Super Therm® sound reduction by 50-68%

For improved sound and acoustics, Super Therm® has a micron sized (not nano) ceramic compound that is so light weight and light in density that it cannot absorb heat and won’t vibrate when sound waves hits it either.

A wall not coated with Super Therm® has density and will vibrate when the sound waves hits it because it allows “sound continuation” due to the substance of the wall board which has density that vibrates.

A wall coated with Super Therm® contains a micron sized ceramic compound which “physically” doesn’t have the density to vibrate and therefore there is a reduction in sound vibration continuation. This is how Super Therm® reduces sound and improves acoustics.

Super Therm® was used in the Mitcham Cinema, South Australia on the walls internally which successful reduced sound transfer between the cinema rooms and also improved fire protection internally.

Super Therm® sounds reduction by 68%

Source: Eagle Coatings

August 25, 2000

Industrial Coatings Alliance Group Inc.

3900 Andrews Crossing

Rosewell, Georgia 30075

Attn. Mr. Dave Phillips

Re: Ultra Sound Testing Super Therm® Coated Trailers

Dear Dave

This letter is to inform you of our Ultra Sound test results. Stoughton Trailers Inc. is the only North American Trailer Manufacturer to utilize state of the art Ultra Sound techniques to provide leak free products to the Van Trailer and inter-modal Container market.

Our verification tests conducted on a Van Trailer with an aluminum roof coated with Super Therm shows that the unit prior to the first application of the Super Therm coating had an average decibel reading of 38. After the first application of Super Therm, the average decibel reading was 25 and after the second and final application of Super Therm, the average reading dropped to 12 decibels.

If you may need any further information, please contact me at 608-973-2605.

Sincerely,

William C. Torda

Manager Total Quality Management

Super Therm Acoustic & Sound Barrier

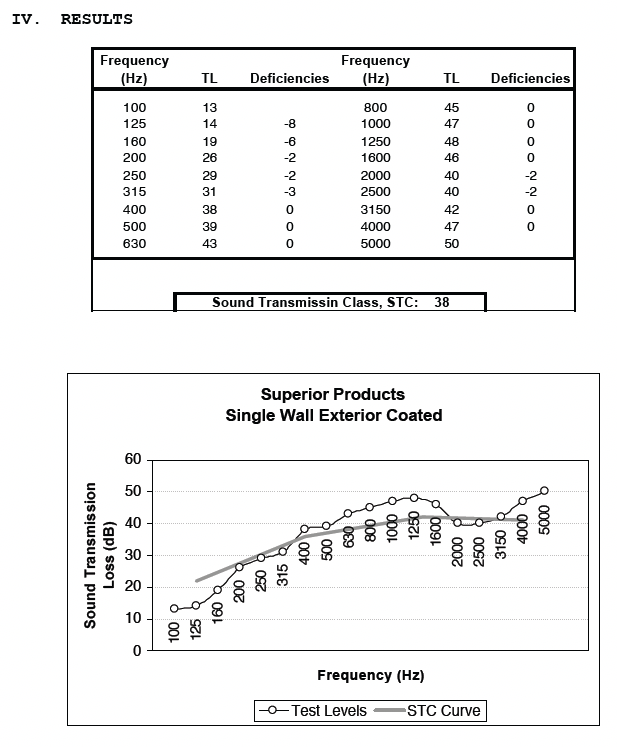

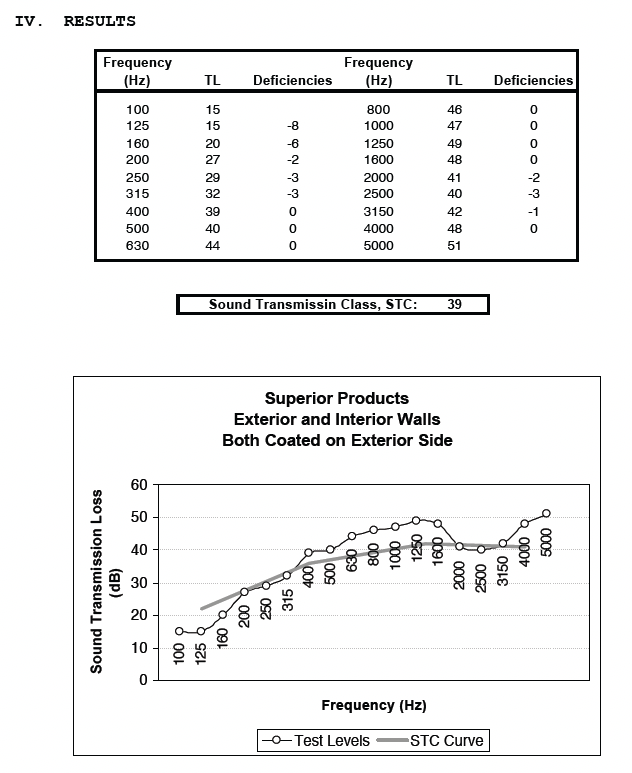

Super Therm 100Hz – 5000Hz frequency testing ASTM E90 and ASTM E413

ASTM E90 and ASTM E413 are essentially the same testing exemplified in IIC (Impact Insulation Class) Coefficient, which is related to the continuation of vibration waves of a specific type of sound, (impact conductance). Measurements are based upon preventing these vibrations or sound continuations.

