Reducing Embodied Carbon with Super Therm®: The Game-Changer for Residential Retrofitting

Embodied Carbon’s Impacts

In the global fight against climate change, much attention has been given to reducing operational carbon—the emissions from heating, cooling, and powering buildings. However, embodied carbon represents a hidden but critical component of our built environment’s carbon footprint. Embodied carbon refers to the total greenhouse gas emissions (GHG) produced during the extraction, manufacturing, transportation, and installation of building materials, as well as their disposal at the end of life.

As the world moves towards a net-zero future, reducing embodied carbon is just as important as improving operational efficiency. It is estimated that embodied carbon will account for nearly 50% of total new construction emissions between now and 2050. That means even before a building becomes operational, its environmental impact has already been locked in.

The Science of Heat and Super Therm’s Protective Capabilities

Heat transfer occurs through three primary mechanisms: conduction, convection, and radiation. Traditional insulation materials primarily focus on conduction, but they fail to address the full spectrum of heat transfer. Super Therm® is engineered to block all three heat transfer methods, making it a superior thermal insulation solution. With the use of 4 specific ceramic compounds and a tough acrylic urethane binding this is the best performing thermal insulation coating on the market for total solar heat.

Super Therm® is specifically designed to block and reflect the three key forms of radiant heat:

- Infrared (IR) Radiation – 53% of solar heat – The primary source of radiant heat transfer into buildings and built materials.

- Ultraviolet (UV) Radiation – 3% of solar heat – Causes material degradation and increases heat absorption.

- Visible Light (Vis) – 44% of solar heat – The visual colour spectrum that contributes to solar heat gain based on solar absorption due to surface colour.

Through extensive laboratory and field testing, Super Therm® has demonstrated its heat-blocking capabilities, outperforming conventional insulation materials. Independent studies, including those conducted by the Florida Energy Office (FEO), showed that Super Therm® is a game-changer for reducing heat load, improving energy efficiency, and minimising embodied carbon. Three trials showed 20-52% energy savings!

Super Therm® and the Passive House Standard

Super Therm® aligns with Passive House (Passivhaus) principles, which focus on ultra-low energy buildings that require minimal heating or cooling. Five key design principles and performance criteria for Passivhaus standards:

1. Airtightness ✅

2. High-Performance Insulation ✅

3. Thermal Bridge-Free Design ✅

4. Energy-Efficient Ventilation with Heat Recovery

5. High-Performance Windows and Doors ✅

Passivhaus standards in Australia emphasise energy efficiency, thermal comfort, and airtightness. Super Therm‘s comprehensive suite of benefits – including:

- superior thermal insulation

- high permeability

- exceptional fire resistance

- energy savings

- condensation control

- mould resistance

- acoustic dampening and

- durability and longevity

- green, safe and sustainable solution – align with these stringent requirements.

One of the key components of Passive House design is U-values (pdf), which measure a material’s thermal transmittance. Super Therm® effectively contributes to a low U-value, meaning it significantly reduces heat transfer through building envelopes. This is particularly important for retrofitting older homes, as it enhances thermal performance without requiring excessive insulation materials. See the U-value data on the Passivhaus page.

Its integration into building designs facilitates the creation of structures that are not only compliant with Passivhaus criteria but also exceed traditional building performance metrics.

Top 5 Strengths of Super Therm® for Residential Retrofitting

1. Heat Block Thermal Insulation

Super Therm® is designed to block 96.1% of total solar heat, preventing heat load from entering a building. This makes it a superior solution to protecting homes working with conventional insulation. It’s applied to the none-protected surfaces at the external envelope, roofs and walls where we block the heat outright.

2. Fire Resistance

Super Therm® is highly fire-resistant and has been tested to ASTM E-84 Class A standards, including by NASA, meaning it provides an added layer of fire resistance for buildings. This enhances the safety of residential structures while offering long-term durability. It was also approved in Sheffield Council, Tasmania, with a low BAL rating of 2 on a shipping container home. See all the fire testing!

