Thermal Diffusivity: The Overlooked Key to Future-Ready Passive Building Design

Passivhaus, NCC, BASIX, and global high-performance standards have radically transformed energy-efficient design. But a critical thermal property remains underused: thermal diffusivity. This guide reveals how this missing metric can bridge the gap between compliance and climate resilience — and why it’s the next evolution in advanced building physics.

Passivhaus buildings are designed to resist heat flow and minimise energy loss through U-values and R-values, but these are steady-state metrics. They don’t account for the rate at which heat enters or exits—a dynamic that becomes critical under real-world conditions like heatwaves, solar spikes, or sudden cold fronts. Thermal diffusivity introduces a time-based layer of control, acting as a “thermal shock absorber” for lightweight or solar-exposed structures.

What is Thermal Diffusivity?

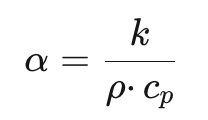

Thermal diffusivity (α) measures how quickly heat moves through a material. It’s calculated as:

Where:

- k = thermal conductivity

- ρ = density

- cₚ = specific heat capacity

A low diffusivity value means heat penetrates slowly — which reduces internal heat spikes, stabilises comfort, and protects against peak thermal loads. This makes diffusivity especially important for lightweight walls, metal structures, and retrofits.

Our coating technology and science works on blocking as much heat as possible through Thermal Diffusivity then what’s left can be considered as conductivity. Thermal diffusivity measures how quickly heat moves through a material in response to temperature changes. It’s the rate at which a material conducts heat relative to how much heat it can store, combining three key properties: thermal conductivity, density, and specific heat capacity. A low thermal diffusivity means heat penetrates slowly, making the material ideal for thermal protection in fluctuating or extreme conditions. It’s not just about resisting heat – it’s about delaying it, which is critical for maintaining thermal integrity.

Why U-Values Alone Are Not Enough

U-values measure total heat transfer, but they assume steady-state conditions. Real buildings experience dynamic spikes: morning sun, winter cooling, heatwaves and night-time drops.

Thermal diffusivity reveals how fast heat enters or exits.

Integrated Thinking:

U-value handles volume of heat loss/gain.

Diffusivity handles rate of change.

Together, they define how a building actually performs.

Together, U-values and diffusivity offer a complete picture of how a wall or roof actually performs – not just in the lab, but in the real world.

Example: Midday Summer Sun (Heat Ingress)

- Reflective Paint Warehouse:

The surface stays relatively cool, but heat still conducts rapidly through the thin coating into the steel — causing the interior wall and air temperature to rise within 10–15 minutes. - Super Therm® Warehouse:

The coating not only reflects solar energy but delays heat movement through the surface.

Result: Interior wall temp remains stable for hours, and internal air temp is reduced by up to 6°C — verified in the City of Adelaide Cool Roof Trial.

Same U-value. Same colour. Totally different result — because of diffusivity.

Example: Super Therm® and US Air Force Warehouse

One the day prior to a symposium and presentation Super Therm® was applied to the exterior of a typical metal building on the US Air Force base that did not have any traditional insulation or drop ceilings. The days preceding the conference and during the conference had ambient temperatures ranging from 43°C to 45°C.

Prior to the presentation and demonstration all air conditioning was shut off for 3 days in order to accurately determine the effectiveness of the Super Therm® in blocking the heat load onto the metal skin of the building. After 3 days in 43°c to 45°C desert heat with no insulation or air conditioning the interior of the metal building coated with Super Therm® was 29°C of the locked metal building.

Same U-value. Same surface. Totally different result — because of diffusivity.

Inside and Outside: Diffusivity in Action

Externally, a low-diffusivity coating like Super Therm® block and delay incoming solar radiation of UV, visual and infrared.

Internally, low diffusivity slows heat loss, creating thermal lag that enhances comfort during cold nights or in fluctuating climates.

Super Therm® is effective on:

- Metal

- Concrete

- Timber systems

…delivering high thermal performance on both sides of the building envelope.

Real-World Validation: Super Therm® Case Study

Super Therm® has been tested under ASTM E1461 (Laser Flash Method) on a metal plate — the correct substrate for real-world application — and achieved a thermal diffusivity of just 0.256 mm²/s.

For reference:

- Aluminium: ~80–100 mm²/s

- Concrete: ~1 mm²/s

- Fibreglass batts: 0.5–1.5 mm²/s

- Super Therm®: 0.256 mm²/s

Super Therm® has one of the lowest diffusivity rates globally for any insulation coating.