The test to determine IIC is similar to the STC test. A tapping machine is machine is placed on the floor in the source room (must be second floor or above). The Acoustic Consultant will measure how loud the tapping machine is within the room using an SPL meter. Then, they’ll measure how loud the tapping machine is in the receive room (must be in the room directly below the machine) (source).

Super Therm® is a water-borne, ceramic-filled coating that has four ceramics chosen for insulation and sound reduction. Super Therm® blocks heat and sound by “Stopping The Vibration Continuance”!

A project, known to us as “721 Congress”, involves the use of ICF forms in the construction of a multi-story condominium project. We were informed by LiteForm International that the existing materials will offer an IIC factor of 47. Sound attenuation engineering is an accumulative process, therefore, Super Therm® offers a sound attenuation of 39 at 250 microns dry film thickness, would be accumulative to the existing 47 sound attenuation rating for a cumulative approximate total of IIC-88 on the IIC scale. In addition, we sometimes recommend using HSC or HPC products be applied to ICF polystyrene material prior to the Super Therm®.

- Sound Reduction: STC (Sound Transmission Coefficient) – Rated 38-39 as per ASTM E 90. In the frequency range of 100Hz up to 5000Hz, we hit the 48-51 (which is what the interest level is for talking and normal activity.)

- Stoughton Trailer Ultra Sound testing shows a 68% Reduction

- Sound testing performed by Hot-Cold Air and Fire Control by Pat Saulson, PhD

- Sound reduced an average of 50.2% by using Super Therm® on the interior walls of a house

testing ASTM E90 and ASTM E413 – pdf

testing ASTM E90 and ASTM E413 – pdf

This system offers the consumer the following additional characteristics automatically:

- FM Approval (for insurance reduction)

- “0” Flame Spread

- High resistance to heat transfer

- Mould and Mildew resistance

- UL approval over foam

- Super Therm® is non-toxic and there is no off-gassing during a fire (tested by NASA research labs)

We believe this system to be extremely effective for the purpose of blocking sound as determined and meeting all specifications desired.

About the Acoustic Testing

Due to the heat blocking properties of Super Therm® we considered it also show acoustical insulation properties. In the first preliminary series of tests, a bedroom wall was painted with two coats of Super Therm®. Sound level comparisons from an outside air-conditioning unit were made between adjacent untreated bathroom wall and a Super Therm® painted bedroom wall. Sound meters were placed on the inside of each wall approximately four feet apart, separated by an interior wall. Both meters were located approximately six feet from the outside air-conditioning unit.

In the first series of tests, run for five days, monitors were programmed for five hour periods from 1 am to 6 am, a time when the internal noise level was assumed to be the lowest. The noises coming through the outside walls of the house were assumed to be predominantly from the air-conditioning unit cycling on and off and any ambient nocturnal sounds. A second test series was preformed in which the monitors were programmed for 24 hour periods, for four consecutive days when the house was empty.

The wall was painted on May 20th and sound reports were tracked beginning on May 28th, seven days after application (since Super Therm® requires a seven-day cure time). The sound meters used were designed for comparative purposes, using microphone impulses set on an arbitrary linear scale beginning at zero. Average sound levels for each day for the treated and untreated walls are contrasted in Table 1: Comparison of acoustical insulation ability between a Super Therm® treated wall and an untreated wall.

Table 1: Comparison of acountical insulation ability between a Super Therm treated wall and untreated wall

| Day | Time Period | Super Therm (value range) | Wall Mean | Untreated (value range) | Wall Mean | % Variance |

