Super Therm® & White Solar Reflective Paints

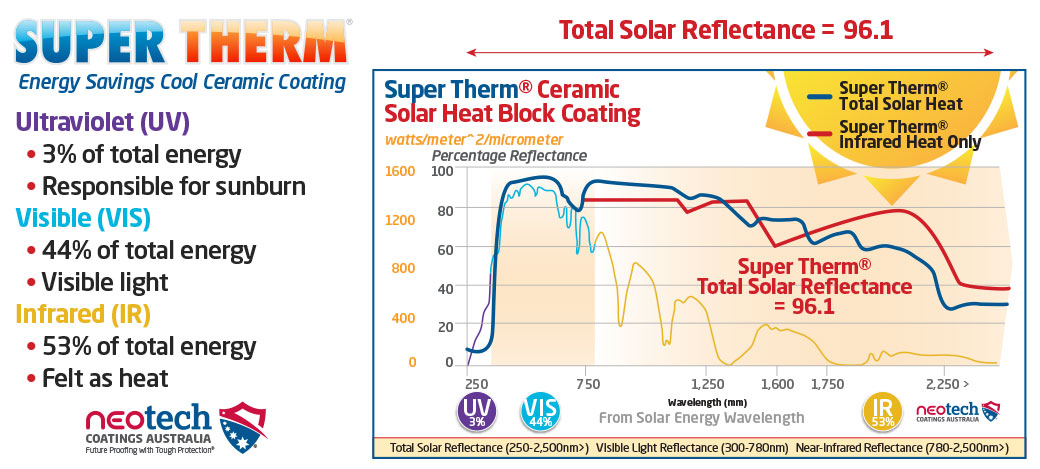

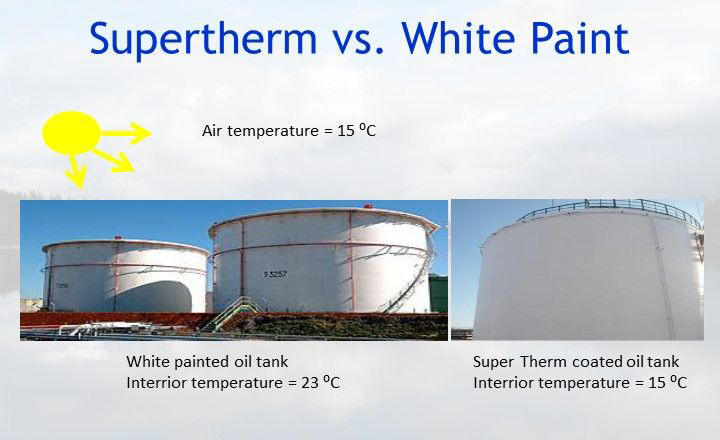

White paint only reflects two elements of heat (UV and Visual Light) and does not reflect infra red heat – 53% of total heat energy…Super Therm® does!

How Does Solar Heat Really Work?

Different Heat Reduction Coating Compounds Compared

Heat as presented is more than solar reflectivity and emissivity; it is also about the heat load. This is the missing part of the formula for true heat management. Find out more >

- White paint only reflects while it is clean, new, white and shiny.

- During summer in the middle of the day with the sun shining brightly, a white car roof will be too hot to touch because of emissivity. Therefore, it is absorbing (not reflecting) heat, and the absorbed heat will transfer to the interior of the car…the same is with any roof or other surface.

- The same roof painted with Super Therm® will be cool to the touch and no hotter than the ambient air temperature as it reflects 96.1% of heat and does not load heat.

- When the exterior of a building is coated with Super Therm®, the result is similar to permanently placing the building or vehicle under a dense shade tree – the heat on the building or vehicle is substantially reduced. Reflective coatings cannot achieve this!

