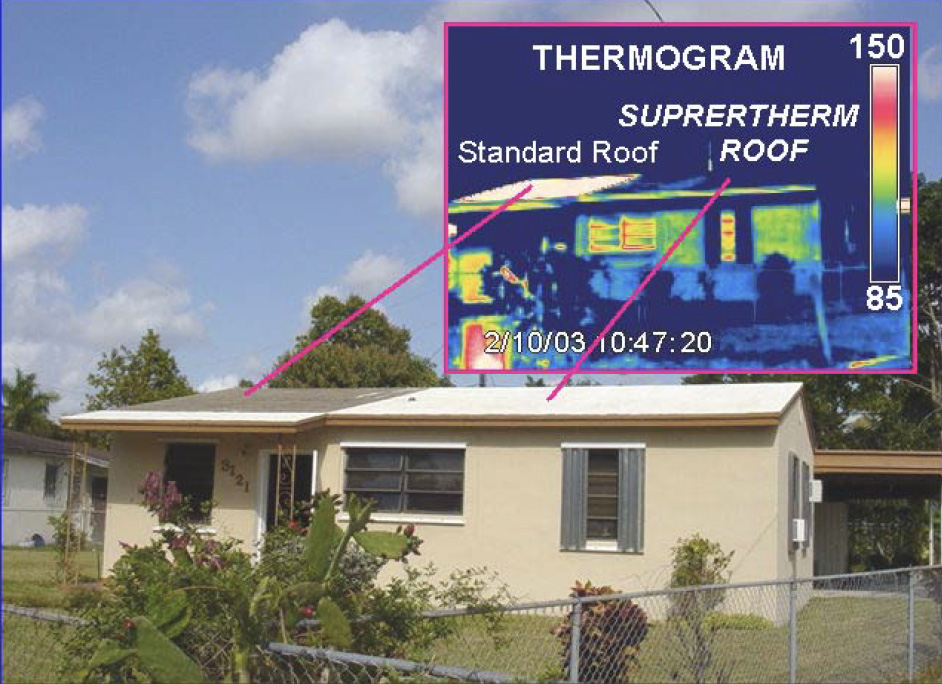

Florida

20-30% Energy reduction

- Pay back of approximately 2.2 years

- Super Therm Solar Heat Block coating: 133,100 BTU’s per hour

- Super Therm® reduced total Roof Solar Gain Loads by 20 to 30%.

On February 10th & 11th, 2003 a test was conducted on Super Therm® Solar Heat Block Coating, applied to a residential home roofing system located in Dade County, Florida in accordance with the State of Florida Energy Office / Energy Conservation Assistance Programs Designation: ECAP-CUL-1-99

Test Method for Comparing Utility Loads in Standard Constructed Buildings.

The objective of this procedure is to determine the actual impact on a facility, after the implementation of a Energy Conservation Retrofit and verify the reduced utility loads, if any, in occupied residential, commercial and government buildings. The focus of this procedure is to provide a comparison to known standards for all parties interested in using energy related products to displaced conventional utility loads. This procedure addresses the energy consumption properties of the equipment and structural envelope tested.

Our testing indicated that your application of Super Therm® reduced total Roof Solar Gain Loads by 20 to 30%. This would qualify as an effective Energy Conservation Measure (ECM) fundable with Federal and State of Florida Energy Grant Dollars where applicable.

Predicated on historically accepted Florida Air Conditioning building component load data (see pdf) and the square footage of the project surveyed, the estimated air conditioning load reduction from the Super Therm® retrofit was approximately 11.09 tons of load per 24 hour period.

- Standard Roof load with no insulation coating: 226,000 BTU’s per hour

- Super Therm Roof load: 93,500 BTU’s per hour

- Reduction from Super Therm solar heat block coating: 133,100 BTU’s per hour

- Reduced environmental impact 66 pounds of power plant emissions per hour

As installed, at the time of this testing, the Super Therm® Roof Coating System proved to be an effective Energy Conservation Measure (ECM) that produced a reasonable simple pay back of approximately 2.2 years on this particular project. This would indicate that it’s application could be fundable with Federal and / or State of Florida Energy Grant Dollars where applicable.