|---|---|---|---|---|---|---|

| 28/5 | 5 hours | (19-20) | 19.3 | (23-25) | 23.9 | 24% |

| 31/5 | 5 hours | (16-18) | 16.9 | (21-22) | 21.2 | 25% |

| 1/6 | 5 hours | (13-16) | 15.0 | (19-25) | 20.8 | 39% |

| 2/6 | 5 hours | (10-17) | 13.4 | (19-21) | 19.7 | 47% |

| 3/6 | 5 hours | (9-13) | 10.1 | (19-20) | 19.2 | 90% |

| 10/6 | 24 hours | (10-24) | 11.5 | (16-17) | 16.3 | 42% |

| 11/6 | 24 hours | (9-10) | 10.2 | (16) | 16.0 | 57% |

| 12/6 | 24 hours | (9-11) | 10.0 | (15-17) | 16.0 | 60% |

| 13/6 | 24 hours | (9-10) | 9.4 | (15-16) | 15.8 | 68% |

Results indicate that Super Therm® has acountical insulation ability. Percent variances of effectiveness between test periods may be the result of noise generated within the house. Since Super Therm® is reflective by design, any noise occurring in the bedroom would be reflected within the room and transmitted to the microphone. This would result in a few excessively high readings in the 5 or 24-hour periods (most notably, the reading of 17 on 2/6, 13 on 13/6, and 24 on 10/6). High outliers were not noted for the untreated bathroom wall, all means fell close to the value ranges.

Since Super Therm® reflects sound, a better application for acoustical insulation would be to apply the ceramic to the exterior wall of the house so sound generated outside would be reflected away from the house, never penetrating the interior wall.

Its performance is consistent in dealing with how heat and sound waves travel and is not affected by age, moisture, or surface dirt. The four light-weight ceramic compounds contained in Super Therm® are designed to form a crystalline structure. This crystalline structure has very little density and is reflective in nature, so it is resistant to absorb sound or heat.

Quite simply, Super Therm® dampens sound waves before they are allowed to travel to the more dense material coated. If sound waves cannot cause the substrate to vibrate, the sound cannot continue. Super Therm® dampens sound waves. It blocks sound by interrupting the vibration continuance. The essence is to stop sound waves from loading into a substrate which cause vibration. By virtue of the lack of density, Super Therm® will stop up to 68% of sound transmission.

Super Therm® v Fibreglass Insulation Batts for Acoustics

One coat (250 microns dry) on the surface performed similar to 3.5″ of fibreglass that would be placed into a wall cavity. Super Therm recorded STC of 51 at 5,000 Hz which gives Super Therm the ultimate advantage over all other materials trying to offer sound or offer heat blockage when Super Therm does both at the same time and outperforms these standard sound or heat conduction blocks with combined benefits.

Super Therm® v Fibreglass comparison

Here’s a comparison of Super Therm Insulation Coating and Fibreglass Insulation based on their Sound Transmission Class (STC), including actual numbers and pros and cons (ChatGPT generated):

| Feature | Super Therm Insulation Coating | Fibreglass Insulation |

|---|---|---|

| STC Rating (Sound Transmission Class) | Approx. 38-39 (depends on thickness and application) Tests show 51 STC at 5,000 Hz. | Typically 49-53 (varies by thickness and density). |

| Sound Insulation Mechanism | Reflects, blocks and distributes sound waves, nullifying their vibration through the substrate. | Absorbs sound waves due to its fibrous structure, providing improved sound insulation. |

| Effectiveness in Soundproofing | Provides significant sound reduction ASTM E90 and ASTM E413 tested; Ceramics offer multiple properties and benefits. | Reducing airborne sound transmission; commonly used in walls and ceilings for sound reduction. |

| Thickness Required | Minimal thickness (0.25 mm) with excellent STC effects – 250 microns dry. | Requires significant thickness 3.5 inches (8.9cm) or more to achieve higher STC ratings. |

| Weight | Lightweight, does not add significant mass for soundproofing. | Heavier due to thicker installation, adds mass which assists in sound reduction. |

| Installation Process | Easy application, but additional soundproofing materials may be needed for high STC. Quick. | May require professional installation, especially in complex structures. Slow. |

| Durability | Highly durable, design for exterior use of 20+ years. Durable and passive also with thermal benefits. | Long-lasting but deteriorates over time from humidity, dust, compression, sagging, age. Reduced benefits and landfill. |

| Cost | Super Therm has excellent acoustic properties, thermal, fire protection and long lasting around $25m2. | Dramatic price difference. R3.1 ACT Bradford SoundScreen Acoustic Insulation Batts $34.76m2. |

| Best Use Cases | Ideal for all environments with thermal insulation there are side benefits of sound, fire and durability for inside and outside. | Best for spaces requiring significant soundproofing, such as studios or shared walls. |

Summary of STC Performance:

- Super Therm®: Offers an STC rating in the range of 38-39, which provides good sound reduction but is not primarily designed for this purpose. It’s a lightweight coating (300 grams per m2 dry) and easy to apply, making it suitable for environments where acoustic insulation benefits are additional to the thermal insulation.

- Fibreglass Insulation: Typically achieves similar to higher STC ratings of 49-53, making it more effective for soundproofing in serious audio environments. The fibrous nature of fibreglass insulation allows it to absorb and dampen sound more effectively, especially when used in walls, ceilings, and floors.