Explanation of emissivity and heat load

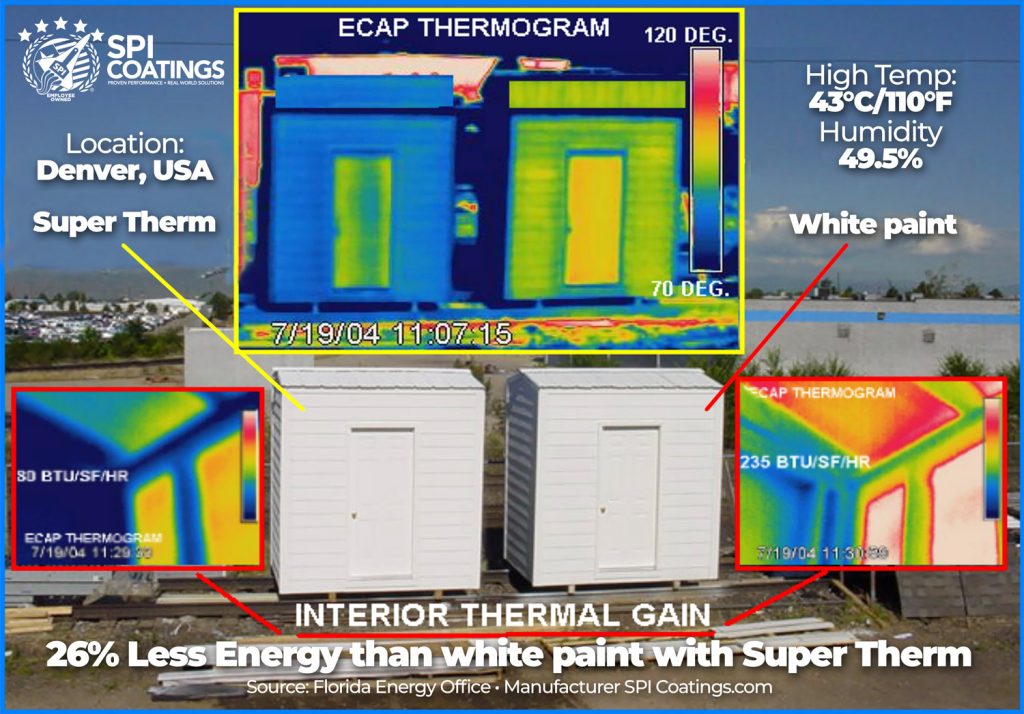

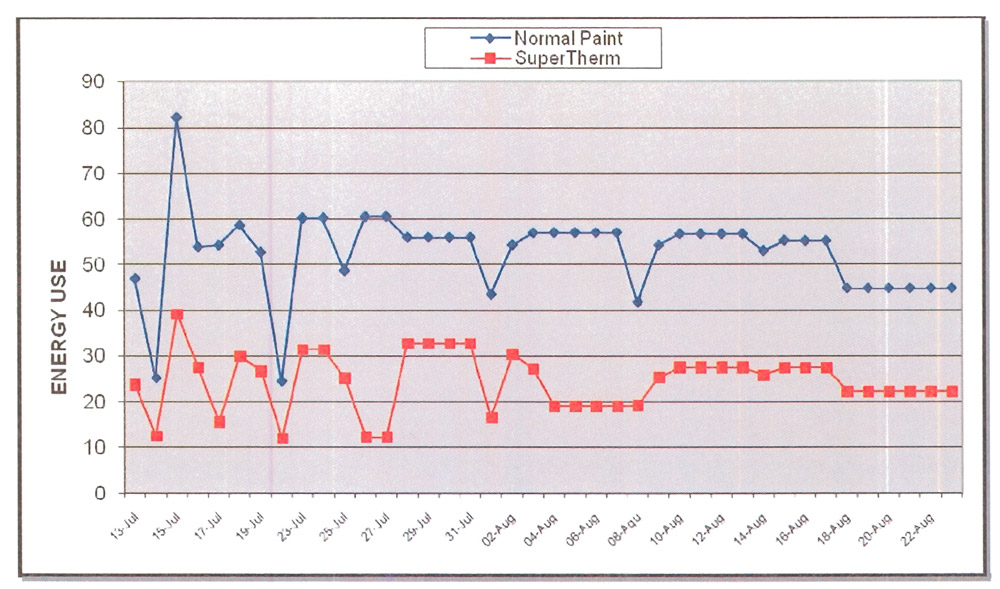

Super Therm® v White Paint – Denver

26-30% Energy reduction

- A 26 to 30% overall increase in energy efficiency

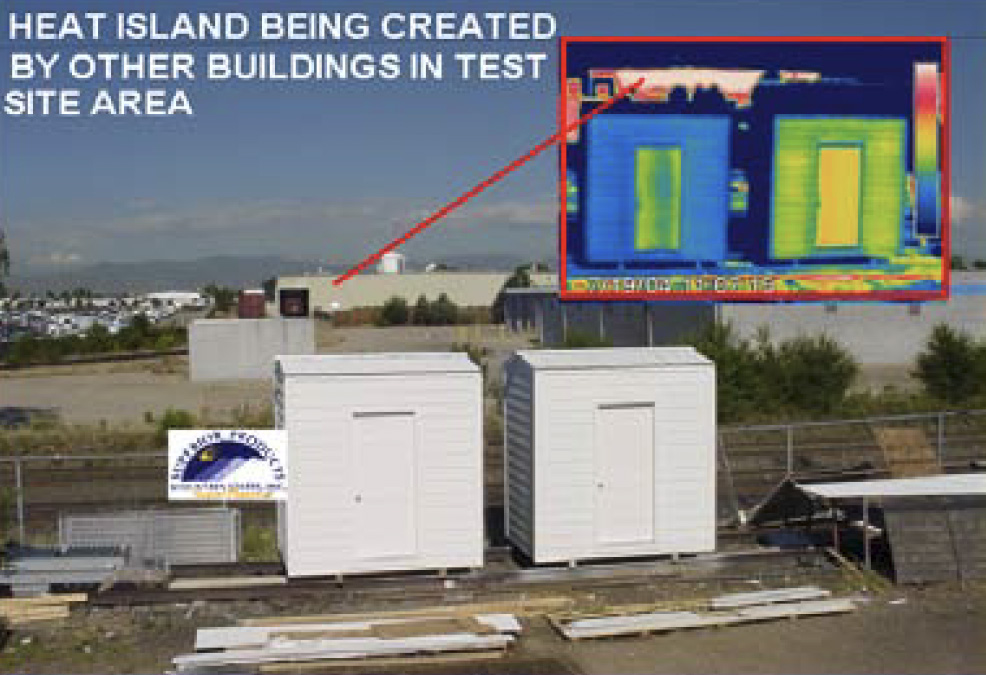

- Reduced Heat Island Effects taking place in most urban areas

On July 19th & 20th, 2004 in accordance with the State of Florida Energy Office / Energy Conservation Assistance Programs Designation: ECAP-CUL-1-03 Method for Comparing Utility Loads in Standard Constructed Buildings in Denver, Colorado.

The objective of this analysis is to determine the impact of the “As Built Conditions and As Installed Components / Equipment” on the utility loads in occupied residential, commercial and government buildings. The focus of this procedure is to provide a comparison to known standards for all parties interested in using alternative energy devices to displaced conventional utility loads. This report reflects the performance characteristics of Super Therm®, as applied to the test facilities external surfaces, as a possible passive Energy Conservation Measure (ECM) to reduce internal Energy Loads and reduce the Heat Island Effects caused by roofing systems in urban areas.

The location of the test specimens was adequate. Both buildings were of standard construction consisting of wood framing, standard OSB wall and roof sheeting’s with a standard galvanised metal roof covering and James Hardey Board external wall coverings. The calculated R-Value of the uncoated existing materials was found to be approximately an R-2.45. The only difference between the two buildings consisting of approximately 48 square feet of control zone area was the external protective coatings.

One of the buildings was coated with a standard white latex paint while the other buildings roof and all external surfaces, including the front door had been coated with Super Therm®. As noted and some of the test results this report the differences created by Super Therm® concerning load reductions produced by thermal conduction, convection and absorption were significant. Additionally, significant reductions in moisture infiltration were also noted.

Our survey indicated that the test specimen’s building envelope related energy loads were reduced approximately 26 to 30% by the use of this particular Energy Conservation Measure (ECM). This was accomplished with no negative effect on the existing buildings Architectural Aesthetics.

Our Energy Flow analysis using a simulated water flow rate of approximately 6.5 gallons per minute indicated that the standard constructed building would require a minimum of 1,037 BTU’s of heating or cooling energy per square foot to maintain a minimal comfort level.

In retrospect, the building coated with Super Therm® reduced these loads to 766 BTU’s of heating or cooling energy per square foot to maintain the same minimal comfort level. This relates to a 26 to 30% overall increase in energy efficiency depending on the percentage of direct solar gain.