3. Longevity – Over 20 Years of Performance

Unlike traditional insulation, which deteriorates over time, Super Therm® has a proven lifespan of over 20 years with minimal maintenance. In fact we’re at a 35+ year test in Kansas started in 1989. No peeling, flaking and lifting with a performance drop of 15-20% in 35 years. This durability ensures long-term energy savings and fewer replacements, reducing embodied carbon over a building’s life cycle and landfill from bulk insulation materials.

4. Energy Savings

By significantly reducing heat load, Super Therm® lowers the demand for air conditioning, resulting in energy savings between 20-52% depending on each location. This directly translates to lower electricity bills and reduced carbon emissions. In a study conducted by the Florida Energy Office, Super Therm® was applied to a test building’s exterior surfaces to evaluate its impact on energy efficiency. The results demonstrated a 26% to 30% reduction in energy loads, highlighting the coating’s effectiveness in enhancing energy efficiency. Similarly, a project involving Super Therm® application on mobile phone containers resulted in a 52% decrease in kilowatt usage, leading to significant cost savings on utility bills.

5. Personal Safety

Super Therm® helps regulate indoor temperatures, reducing the risks associated with extreme heat exposure. This is particularly important in regions prone to heatwaves, where excessive indoor temperatures can pose health risks. By blocking 96.1% of total solar heat, Super Therm® significantly reduces indoor temperatures, preventing excessive heat buildup and lowering humidity levels. This creates a cooler and more comfortable environment, reducing the risks of heat stress, dehydration, and respiratory issues caused by high humidity. By minimising indoor heat exposure, Super Therm® alleviates pressure on the healthcare system by decreasing heat-related illnesses and hospital admissions, especially during extreme heat events. Additionally, the coating prevents surface overheating, reducing the risk of burns from hot metal roofs, playground equipment, and vehicle exteriors, making environments safer for families, pets, and workers.

Super Therm® also plays a crucial role in energy cost reduction and sustainable heat protection. By reflecting UV, visible, and infrared radiation, it lowers cooling demand, resulting in up to 20-52% energy savings. This is particularly beneficial for vulnerable populations who struggle with rising energy costs. In urban environments, Super Therm® helps mitigate the Urban Heat Island Effect, creating cooler cities and reducing heat-related risks. It is also an ideal solution for refuge rooms, offering a safe, energy-efficient space during extreme heatwaves. By integrating Super Therm®, businesses, households, and governments can enhance public safety, lower energy costs, and build climate-resilient environments.

Super Therm® in Action: Case Studies

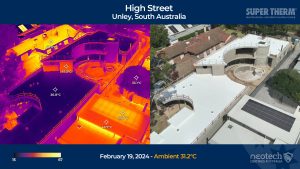

City of Adelaide Cool Roof Trial: Super Therm® Proven to Reduce Heat Load

114% temperature reduction and no urban heat island

In the City of Adelaide Cool Roof Trial (2022-2023), managed and measured by the University of Adelaide, Super Therm® was applied to a roof for the South Australian Netball Association in the parklands to assess its impact on heat absorption and reducing urban heat. Before application, the roof reached 53°C on a 25°C day, significantly contributing to internal heat gain. After applying Super Therm®, the same roof recorded just 23°C on a 27°C day, demonstrating a substantial reduction in heat absorption. The Super Therm® coating resulted in a 114.3% reduction in the temperature increase above ambient, effectively bringing the roof surface temperature near ambient levels. This highlights its exceptional performance in blocking heat absorption.

The trial confirmed Super Therm’s ability to lower energy consumption, improve occupant comfort, and reduce the urban heat island effect, aligning with Adelaide’s Integrated Climate Strategy 2030. City of Adelaide refuse to release the report. Contact them for more information.

Reflective Coating Enhances Passenger Comfort and Reduces Energy Consumption at Las Vegas Airport

Metal air bridges same as ambient and just 3 minutes to cool down

Harry Reid International Airport in Las Vegas had Super Therm® applied to over 100 passenger boarding bridges to combat extreme desert heat. With over 58 million passengers a year, the air bridges are essentially moveable shipping containers. After testing with all competitors, Super Therm® was shown to be 6°C cooler than any other coating keeping the surface near ambient. Prior to the application, external surface temperatures of these metal bridges could exceed 93°C (200°F) during summer, significantly increasing cooling demands and running air conditioners for 20 minutes before a plane landed.