Pros and Cons:

Super Therm Insulation Coating:

- Pros:

- Lightweight, minimal thickness

- More affordable

- Provides good sound reduction

- Excellent thermal insulation

- Additional fire and mould protection

- Flexible for indoor and outdoor use

- Easy to apply, waterbased and safe

- Cons:

- Lower STC rating compared to fibreglass

- Not specifically designed for soundproofing.

Fibreglass Insulation:

- Pros:

- Higher STC rating (better soundproofing)

- Effective in reducing airborne noise

- Versatile in different building applications.

- Cons:

- Requires more thickness and weight

- More expensive per m2

- Can be difficult to install

- Slower installation and more expensive

- Lower thermal performance compared to Super Therm

- No fire or mould protection.

This comparison gives a clear indication that the two acoustic solutions presented here are fundamentally different on every comparison. However an ultra thin 0.25mm coating of Super Therm v 8.9cm fibreglass to have different STC ratings of 38-39 (up to 51 v 49-53, this is very impressive by Super Therm for its thickness, versatility and durability in more moderate acoustic environments.

One coat (250 microns dry) on the surface performed similar to 3.5″ of fibreglass that would be placed into a wall cavity. Super Therm recorded STC of 51 at 5,000 Hz which gives Super Therm the ultimate advantage over all other materials trying to offer sound or offer heat blockage when Super Therm does both at the same time and outperforms these standard sound or heat conduction blocks with combined benefits.

40% Sound Reduction in Geelong, Victoria

A client had extensive insulation and sound proofing on their home situated on a main road in Geelong, Victoria. Super Therm® was applied to the exterior of the historic weatherboard home at the front and 2 sides. The main issue for the client was they couldn’t afford to pull the walls apart internally to add additional insulation and Super Therm‘s sound reduction and acoustic properties fit the bill.

The client has now received additional fire proof protection but also thermal and moisture protection. Super Therm® did reduce the sound from an average of 42-62 decibels in Sound Transmission Coefficient to now an average of 30-34 decibels. Taking an average of 50 decibels to 32 decibels is a 40% reduction in sound transmission through to the home’s interior. Photos: Thermal360

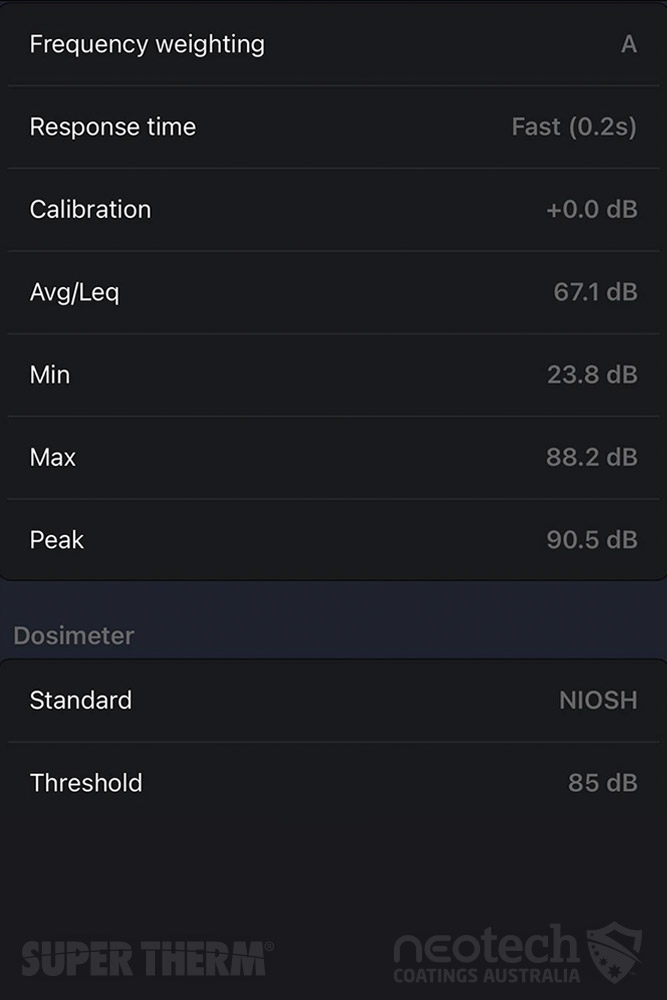

Finally Peace and Quiet for the Parents

A Melbourne home utilised Super Therm® for soundproofing a family home. When you have a family of 4 teenagers, solid timber floor, and they’re all gaming, talking and music, getting sleep is nearly impossible. Prior to applying Super Therm® to the doors and door frames of the home the reading in the master bedroom was 78db and the music was at 90db in the boys room.

Gradually after the applications the room decibel readings went from 43db down to 33db and finally averaging to 33db – 270% reduction. The applicator and the parents couldn’t hear the music in the teenager’s room when in the Master bedroom…Super Therm® more than just heat block but an acoustic barrier.