What is SRI or Solar Reflectance Index?

SRI stands for Solar Reflective Index. It’s not an absolute measurement of heat transfer but a relative measurement of reflectivity and thermal emittance but does it really cover the full issue related to the ‘best’ heat index? Before we go further it’s our opinion that SRI as a standard is more an average than being efficient or effective. Let’s discuss why.

Read our post on Linked In: Is SRI really an Effective Cool Roof Standard?

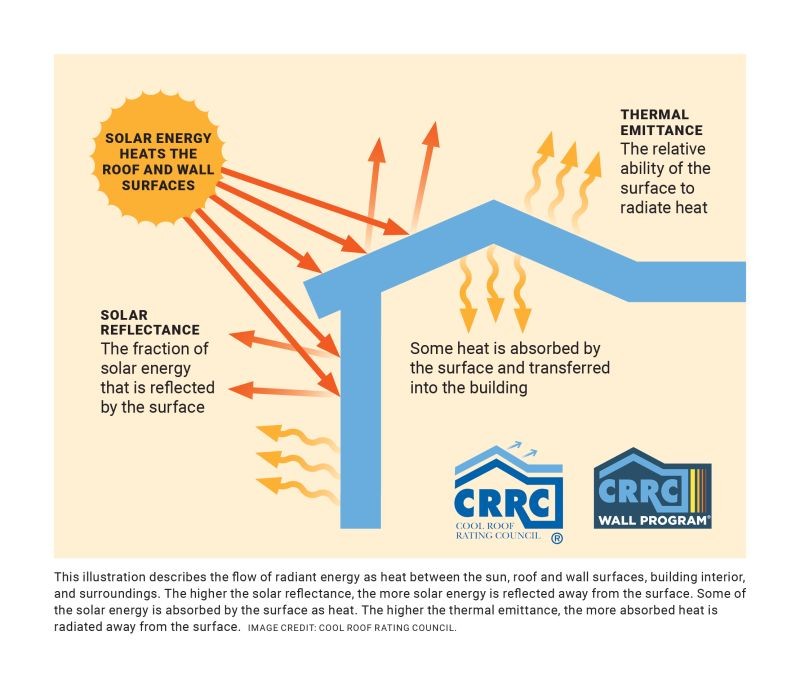

Solar Reflectance

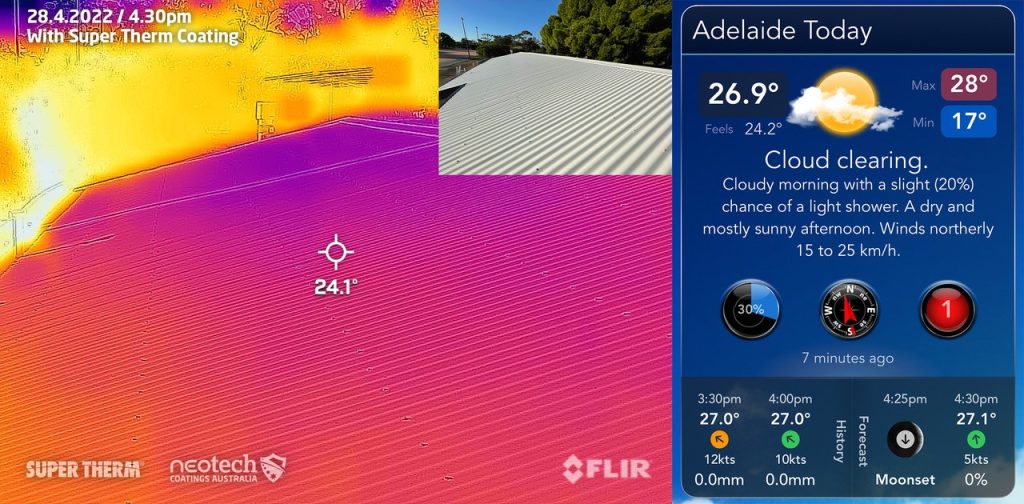

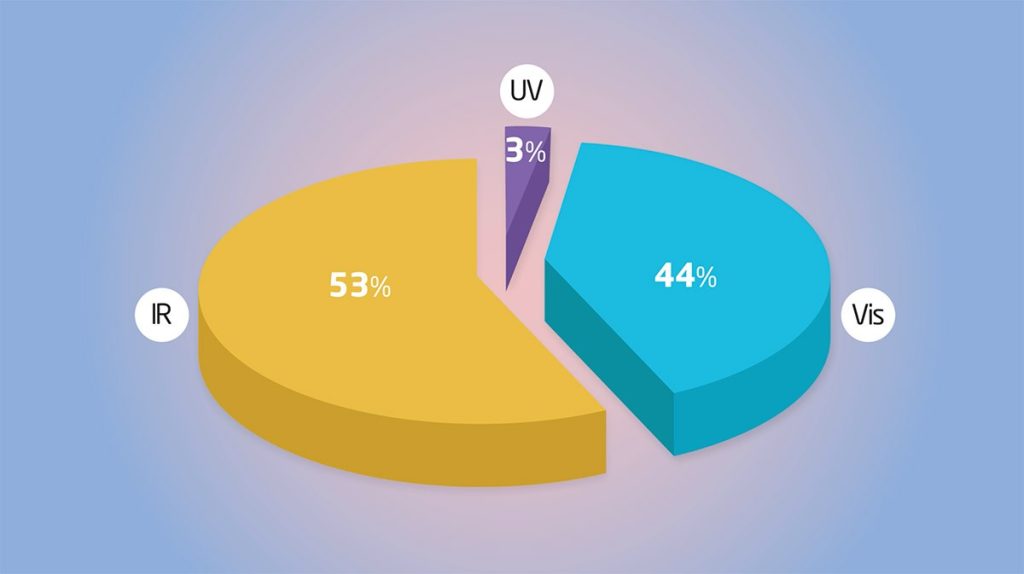

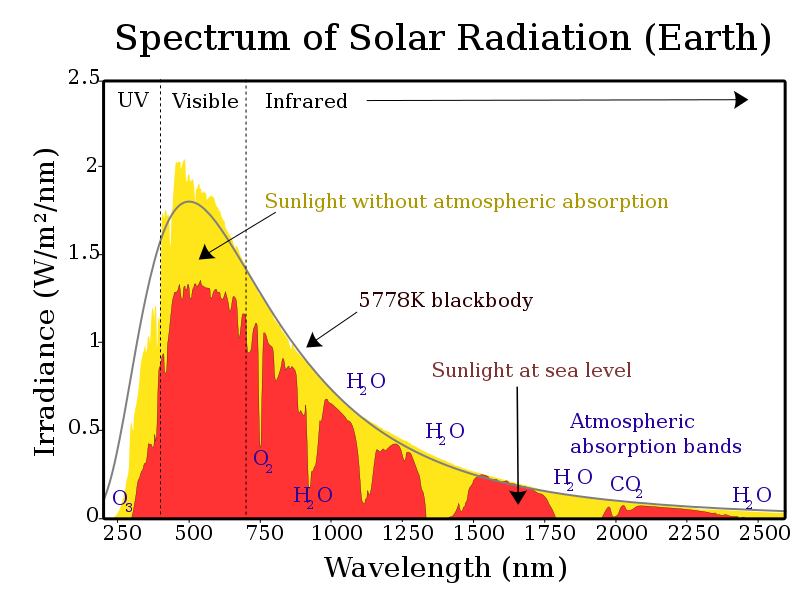

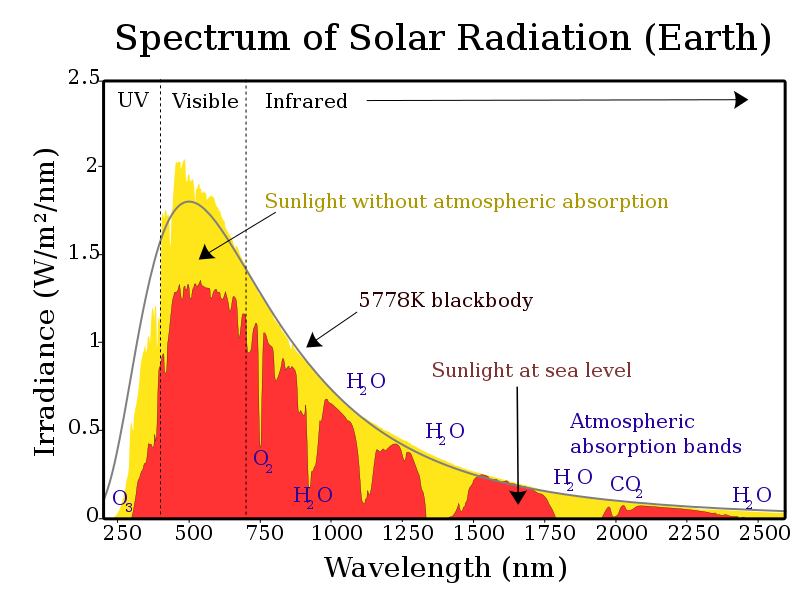