On behalf of a USA Energy Authority, The State of Florida Energy Office and the United States Environmental Protection Agency, let me thank you for your efforts in developing an affordable product that obviously can be instrumental in Conserving Energy. We hope you will continue to consider Florida as a valuable market for your products.

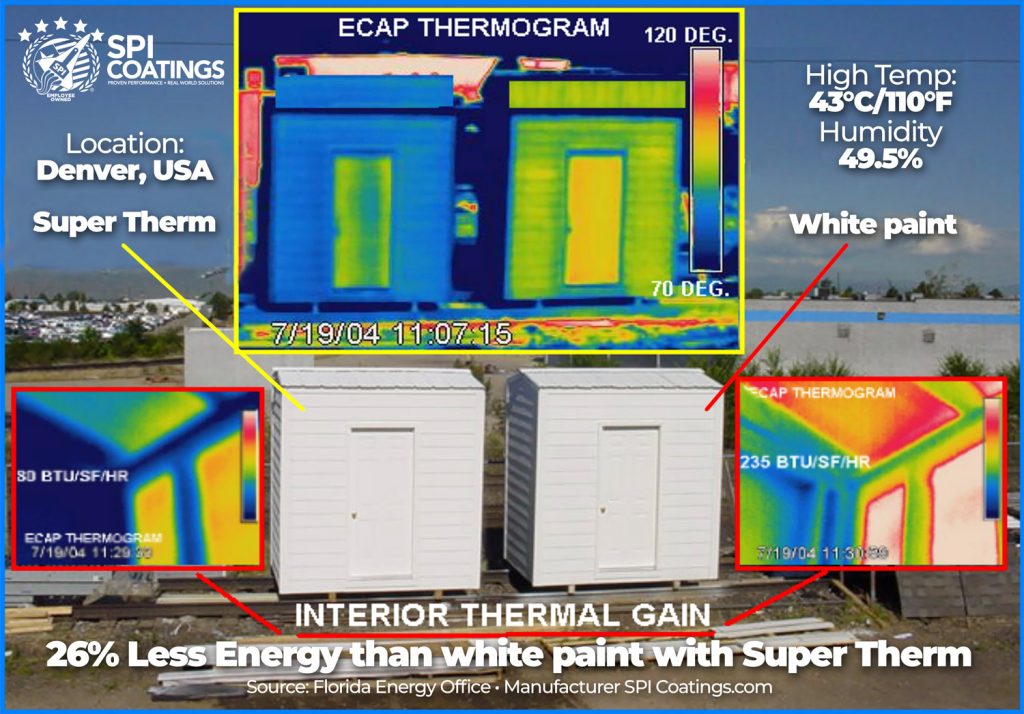

Denver

26-30% Energy reduction

- A 26 to 30% overall increase in energy efficiency

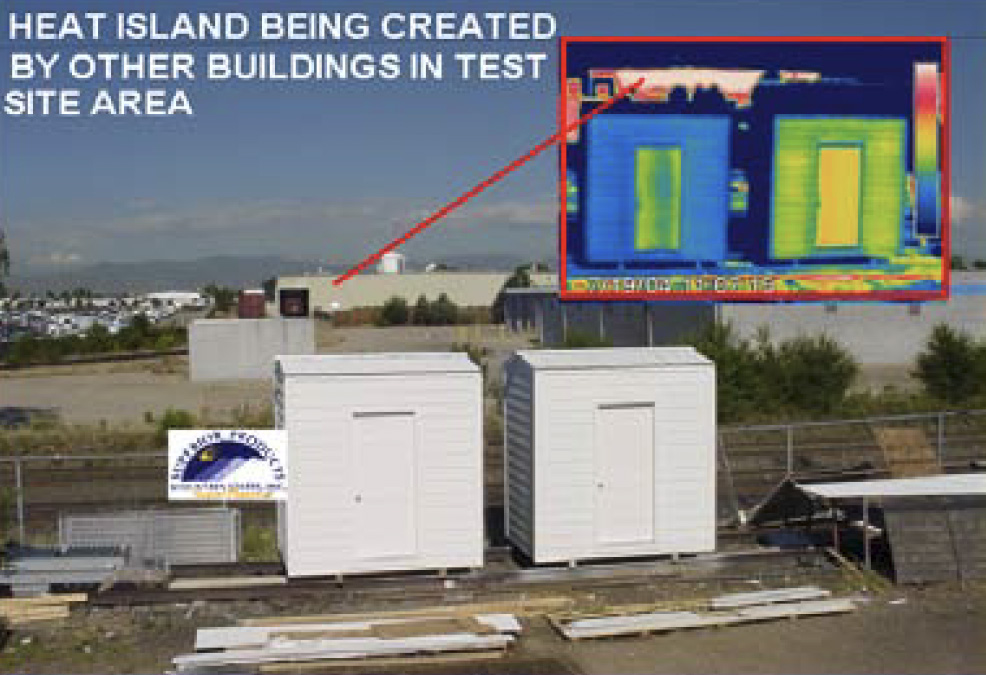

- Reduced Heat Island Effects taking place in most urban areas

On July 19th & 20th, 2004 in accordance with the State of Florida Energy Office / Energy Conservation Assistance Programs Designation: ECAP-CUL-1-03 Method for Comparing Utility Loads in Standard Constructed Buildings in Denver, Colorado.

The objective of this analysis is to determine the impact of the “As Built Conditions and As Installed Components / Equipment” on the utility loads in occupied residential, commercial and government buildings. The focus of this procedure is to provide a comparison to known standards for all parties interested in using alternative energy devices to displaced conventional utility loads. This report reflects the performance characteristics of Super Therm®, as applied to the test facilities external surfaces, as a possible passive Energy Conservation Measure (ECM) to reduce internal Energy Loads and reduce the Heat Island Effects caused by roofing systems in urban areas.

The location of the test specimens was adequate. Both buildings were of standard construction consisting of wood framing, standard OSB wall and roof sheeting’s with a standard galvanised metal roof covering and James Hardey Board external wall coverings. The calculated R-Value of the uncoated existing materials was found to be approximately an R-2.45. The only difference between the two buildings consisting of approximately 48 square feet of control zone area was the external protective coatings.

One of the buildings was coated with a standard white latex paint while the other buildings roof and all external surfaces, including the front door had been coated with Super Therm®. As noted and some of the test results this report the differences created by Super Therm® concerning load reductions produced by thermal conduction, convection and absorption were significant. Additionally, significant reductions in moisture infiltration were also noted.

