Heat Blocking, Reflectivity, Emissivity and Emittance…the Facts!

With the popularity growing for cool roofs and the phrase SRI (Solar Reflectance Index) there’s become a need to find the latest buzz words for depicting radiational heat absorption, reflection and heat blocking mechanisms. Emissivity is the most important of these buzz words that can be seen as easily misunderstood by anyone trying to put a spin on what it is. Let’s break it all down.

A US Energy Authority (that tested Super Therm three times showing 20-50% energy reduction) defines the Solar Reflectance Index (SRI.) as ‘…a measure of the roof’s ability to reject solar heat, as shown by a small temperature rise. It is defined so that a standard black (reflectance 0.05, emittance 0.90) is 0 and a standard white (reflectance 0.80, emittance 0.90) is 100. For example, the standard black has a temperature rise of 90 deg. F (50 deg. C) in full sun, and the standard white has a temperature rise of 14.6 deg. F (8.1 deg. C). Once the maximum temperature rise of a given material has been computed, the SRI can be computed by interpolating between the values for white and black.’ (source).

The point of a phrase or buzz word seems to show a mechanism of explaining how reflectivity but mainly the ability of a coating surface can repel heat off its surface back to the atmosphere thus reducing the amount of heat available to “emit” through the surface film to the cool side. Emissivity is assumed as the best and easiest word to utilise this heat repelling phenomenon. There is a direct relationship between emissivity and emittance.

SRI Calculation Forumla (Excel)

If a heat reflective paint “loads heat” internally, then the emissivity number has no real to a very low importance.

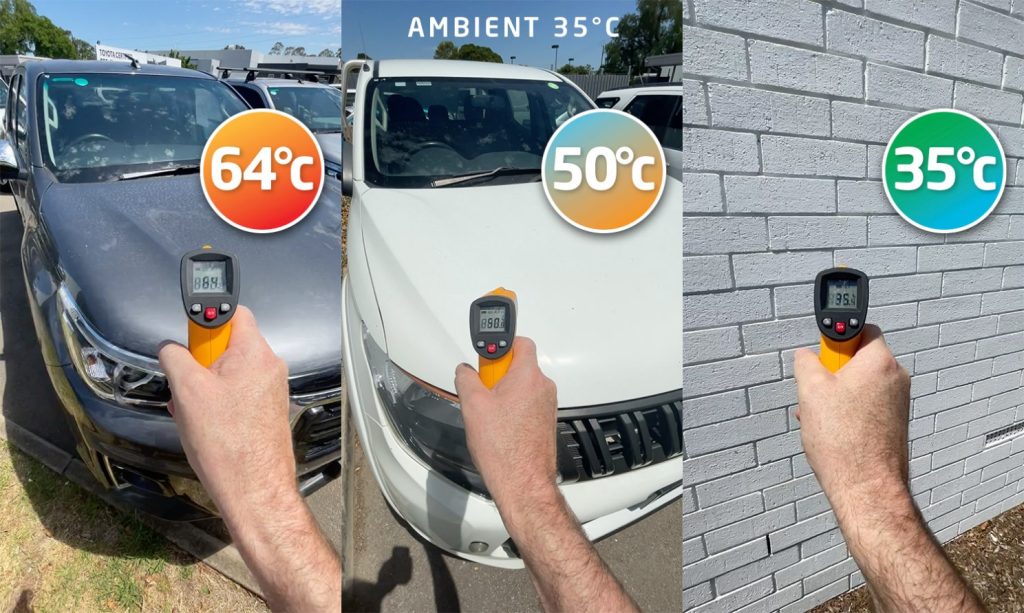

Since white paint is recorded by test equipment that by design only catches light bouncing off a surface and it registers 70% reflectivity, does this mean that all white surfaces block 70% of the “radiation heat” sunlight from loading onto a surface which it covers? Absolutely not! You have a white car bonnet.

Example: On a 35°C day, the surface of the shiny white bonnet can average 50°C with darker colours it’s showing a 64°C+ surface temperature. Our shiny white car absorbs the infrared conductive heat through the car’s paint and loads into the metal because of the metal’s density which stores heat. That is solar absorption and heat load.

Reflectivity test equipment cannot pick up “heat” which is the main discussion point. It picks up certain nanowaves of the light spectrum with “shiny” or gloss getting a lot of air play – which has nothing to do with heat. So, given the above, reflectivity does not show how heat is managed, only light reflected.