The first part of SRI is made up from Solar Reflectance or reflectivity. Solar reflectance (sometimes called albedo – Latin: albedo, meaning “whiteness”) is about light and not the total sum of solar heat blocking. As CRRC states above “the fraction of solar energy that is reflected by the surface”. White paint has around 80% reflectivity, which means it reflects 80% of visual light (less if dirty) which is 44% of the total solar heat. Meaning standard shiny white paint reflects approximately 35% (80% of 44) of the total solar heat (if 80% reflective – worse if dirty). Infrared heat makes up 53% of the solar heat and UV only 3%. Even claims by scientists that the “whitest” of shiny white paints can reflect 98% (43% of the total heat) of sunlight (Sparkes, 2021) yet they don’t mention what sunlight or solar heat is made of. They mean visual light heat, not infrared. Solar thermal heat comprises of:

- Infrared – 53%

- Visual – 44%

- UV – 3%

The total nanowaves of sunlight are infrared, visual and UV and they all carry heat. Infrared carries the most and this is converted as watts of energy that enters the building or any surface as conductive energy.

For SRI’s to work the CRRC stated “the fraction of solar energy that is reflected by the surface”, and the UNSW stated “the solar reflectance defines how much the incident solar radiation is absorbed by the surface”. Therefore shiny white due to it’s solar reflectance should reflect most of the heat…and be better than solar absorption as a measurement of heat, definitely not! Solar reflectance doesn’t affect the total incident solar radiation absorbed by the surface, reflectance doesn’t affect infrared which is absorbed.