While on that subject, our office feels that particularly when addressing external building thermal loads, your product could significantly reduce the Heat Island Effects taking place in most urban areas. The photo and Thermogram below clearly show the benefits provided by your product in this arena.

This is the second time we have had the pleasure to test your product, it is rare that a single product will show such Repeatable Results in two totally different environments, South Florida and Denver Colorado, a true testimonial to your products ENERGY STAR rating.

Data:

- R-Value of the uncoated existing materials was found to be approximately an R-2.45

- The only difference between the two buildings consisting of approximately 4.4m2 (48f2) of control zone area was the Super Therm® external protective coatings

- Highest ambient temperature 43°C/110°F and Humidity 49.5%

- One of the buildings was coated with a standard white latex paint

- Other buildings roof and all external surfaces, including the front door had been coated with egg shell white Super Therm®

- The differences created by the Super Therm® product concerning load reductions produced by thermal conduction, convection and absorption were significant

- Significant reductions in moisture infiltration

- Standard white constructed building would require a minimum of 1,037 BTU’s

- Super Therm® product reduce these loads to 766 BTU’s of heating or cooling energy per f2

- This relates to a 26 to 30% overall increase in energy efficiency depending on the percentage of direct solar gain.

Japanese Institute of Standards

A test piece was taken from a roof in January 2006 where Super Therm® was applied in 1989, and tested at Building Material Test Center in Japan.

The climate is very severe in this area of Kansas with 38°c (100°F) in the summer, sand storms, very strong sun radiation, and -21°c (-5° F) in the winter with snow and ice. The reflectance of near infrared is 67.1%, but this is because the Super Therm® at that time did not contain the fourth ceramic, which was introduced in the year 2000 and designed to block infra red rays. Therefore, the result with the current Super Therm® is better.

Reflective Paints Exposure Testing in Japan

When high reflective paint is applied, the ageing of performance should be considered. A study by Yasushi Kondo for the Tokyo Metropolitan Government, Japan Testing Center for Construction Materials on 21 heat reflective paints showed even the most reflective paint lost it’s solar reflectance by 44% within 1.5 years. It was noted, however there is no authorised standard for performance of high reflective paints in Japan. A standard or qualification system should be considered in Japan. Reflectivity was reduced for other reflective paints was 58% average. This is an accurate view of most reflective paints in the world market (Kondo, 2006).

Super Therm’s loss of solar reflectance in 3 years tested for the Energy Star Program was only 1%.

RESEARCH

Natural aging of cool walls: Impact on solar reflectance, sensitivity to thermal shocks and building energy needs

Wall finishes with high solar reflectance and thermal emittance, commonly known as cool walls, can reduce the exterior surface temperatures of façades, and consequently the building cooling energy needs and power demand, and lower the sensitivity to degradation.

Aging, though, may affect their performance. To investigate this risk, we exposed for four years in Milan, Italy, two series of façade finish coats, white and beige, facing north and south, in vertical and vertical-sheltered position, and we measured their solar spectral reflectance and thermal emittance before and after aging. The solar reflectance of the white finish coats drops from 0.75 to 0.55 in four years, and from 0.46 to 0.38 for the beige coats, while the thermal emittance is unchanged.

Then, for a typical residential building with white walls, we computed that the cooling energy needs increase with walls aging by 5% and 11%, respectively, with or without exterior wall insulation. The exterior surface temperature is increased even by 6 °C, and the number of sudden surface temperature variations in one hour is boosted. Finally, the moisture content in the external layers is reduced, showing the impact on the heat and mass balance because of the uncertainty in solar absorption due to aging. See the report.

Extensive Testing

No other heat block type material has been field tested as extensively as Super Therm®. It has been rigorously field tested and meets the highest standards. The unique formula is UL, FM, ABS, IMO and Coast Guard approved and a VOC Compliant (just 67 grams/litre) water-based coating. Super Therm® has a Class ‘A’ Fire Rating against flame and smoke. Plus, it is USDA approved for use in and around food preparation areas.

White Phone Containers v Super Therm, Turkey

For transmitting the reception signal for mobile phones in Turkey, an air-conditioned container with electronic equipment is used. The problem is that the containers can overheat with extreme outside temperatures (30°C+) with the result that the equipment will malfunction or even break down.