Reflectivity does not show how heat is managed, only light reflected

Emissivity is given a lot of air play too with the latest and greatest attempt to discuss and explain heat management. As we read research reports which seem mostly a regurgitation of what has been written before, this becomes the latest spin, however we find big issues in these reports. Remember that emissivity was originally and still is defined as – based on a black box, absorbs 100% of the heat and then equalises this heat absorption with the surrounding atmosphere by giving off 100% of this absorbed heat back to the atmosphere through emissivity. This is the scientific background to get the 1.0 as the basis that all emissivity is measured against.

Emissivity is based on a black box which absorbs 100% of the heat and re-emits it back out

Now, you have scientific testing machines to try and find the emissivity of how good the surface of a coating or film can throw off heat from its surface. They arrive at 0.85 up to 0.95. Everyone thinks this is fantastic because the surface can throw off excessive heat at such a high rate and therefore be an excellent repeller of heat off the surface. Not really.

As an example: emissivity of 0.91 (surface heat thrown off to the atmosphere) resulting in an emittance of 0.09 or heat not blocked that is able to transfer to the cool side. In some of the latest research studies published in November, 2021, this relates to a high R-value in their effort to show the comparison of initial heat blocking (insulation coatings) directly to heat absorption and slow transfer materials like fibre.

Lets’ go back to the very beginning of how you measure emissivity. A black box absorbs 100% of the heat and equalises itself by emitting this 100% absorbed heat to the atmosphere. 100% absorbed and 100% emitted off. All emissivity is based on this black box or blackbody effect. Except in how the emissivity is being related in these new studies, the amount of heat absorption factor is being completely ignored. Everyone is forgetting that heat absorption is not part of this equalisation reaction that started the concept of emissivity.

The amount of heat absorption factor is being completely ignored with SRI by researchers and industry

In our studies with NASA Space Agency from 1989 to 1995 when ceramic compounds were taken individually or one-by-one to test the “dry” compound as to how well it can reflect heat, while maintaining its’ level of emissivity to throw off this surface heat to the atmosphere, was the key to long term performance. Then the same compounds were incorporated into a paint formula making it wet and mixed with the usual paint ingredients, question was how well does it continue, if at all, to reflect and have good emissivity.

It was effected and was amazing how much change or percentage drop the reflectivity and emissivity had if made into a paint formula. This is where we see the “general statements” about ceramic compounds being able to reflect heat and have good emissivity all at the same time based on totally untested assumptions. We tested thousands of compounds, over many years and none of this one-on-one testing of each compound is published anywhere, the individual performance characteristics of each compound are not published. Therefore, none of this research is known by the engineering community. Our experience is that if no testing is published, then none of the research is valid and cannot be supported by chemistry or engineering because they cannot validate the results.

The six years spent with NASA is documented, but not a single firm wanted to spend the time and money on testing one compound at a time to find the ones that would work. Like Graham Bell, from over 7,000 compounds tested we had thousands of failures before finding the success. No firm will pay someone to do this which makes this type research unique and very solid. Testing compounds one-by-one to prove or disprove the performance value is the only way to know for sure.

Missing: How much heat did the paint or compound actually absorb during the exposure to the sun radiation?

The important point that has been excluded from all the papers written is: How much heat did the paint or compound actually absorb during the exposure to the sun radiation? If it had an emissivity of 0.90, did this mean the compound or reflective paint “absorb” 0.90 heat only to equalize itself back to the atmosphere? Like the black box. Before anyone claims they can separate emissivity percentage or number of a surface, they must know how much heat was absorbed by that same surface.

The perfect combination

In J.E.’s research since 1989 of ceramic compounds of every type it was discovered to resist heat load, you must find the ceramic compound that resists heat absorption due to it’s low density and because the compounds’ physical make up of crystalline structure also allows for a high rate of emissivity. Super Therm® contains the perfect ceramic compound combination that do not absorb heat inside the coating, yet the coating still has a high emissivity of throwing heat off the surface. This make the balance of Super Therm’s formula unique to the market in that it cannot absorb heat and yet has a high emissivity. The heat absorption is being totally disregarded by all others.

This combination of characteristics you “must” have for a true insulation paint to perform over 30 years, becoming dirty, weathered but only dropping a few degrees of performance over all this time and weathering.

You must have this combination of qualities to allow the coating to consistently repel the “loading” of heat, while at the same time throwing off the surface heat to the atmosphere at a high rate. In other words, this combination separates itself from the black box concept. It did not absorb heat equal to its tested emissivity.

This is the performance concept characteristics completely missed by researchers and others.

This is why Super Therm® has performed for since 1989. The combination of low heat absorption while maintaining a high emissivity is why the customer gets their ROI so effectively. Other heat reflective paints do not have the studied ceramic compounds resisting ever loading heat and maintaining their high emissivity. If a heat reflective paint “loads heat” internally, then the emissivity number has no real to a very low importance.