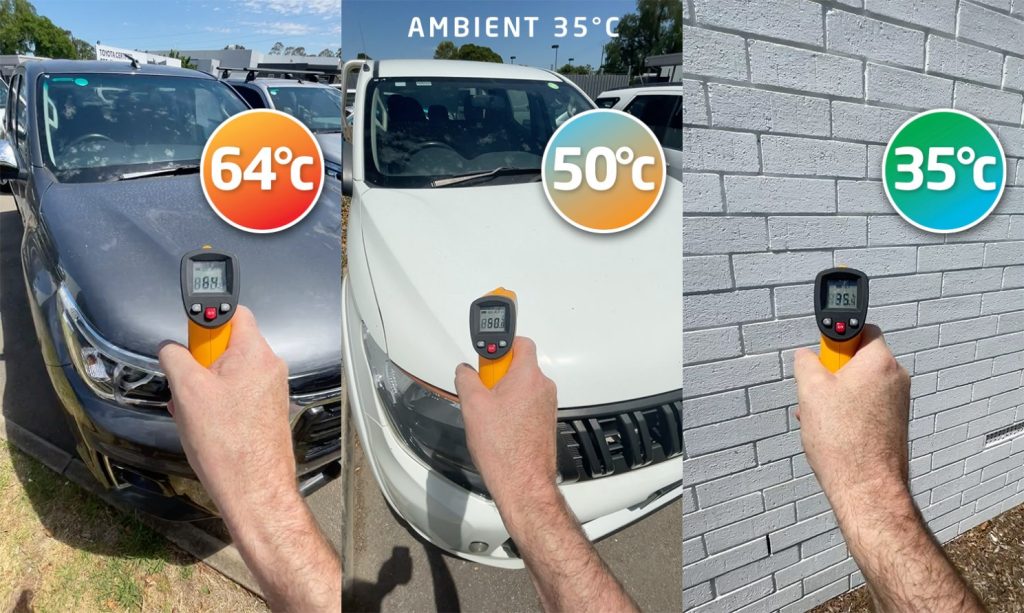

Here’s the catch with shiny white paint. As an example on a 35°C day, the bonnet of a SHINY WHITE car is 50°C (42% hotter than ambient) and the DARK car is 64°C (82% hotter than ambient). If the SHINY WHITE paint blocked 100% of the solar heat absorption, the temperature of the SHINY WHITE car would be near ambient or near 35°C and not 50°C. The shiny white paint doesn’t block infrared heat…just visual heat.

Once the conductive solar heat from infrared passes the white pigments it is loaded into the metal’s substrate. No longer is SRI effective. That’s why when you touch a SHINY WHITE car on a warm day the surface is still very warm to hot and can burn your skin. The misnomer that shiny white paint is a better solar reflector isn’t factual over coatings that also block the infrared heat and reduce heat load transmittance.

Riccardo Paolini – Associate Professor at UNSW

I am the first to say the BCA should include emissivity. Anyhow, the SRI uses solar absorbance (300-2500 nm, thus whole solar spectrum) and thermal emittance (whole thermal IR spectrum), not just colour in the Vis range. What it doesn’t count is the transmission through the envelope, so products that provide some thermal insulation would need to be added the additional thermal resistance in the energy balance calculations. The reason why the SRI is like that is because otherwise one wouldn’t know where to stop counting the layers and some might come with a black (SR 0.05) membrane coupled to a 200 mm insulation claiming it blocks the total solar heat gains.

Also, SRI doesn’t work for walls or green roofs. For some situations (e.g., green roofs) an SRI equivalent might be meaningful. There’s no consensus on the metric though. It’s not perfect and I don’t use the SRI in research papers, but it’s a scale and it goes beyond colour. The most accurate metric preferred by researchers doesn’t always get used in practice, and we cannot expect everybody to run climate modelling to make a project choice. Then, performance solutions give quite some flexibility. I acknowledge there is margin for improvement in the codes there.

Essentially Riccardo’s comments on SRI still don’t address the solar transmission and important of absorbing infrared heat into the building. SRI is not about measuring heat load or transmittance, this is about emissivity or heat being released. This is why SRI isn’t a valuable scale of thermal performance, in the end we need to know how much heat is being absorbed.