Post-application, the bridges maintained temperatures only a few degrees above ambient indicating 40-50°C differences, resulting in faster cooling times down to 3 minutes and reduced energy consumption. This initiative not only improved passenger comfort but also decreased wear on preconditioned air units, aligning with the airport’s sustainability goals. See the project!

Florida Energy Study: Super Therm® Delivers 20-30% Energy Reduction & Rapid Payback in 2.2 years

FEO found 11.09-ton reduction in BTUs per hour with 2.2 years payback

A 2003 study in Dade County, Florida, conducted under State of Florida Energy Office testing protocols, confirmed Super Therm® reduced Roof Solar Gain Loads by 20-30%, significantly lowering air conditioning demand. The study found an 11.09-ton reduction in cooling load per day, equating to 133,100 BTU/hour less heat absorption. This resulted in 66 pounds fewer power plant emissions per hour, contributing to both energy savings and environmental benefits.

The Super Therm® coated roof carried a 93,500 BTU/hour load, compared to 226,000 BTU/hour on an uncoated roof, demonstrating its high heat-blocking efficiency. With a payback of 2.2 years, it qualifies as an Energy Conservation Measure (ECM) eligible for Federal and State of Florida Energy Grant funding. Supported by the Florida Energy Office (FEO), USA Energy Authority, and EPA, Super Therm® proves to be a cost-effective, high-impact solution for residential, commercial, and government energy savings. See the report! Results will vary in different locations.

Perceived Challenges of Super Therm® in Retrofitting

In keeping it real, while Super Therm® provides significant benefits, it is important to consider some limitations that homeowners and builders should be aware of:

Too Far Ahead for the NCC Standards in Australia

The National Construction Code (NCC) of Australia primarily assesses thermal performance based on R-values, which measure a material’s resistance to heat flow. Traditional insulation materials are rated using this metric. However, Super Therm® operates differently by reflecting and blocking solar heat rather than resisting heat flow through thickness. This innovative approach doesn’t align with the conventional R-value assessment method utilised by the code. However Super Therm has been tested to ASTM C236 – Standard Test Method for Steady-State Thermal Performance of Building Assemblies by Means of a Guarded Hot Box. See the full test results.

Consequently, while Super Therm® offers significant energy efficiency benefits, its performance characteristics don’t fit within the NCC’s traditional insulation criteria. This discrepancy means that Super Therm® may not be recognised under current NCC standards, despite its effectiveness in reducing heat gain and energy consumption. It’s essential to consider these differences when evaluating compliance and performance within the framework of Australian building regulations.

Surface Preparation and Application

Super Therm® requires a pressure clean of the surface for optimal adhesion and performance. Surfaces need to be clean, dry, and free of contaminants before application. If not properly applied, performance may be compromised. Correct application, its that simple! Dry film thickness is only 0.25mm (250 microns) and generally no primer or topcoat is needed. The best performing, thinest heat block coating in the world that can be tinted or overcoated.

Not a Complete Replacement for Traditional Insulation in Many Climates

In extremely cold climates, Super Therm® primarily helps with radiant heat blocking rather than thermal mass insulation. While it reduces heat gain exceptionally well from the sun in warm to hot climates, additional insulation is still be needed in regions with longer winters. The long believed Winter Fallacy doesn’t really exist. In fact the cooling benefits of Super Therm® over summer far outweighs the losses in winter which was raised by the City of Adelaide Cool Roof Trial.

Cost vs. Traditional Insulation

Initial costs for product and application may be higher than some conventional insulation methods. However, long-term energy savings and durability often offset the upfront investment. Particularly if you can get a return within 3 years. As Super Therm® is a high performing insulation coating, the ability to perform that task is challenging. It takes the best formulation and properties to block heat, resist fire, reduce acoustics, remain permeable, no mould and last over 20 years. In the meantime traditional insulation performance drops considerable and needs to be put in landfill. With regard to overall performance, Super Therm® is outside facing the battle of heat, elements and durability testing, traditional insulation would immediately fail.