Super Therm® outperforms them all and was tested at 23, 50, 75 and 100°C, while also offering:

- Solar reflectance (ASTM C1549)

- High emissivity (ASTM C1371)

- Proven field performance (Australia, Japan, USA)

Additionally:

- Reflects and blocks 96.1% of total solar load – Emissivity, reflectance and diffusivity

- Blocks 99% of infrared radiation

Unlike competitor coatings tested on plastic, Super Therm® provides real-world, substrate-correct data.

Passivhaus Integration

Thermal diffusivity enhances passive performance by controlling peak load dynamics, even when U-values are marginal. In warm-temperate or hot-humid climates, where Passivhaus is harder to meet using bulk insulation alone, low-diffusivity coatings help deliver performance without architectural compromise. Super Therm® can be used in EnerPHit retrofits, especially on corrugated metal or concrete, where traditional insulation depth isn’t feasible.

Passivhaus relies on:

- Airtightness

- Superinsulation

- Thermal bridge control

- High-performance windows

- MVHR systems

Passivhaus Element Breakdown: Where Diffusivity Helps

| Passivhaus Principle | How Diffusivity Enhances It |

|---|---|

| Airtightness | Slows surface temperature fluctuations that cause convection loops |

| Superinsulation | Adds thermal lag, reducing dynamic heat transfer |

| Thermal Bridge Elimination | Slows heat spikes at junctions and frames |

| High-Performance Glazing | Reduces thermal bridging through aluminium frames and reveals |

| MVHR Integration | Stabilises room temperatures, reducing demand fluctuation |

How diffusivity enhances these:

- Slows and reduces thermal bridging across junctions

- Reduces internal temp swings

- Reduces dramatic humidity swings

- Supports EnerPHit retrofits where wall cavity depth is limited

- Stabilises solar-exposed elements both roof and walls

Passive House Planning Package (PHPP) doesn’t currently model diffusivity – but it should.

NCC and BASIX Alignment\For professionals designing under NCC, BASIX, or Passivhaus frameworks — especially those leading performance-first builds — the details matter. Thermal diffusivity offers an elegant yet overlooked upgrade to dynamic thermal management. Here’s where it fills the gaps and supports advanced project outcomes across architecture, sustainability, and building science.

NCC (National Construction Code):

- Super Therm® enhances NCC compliance by reducing roof and wall heat loads, enabling thinner assemblies to meet performance goals.

- Supports compliance with Section J without bulky insulation

- Contributes to fire safety and energy efficiency objectives

- Thermal diffusivity provides dynamic performance that complements Section J’s goal of reducing HVAC energy loads — especially in lightweight commercial or Class 2–9 buildings.

- Fire-resistant coatings like Super Therm® also contribute to compliance with flame-spread and fire resistance requirements.

BASIX (NSW):

- Especially valuable on metal roofs, in hot or coastal climates

- Enhances thermal comfort performance under NatHERS

- Super Therm® can lower internal summer temperatures, especially on lightweight metal roofs, directly improving the thermal comfort and energy usage metrics in BASIX.

- When combined with solar PV and ventilation strategies, Super Therm® supports high-performance, low-cost BASIX scores without thick wall builds.

Standards Integration:

| Standard | Gap Filled by Diffusivity |

|---|---|

| NCC Section J | Reduces dynamic heat gain; complements R-value assumptions |

| AS/NZS 4859.1 | Provides thermal protection in real conditions beyond steady-state lab tests |

| BASIX Thermal Comfort | Reduces indoor temperature spikes — aligns with comfort score modelling |

| PHPP (Passivhaus) | Complements static U-value assumptions with real-world transient heat control |

| EnerPHit (Retrofit) | Enables envelope upgrades without thickness or cavity compromise |

| NCC Climate Adaptation Policies | Supports envelope resilience to heatwaves and temperature extremes |

Example: Cold Winter Night (Heat Loss)

- Reflective Paint Warehouse:

Internal warmth is quickly lost as the surface responds rapidly to outside cold — leading to heat dumping and thermal discomfort. - Super Therm® Warehouse:

The low diffusivity coating slows internal heat loss, keeping inside surfaces warmer longer and reducing demand on heating systems.

Same U-value. Same surface. Totally different result — because of diffusivity.

Expert-Level Considerations

Permeability & Moisture

- Prevents trapped moisture behind substrates

- Super Therm® is water-resistant but breathable, helping prevent trapped moisture while shielding against rain and condensation.

- Water-resistant but breathable – Perm Rating (ASTM D1653-13): 250 microns/0.25mm = 8 perms

- Vapour permeability WVT (Water Vapour Transmission) ratings) (ASTM E96) ensures internal wall drying — essential for timber frames, modular systems, or retrofits in humid climates

- Critical for maintaining structural durability and indoor air quality.

Condensation & Thermal Lag

- While thermal lag reduces daytime heat gain, it must be paired with correct dew point design.