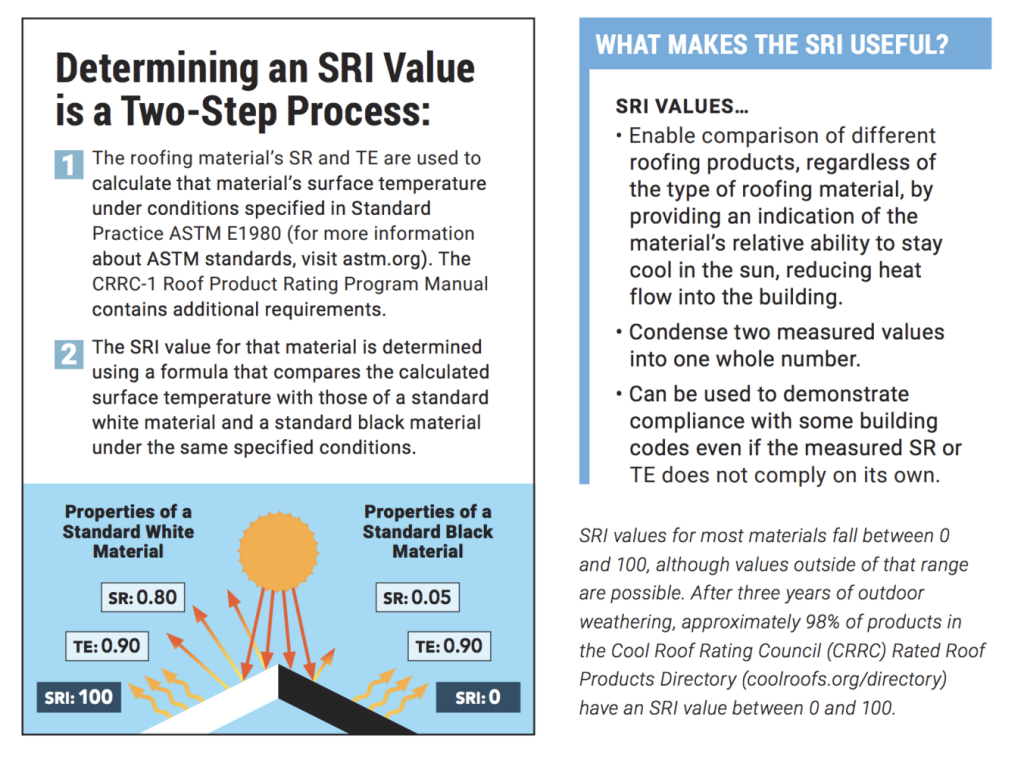

How is SRI determined?

Regulation makers and the construction industry have favoured the use of parameters that allow the forecasting of the interaction between different material properties without the need for complex analyses. Among these, the solar reflectance index (SRI) takes into account solar reflectance and thermal emittance to predict the thermal behaviour of a surface subjected to solar radiation through a physically rigorous mathematical procedure that considers assigned air and sky temperatures, peak solar irradiance, and wind velocity (Muscio, 2018). You can download an Excel document for SRI here.

SRI is based on the hypothesis of an adiabatic irradiated surface and does not consider the insulation or the inertia of the materials below, nonetheless it can again work well as an indicator of the heat transmitted by convection to the external near ground air because the heat flow rate conducted to the ground or through a roof can be lower by one or two orders of magnitude than solar irradiance (Muscio, 2018). In the end it’s all about what’s above the surface and not underneath and there’s assumptions made as both hypothesis and indicators only.

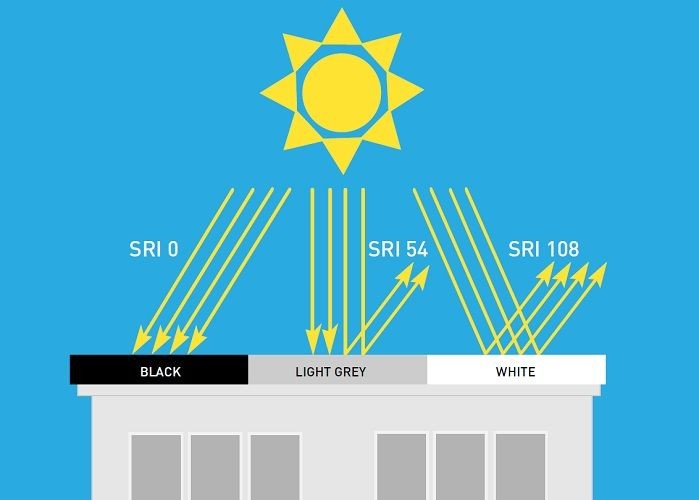

(Image above: Understanding the Solar Reflectance Index from CRRC) ASTM E1980-11(2019) as specified above by the CRRC is based on Standard Practice for Calculating Solar Reflectance Index of Horizontal and Low-Sloped Opaque Surfaces.

1. Scope

1.1 This practice covers the calculation of the Solar Reflectance Index (SRI) of horizontal and low-sloped opaque surfaces at standard conditions. The method is intended to calculate SRI for surfaces with emissivity greater than 0.1.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

Even in the description from the CRRC doesn’t give any thermal value or solar absorption value from the SRI definition. How this standard is adopted with zero actual thermal benefit is peculiar to say the least and the whole world is caught up in it.