Our survey indicated that the test specimen’s building envelope related energy loads were reduced approximately 26 to 30% by the use of this particular Energy Conservation Measure (ECM). This was accomplished with no negative effect on the existing buildings Architectural Aesthetics.

Our Energy Flow analysis using a simulated water flow rate of approximately 6.5 gallons per minute indicated that the standard constructed building would require a minimum of 1,037 BTU’s of heating or cooling energy per square foot to maintain a minimal comfort level.

In retrospect, the building coated with Super Therm® reduced these loads to 766 BTU’s of heating or cooling energy per square foot to maintain the same minimal comfort level. This relates to a 26 to 30% overall increase in energy efficiency depending on the percentage of direct solar gain.

While on that subject, our office feels that particularly when addressing external building thermal loads, your product could significantly reduce the Heat Island Effects taking place in most urban areas. The photo and Thermogram below clearly show the benefits provided by your product in this arena.

This is the second time we have had the pleasure to test your product, it is rare that a single product will show such Repeatable Results in two totally different environments, South Florida and Denver Colorado, a true testimonial to your products ENERGY STAR rating.

Data:

- R-Value of the uncoated existing materials was found to be approximately an R-2.45

- The only difference between the two buildings consisting of approximately 4.4m2 (48f2) of control zone area was the Super Therm® external protective coatings

- Highest ambient temperature 43°C/110°F and Humidity 49.5%

- One of the buildings was coated with a standard white latex paint

- Other buildings roof and all external surfaces, including the front door had been coated with egg shell white Super Therm®

- The differences created by the Super Therm® product concerning load reductions produced by thermal conduction, convection and absorption were significant

- Significant reductions in moisture infiltration

- Standard white constructed building would require a minimum of 1,037 BTU’s

- Super Therm® product reduce these loads to 766 BTU’s of heating or cooling energy per f2

- This relates to a 26 to 30% overall increase in energy efficiency depending on the percentage of direct solar gain.