- In winter, delayed surface warming can increase condensation risk if inner surfaces stay cool.

- Best results occur when used in ventilated cavities or confirmed via WUFI modelling — especially in climates like Melbourne, Hobart, or Alpine Victoria.

Mould Resistance

- Low-diffusivity materials stabilise interior surface temperatures and reduce cold bridging, preventing condensation that leads to mould.

- Super Therm® is non-organic and does not support fungal growth (ASTM D3273).

- Ideal for Passive-certified social housing, aged care, and education projects requiring robust IAQ strategies.

Acoustic Performance

- Reduces sound transmission by up to 50-68% – ASTM E90

- Useful in lightweight façades, metal buildings, or near high-noise areas like airports, highways, or urban infill sites.

Fire Compliance

- AS 1530.3 – non-combustible

- ASTM E84 – no flame spread/smoke

- Low VOCs – safe for BAL zones and Class 2–3 buildings (our VOC component gives the coating 20+ years durability to exposed environments)

Suits use in:

- BAL-rated zones

- Multi-storey façades

- Class 2 and 3 buildings, especially in post-Grenfell regulatory environments.

Embodied Carbon

- Ultra-thin system = low material volume and transport energy

- Long recoat cycle = less maintenance, reducing operational and embodied carbon over decades

- Supports performance credits under Green Star, NABERS, and Climate Active frameworks — aligning with Net Zero pathways

- Energy Star, Cradle-to-Cradle, ISO and ABS rated

Substrate Compatibility

- Adheres to metal, concrete, fibre cement and primed timber

- Used at eaves, junctions, parapets, and membrane transitions

Impact on U-Values and Dynamic Heat Load

U-values quantify how much heat transfers through a material, but not how fast it happens. A wall can meet a U-value target yet still allow rapid internal heat spikes if its materials have high diffusivity. By reducing the rate of heat transfer:

- Low-α materials like Super Therm® create more stable internal temperatures

- Reduce HVAC peaks

- Deliver better real-world performance, even when U-values are matched

Why Diffusivity is Ignored

- It doesn’t fit the code-based models (NCC, PHPP, ISO)

- It requires ASTM E1461 (Laser Flash Method) — few products are tested

- It exposes flaws in conventional insulation and reflectance logic

- Marketing prefers to sell R-values and SRI — easy, familiar, low friction

Diffusivity is ignored because it’s disruptive — not because it’s unimportant.

What the Industry is Missing

Without thermal diffusivity:

- Projects misjudge thermal stability

- Lightweight buildings underperform during heatwaves

- SRI-based coatings mislead or ignore internal temps

- Professionals miss a simple solution to peak load risk

Diffusivity is the truth behind thermal behaviour.

R-values tell you how much heat flows. Diffusivity tells you how fast.

Addressing Common Myths

Myth: “If the U-value is low, I’m covered.”

Truth: U-value doesn’t account for thermal response speed.

Myth: “Diffusivity isn’t in the code, so it doesn’t matter.”

Truth: Codes are lagging. Diffusivity reflects real performance under dynamic heat loads.

Myth: “All white coatings perform the same.”

Truth: High reflectance doesn’t mean low heat penetration. Diffusivity determines whether that heat spike reaches inside.

Myth: “PHPP doesn’t model diffusivity.”

Truth: PHPP is a steady-state tool. Diffusivity addresses what it misses — heat velocity and spike absorption.

Myth: “It’s not on the datasheet, so it’s not important.”

Truth: Most coatings don’t test for it. Super Therm® does — independently and under ASTM E1461.

The Future of Passive Design

In a volatile, warming climate:

- The rate of heat transfer matters just as much as resistance

- Comfort, performance, and resilience all depend on dynamic control

- Super Therm® provides that — today

If you’re building to perform — not just comply — thermal diffusivity is your edge. It doesn’t replace what you know. It completes it.

It’s not an alternative to insulation.

It’s the next layer of performance.

And the smartest buildings in the world will use it.

R-values tell you how much heat flows. Airtightness seals it in. But only diffusivity tells you how fast heat moves.

In a warming climate, where buildings face rapid thermal shifts and extreme solar exposure, thermal diffusivity gives you the time delay needed to maintain comfort, reduce mechanical loads, and preserve envelope performance.

Super Therm® leads this evolution with:

- Independent ASTM-tested diffusivity

- Solar reflectance and IR blocking

- Global performance data

Thermal diffusivity is the rate limiter. It buys you time.

In both summer and winter, a low-α material like Super Therm® helps your building resist not just the amount of heat, but the speed it moves.

Super Therm® doesn’t just meet the demands of today…it’s designed for the climate challenges of tomorrow.