One of the parameters is that the container had to have a constant inside temperature of 24°C that could often not be reached with the air conditioner that was used.

The problem is that there are significant electricity costs for cooling the container to the right, constant temperature of 23°C. The containers are 2 x 2 x 3 meters, which are 24m2 for the entire container, bottom excluded.

Treat the container with Super Therm® on the outside to reflect the direct sunlight, so that the air-conditioner can reach the inside temperature of 23°C more easily and that eventually energy reduction will occur.

Conclusions: Inside temperature of 23°C was reached. An average energy reduction of over 50% was achieved. See the report >

RESEARCH

Effects of Natural Weathering on the Performance of High Solar Reflective Index Paint Surfaces Exposed in Harsh Climatic Conditions of United Arab Emirates

Solar reflective index (SRI) is one of the important parameters in the analysis of a building’s energetic and thermal performance, especially for “cool” reflective paints or coatings. However, there exists less information on the typical performance of the cool materials exposed for long term in the Middle East and more specifically in the United Arab Emirates (UAE).

In this study, they determined values of reflectance, emittance, solar reflective index (SRI), and colour difference, for three different high SRI white paints exposed naturally on low and high sloped racks for three years. After 3 years, reflectance values of exposed paint panels significantly decreased with an increased colour difference in comparison with original unexposed paint surfaces. Emissivity of the paint changed very little for all of the exposed samples, but SRI, determined from both the reflectance and emittance, was reduced from between 95 and 110 to between 60 and 90 after three years.

This appeared to be related to exposure to high temperatures, UV radiation, and adhesion of airborne contaminants in conjunction with low precipitation. Macroscopically, panels exposed on a low slope were the most discoloured with the greatest presence of dust infusion and reduction in increase in surface temperatures which was demonstrated through thermal imaging. Such natural weathering research study is necessary for the development of standard exposure tests and determination of various control elements to increase the durability of cool materials in hot and arid climatic conditions of UAE. Read the report.

Cool Roofs and Solar Reflective Paints

Dr John Pockett from the Barbara Hardy Institute from the University of South Australia gave a presentation. Here’s some excerpts from his research and findings:

- Exposed metals (Zincalume & galvanised) are poor at giving off heat (low Emissivity) so they become hotter than most other materials having the same TSR. This is between 12 and 20 degrees Celsius hotter than materials having the same TSR. As Zincalume ages, the TSR decreases but there is an increase in emissivity due to the oxide layer on the surface so the excess temperature over normal materials becomes less.

- The TSR is the reflectance of a surface weighted for the relative intensities in incoming sunlight. You can’t achieve good TSRs if you have a low reflectance in the visible (dark colour) no matter how good your IR reflectance is. The critical part of the spectrum is the region between 700 and 1100 nm where intensity is relatively high. If you can efficiently reflect IR in that range there is less absorbance causing the surface to heat up. With appropriate scatterers by whatever means there can be a substantial lowering of absorbance and surface temperature. The eye’s sensitivity in the 600 – 700 nm region is already falling off so it is possible to cheat a little with the visible colour match and already be boosting reflectance slightly lower than the nominal 700 nm cutoff.

- The benefits of heat reflective paint in lowering surface temperature are relatively small for the cooler light coloured paints. The larger benefits for darker colours just mean they go from being abysmal to just being very bad in surface temperature. The main benefits of the heat reflective paints is that they are usually formulated so that the surface is harder and/or slipperier. Different manufacturers will differ markedly in their ability to formulate their heat reflective paints to shed dirt, moulds etc.

Additional studies into the degradation of solar reflectance

There have been multiple studies and real-world observations showing that the reflectance of white paint decreases over time due to weathering, dirt accumulation, biological growth (such as algae or mould), and material degradation. Here are some key sources and findings:

U.S. Department of Energy & Lawrence Berkeley National Laboratory (LBNL) Studies

- Studies from LBNL’s Heat Island Group have examined how white roofs and high-albedo coatings degrade over time. They found that:

- White coatings can lose 20-50% of their initial reflectance within the first few years due to dirt accumulation and surface degradation.

- Cleaning can restore some of the reflectance, but not always to the original level.