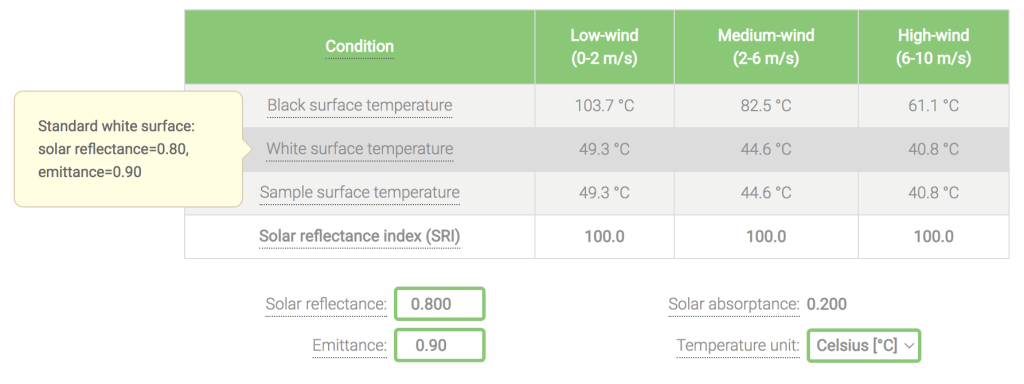

This is perfectly reflected in the OTM Accredited Laboratory (OTM Solutions, 2021) above as recommended for white paint shows their calculation based on solar reflectance of .80 and emittance of .90 has an SRI of 100. Interestingly the surface temperature they calculated is 49.3°C on a low wind day, identical to our white car example but what is the ambient temperature? 35°C or 41% hotter than ambient?

According to Berkeley Labs (Berkeley Labs, n.d.): This index is calculated following ASTM Standard E1980-11 using a roof product’s solar reflectance and thermal emittance values. The SRI calculation can also be used to estimate the surface temperature of the roof product under prescribed conditions. The key here is to create a steady-state surface temperature (Ts)—While you can go to the ASTM Standard for the formula, under point 5. Significance and Use it states:

Solar reflectance and thermal emittance are important factors affecting surface and near-surface ambient air temperature. Surfaces with low solar reflectance, absorb a high fraction of the incoming solar energy. A fraction of this absorbed energy is conducted into ground and buildings, a fraction is convected to air (leading to higher air temperatures), and a fraction is radiated to the sky. For equivalent conditions, the lower the emissivity of a surface the higher its steady-state temperature.

So again the ASTM standard focuses on surface and air temperatures and not heat load. Interesting it discusses low solar reflectance therefore higher temperatures. The method described above gives the SRI of surfaces based on measured solar reflectances and thermal emissivities of the surfaces therefore not the U value or any allowance for infrared heat transmittance into the building. SRI matches the need of a single performance parameter as it allows to easy comparison of the performance of different solar reflective solutions (Muscio, 2018). Yet still no value for the heat absorption into the building!

Reflectivity test equipment cannot pick up “heat” in light which is the main discussion point. It picks up certain nanowaves of the light spectrum with “shiny” or gloss white getting a lot of air play – which has little to do with heat. So, given the above, reflectivity does not show how heat is managed or transferred.

Image: On-site albedo measurement. Thermacs Engineering (Themacs Engineering, n.d.)

Point 1: The solar reflectance portion of SRI doesn’t define how much incident solar radiation is absorbed by the surface. Only what’s reflected by light.

Our SHINY WHITE car above absorbs the infrared conductive heat through the car’s paint and loads into the metal because of the metal’s density which stores heat. That is solar absorption and heat load. This is the same as the metal roof on your building. So in reality, solar reflectivity testing is only about light and some of the nanowaves for visual heat but not the full heat spectrum which means the solar reflectance part of SRI doesn’t measure the heat transfer or absorption into the surface which is critical for heat management and energy assessment.

Dr. John Pocket from the University of South Australia outlines in his paper “Heat Reflecting Paints and a Review of Their Advertising Material” Advertising of heat reflective paints often refers to insulation properties; however, restricting heat flow through paint films is not a significant part of the benefits of heat reflective paints (Pockett, 2010). The predominant factor relating to reducing solar heat load on buildings and pipework is the Total Solar Reflectance of the exterior surface and not thermal conductivity. There is a lack of technical accuracy in much advertising material.

It is recommended that funds be sought to carry out completely independent testing of a range of heat reflective paints on the Australian market under standard testing conditions. This is because of the importance of reducing energy usage, particularly with sharp peaks of electricity usage on hot summer days and the need to know which paints actually work effectively (Pockett, 2010).