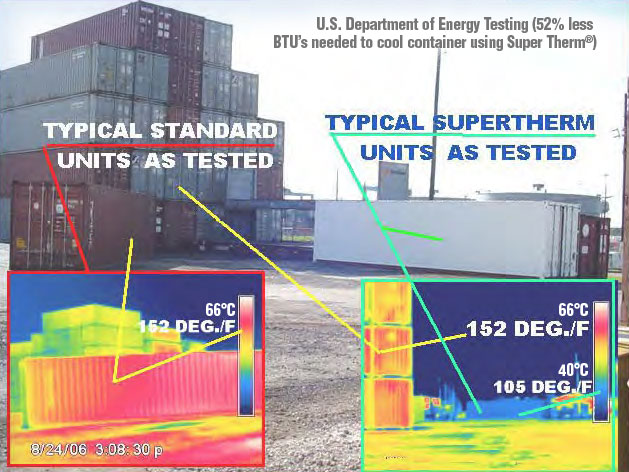

Texas

46-52% Energy reduction

Shipping Containers

- Conduction related energy loads were reduced approximately 46 to 52%

- Internal surface temperatures: 20°C (37°F) Cooler

- Outside Surface Reflectivity: 50% Higher

- Ultraviolet absorption rate: 92% Less

- Internal Moisture levels: 28.5% Dryer

On August 23rd & 24th, 2006 a test was conducted in LaPorte, Texas in accordance with the Florida Energy Conservation Assistance Programs Designation: ECAP-CUL-1-03 Method for Comparing Utility Loads in Structures and Buildings.

The objective of this analysis is to determine the impact of the “As Built Conditions and As Installed Components / Equipment” on the energy producing loads on occupied residential, commercial, government building and other structures. The focus of this procedure is to provide a comparison to known standards for all parties interested in using alternative and conventional conservation products and devices to displaced energy loads. This report reflects the performance characteristics of Super Therm®, as applied to the structures external surfaces, as a possible passive Energy Conservation Measure (ECM) to reduce internal Energy Loads and reduce the Heat Island Effects caused by exposed surfaces in urban areas.

Our data indicated that at the time of this survey the test specimen container inside surface conduction related energy loads were reduced approximately 46 to 52% by applying Super Therm® as an Energy Conservation Measure (ECM) to outside surfaces.

Average site weather conditions during the analysis period were as follows:

- High Temperature 36°C (97°F).

- Low Temperature 23°C (74°F)

- Average Wind Speed 2-4.7 knots (3 to 5.5 MPH)

- Average UV intensity 99 A+B

Outcomes:

- Inside container ambient temperature: 12°C (22°F) Cooler

- Thermal conductance to outside environment: 50% Less

- External surface temperature: 26°C (47°F) Cooler

- Internal surface temperatures: 20°C (37°F) Cooler

- Outside Surface Reflectivity: 50% Higher

- Ultraviolet absorption rate: 92% Less

- Internal Moisture levels: 28.5% Dryer

Award-winning Energy Savings with HPC

Georgia Pacific (part of Koch Industries – equity value of $13.21 billion) received a New Technology Award at the ENERGY ENGINEERS CONFERENCE in Orlando Florida October 25, 2023 for using thick HPC® Ceramics Thermal Insulation Coating at one of their plants after removing the standard insulation and finding that the coating could have an ROI of less than a year after replacing the standard insulation. Standard insulation never offers ROI.

The award was given out by ENERGY STAR run by the US EPA after studying the savings numbers and engineering report. This shows in real world use and measured by the engineering staff how effective thick C-TIC can prevent energy loss off the surface of tanks and pipes.

“We are pleased to announce two of our mills have been awarded the 2023 ENERGY STAR® by the U.S. Environmental Protection Agency for superior energy performance. Both our Leaf River cellulose mill in New Augusta, Mississippi, and pulp and paper mill in Brewton, Alabama, have been certified for three years indicating these two facilities are first quartile energy efficient.” Georgia Pacific Facebook