Super Therm® is Imported

The cost of shipping on embodied carbon varies depending on the distance, weight of the materials being transported, mode of transport (e.g., ship, truck, train), and the specific carbon emission factors used, but generally represents a greater portion of a material’s overall embodied carbon footprint. However the long term carbon savings measures are the primary benefit of the coatings sustainability, in fact its primary goal is reduced energy loads and reduce carbon is to cool. The product is manufactured in the USA and freighted across to Australia.

Super Therm® has little impact on landfill while reducing emissions along with the constant carbon reduction from reduced energy demands, fully offset the transportation and very minimal production expenses.

Super Therm®: Proven, Tested, and Unstoppable – Debunking the Myths Once and For All

The Super Therm® naysayers have always been proven wrong, and the facts speak for themselves. Unlike conventional insulation materials that rely on thickness and R-values at low temperatures, Super Therm® is a multi-ceramic heat-block coating designed to prevent heat load from ever entering a surface—a fundamentally different and superior method of thermal protection.

Why the Critics Are Wrong

- Government & Lab Tested – Super Therm® has been rigorously tested by the Florida Energy Office, the Japanese Construction Material Testing Center, NASA-affiliated labs, and independent verification ASTM worldwide standards including Thermal Diffusivity. The results? Consistent and large energy savings and heat-blocking performance.

- Field-Proven for Over 35 Years – Super Therm® isn’t just lab-tested; it has a track record of real-world success in some of the harshest environments—industrial plants, commercial buildings, military applications, and extreme climate zones…along with houses.

- Not Traditional Insulation—It’s Smarter – Unlike bulk insulation that absorbs and eventually releases heat, Super Therm® works by reflecting and repelling 96.1% of total solar heat, stopping heat before it becomes a bigger problem. Most buildings absorb heat!

- Proven in Extreme Conditions – Whether it’s in the Middle East’s scorching sun, the Las Vegas airport jet bridges, or high-humidity environments like Japan, Super Therm® and Outback Australia has outperformed traditional insulation solutions repeatedly.

- Endorsed by Industry Experts – If this technology didn’t work, NASA wouldn’t have worked with SPI Coatings to develop it, the US Department of Energy wouldn’t have validated it, and major industries worldwide wouldn’t be using it for energy savings. It was so good the City of Adelaide won’t release the Super Therm® Cool Roof Trial Report.

The Verdict? Super Therm® Works—Every Time

The criticisms of Super Therm® are outdated, misinformed, or based on a lack of understanding of radiant heat-blocking technology. Every time a skeptic has tested it, they’ve been forced to change their stance.

This isn’t just insulation—it’s advanced heat-blocking technology that saves energy, cuts costs, and reduces heat load like nothing else on the market.

For more insights into independent discussions on heat-reflective coatings, refer to White Paint Fallacy and Debunked Media. You can also visit NEOtech Coatings for further product details and real-world applications.

The Future of Low-Carbon Homes with Super Therm®

The residential sector is a key driver of global carbon emissions, with embodied carbon in construction materials and ongoing energy use contributing significantly to climate change. Super Therm® is a proven, high-performance heat-blocking coating that directly reduces both embodied and operational carbon, making it an essential tool for building a sustainable future.

By eliminating the need for thick, resource-intensive insulation and significantly lowering energy demand, Super Therm® slashes carbon emissions at every stage of a building’s lifecycle. Its long-lasting durability of 20+ years further reduces the need for replacement materials, cutting waste and conserving resources.

Retrofitting homes with Super Therm® transforms buildings into low-carbon, energy-efficient spaces, reducing air conditioning reliance by up to 20-52%, cutting energy costs, and lowering strain on power grids. By making all surfaces near ambient, Super Therm® mitigates urban heat island effects, protects vulnerable populations, and supports net-zero housing initiatives.

As governments and industries push for carbon neutrality, adopting Super Therm® is a cost-effective, scalable solution that empowers homeowners to make an immediate, measurable impact in the fight against climate change.