California Energy Commission & Cool Roof Rating Council (CRRC)

- CRRC’s long-term monitoring of cool roofs found that:

- Solar Reflectance of white roofs declines significantly over 3-5 years due to soot, organic debris, and microbial growth.

- Factory-applied white coatings tend to last longer than field-applied paints, but all see degradation over time.

Florida Solar Energy Center (FSEC)

- The FSEC tested white and reflective coatings in Florida’s humid and sunny climate, noting that:

- Humidity accelerates reflectance loss as algae and mould thrive on surfaces, even if the coating is designed to resist bio-growth.

- UV exposure causes chemical degradation of some coatings, reducing their initial reflectivity.

Super Therm® compared with Thermoshield ALL4RVS blog

A blog ALL4RVS posted a comparison article of Thermoshield vs Super Therm®. Makes for interesting reading if you’re in the market to block the solar heat on your RV, Caravan or bus.

The Verdict

Based on these analyses, we can see that primarily their performances in heat reduction are neck in neck. But if we look at their other properties and benefits, I can say that Super Therm® is better in the account of the following:

- Less volume of coating required and less weight added on the RV

- Ability to reduce noise too

- Extensive case studies and strong partnerships with reliable organisations

- Well-trusted not only in its origin country but also to other countries worldwide – one of which is Australia of course

Comparison of Super Therm® to other reflecting coatings on the market

When tested for Energy Star Program

In the government testing procedures on the products by Insulating Coatings Corporation, Temp-Coat Brand Products, LLC, and SPM Thermoshield, Inc. dba Roof Guardian when tested for Energy Star Program, the testing was performed to demonstrate the reflectivity of a new roof and of a three-year old roof to determine the reduction in reflectivity/performance and loss of insulation effectiveness.

See the original report of the Energy Star Program at www.energystar.gov.

This comparison testing shows very clearly that Super Therm® is the best coating on the market to maintain its insulation ability over the years. The other coatings must be reapplied to maintain any insulation ability. Super Therm® does not have to reapplied.

Full report pdf

| Product | New Roof Reflectivity | 3 Year Old Roof | Percentage Reduction in Reflectivity |

| Aztec 900 | 86% | 77% | 10.5% |

| Warranty of 10 years would mean that at the end of 10 years the reflectivity would be reduced by a minimum of 30% | |||

| Temp Coat | 87.7% | 61% | 30% |

| Warranty of 10 years would mean that at the end of 10 years the reflectivity would be reduced by a minimum of 90% | |||

| Thermo-Shield | 84% | 63% | 25% |

| Warranty of 10 years would mean that at the end of 10 years the reflectivity would be reduced by a minimum of 75% | |||

| Super Therm® | 80% | 79% | 1% |

| Warranty of 10 years would mean that at the end of 10 years the reflectivity would be reduced by less than 0.04% | |||

Competitors using Super Therm images

They say imitation is the sincerest form of flattery so we were surprised when a Super Therm® competitor decided to use our images in their cool roof presentation!

In a presentation to the Alternative Technology Association, Melbourne Branch on Cool Roof Coatings, Perry Eckert from Nutech Paint Pty Ltd utilised two Super Therm® projects promoting Cool Roofs. An image on page 19 is of a Super Therm project from Chile and on page 70 a project from Nissan, Japan that’s been mislabelled ‘Very large factory roofs in California US’. See our Nissan project here.

Clearly Super Therm‘s been around since 1989 and its nice our competitors wish to promote our successful projects…perhaps they should credit the images to Superior Products International II, Inc. and Super Therm®. Goes to show even our competitors love Super Therm® they’re happy to show off in the presentations. https://renew.org.au/wp-content/uploads/2018/12/cool-roofs.pdf

International Papers

- On the ageing of cool roofs: Measure of the optical degradation, chemical and biological analysis and assessment of the energy impact

- Experimental characterization of reflective coating material for cool roofs in hot, humid and dusty climate

- Thermal Performance of Thermal Paint and Surface Coatings in Buildings in Heating Dominated Climates – The evidence from the results and models, as well as scanning electron microscopy, do not support the claims that the additive powder particles are effectively nano-porous, evacuated, or that the coatings have low emissivity surfaces. Competitors make claims of additives that add not thermal property benefits unlike Super Therm.