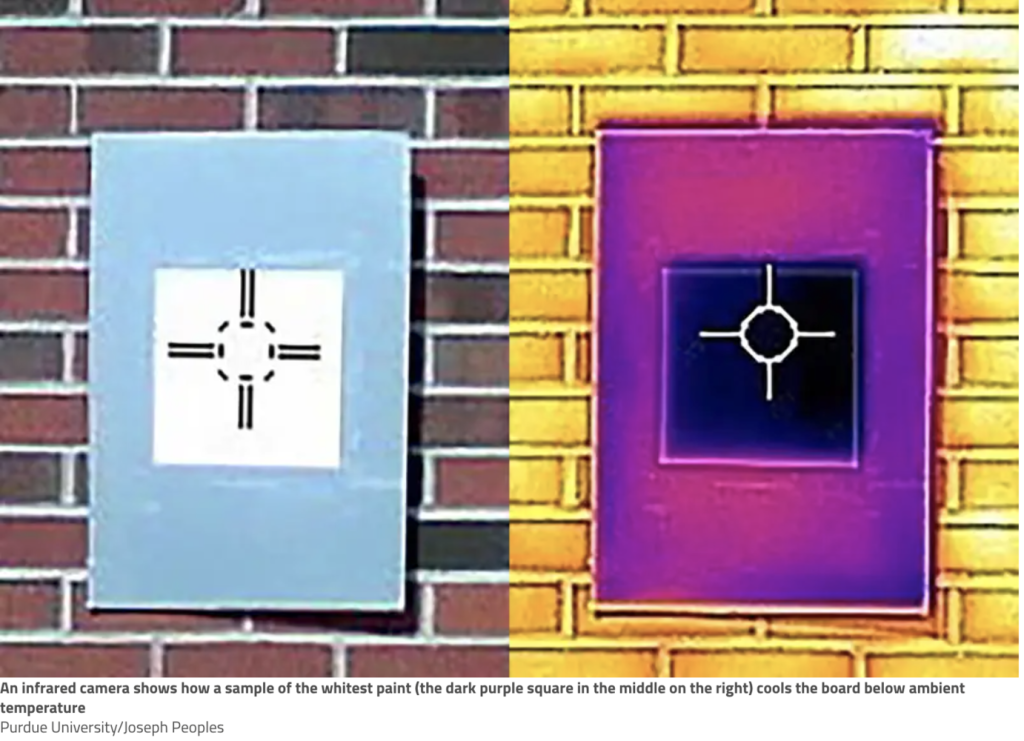

White will cool a portion of the surface it’s on. In the photo above from Purdue University (Sparkes, 2021), the board is cooler but so is the lighter blue because its not absorbing as much heat in relation to the solid heat mass of the dark brown brick wall behind. There’s very little density in the paint sample unlike the bricks. The paint’s main ingredient is Barium Sulfate. A better example is to put the “whitest” paint up against standard white and show the IR camera range of temperatures. Better yet, paint a portion of the wall so it shows the substrate covered with their ‘whitest paint’ in comparison to the wall that has the density…paper doesn’t have density. Ironically according to the IR camera image, the blue board isn’t much warmer than the white paint because of colour and density.

Claims of paint are made regularly based on how ‘white’ and ‘shiny’ it can be with very little actual data disclosed behind the results or reference to infrared heat.

Xiulin Ruan at Purdue University states he is now working on an even more reflective material but says that there may be diminishing returns. “Pushing to 100 per cent is hard. You will get 19 watts per square metre more cooling benefit, so practically it may not be that attractive given the cost,” he says (Sparkes, 2021). It highlights there’s still a high amount of solar energy transfer from infrared portion of the heat and what are the commercial realities or costs of these “whitest” paints or their proven performance and verified field results.

It was noted the heat reflective paint above helps with some heat load but not that much as you must “load” the coating film very heavy with the Barium Sulfate compound to work. If the surface is loaded too much with Barium Sulfate it will not adhere to the surface and crack – like a dried river bed. Barium Sulfate (BaSO4) is a white, heavy insoluble powder that occurs in nature as the mineral barite (NEOtech Coatings, 2022). Again, this relies on being white and no validated data on heat transmittance or heat load.

Point 2: Most of these examples only show white is cooler which we know but doesn’t give any hard evidence or results for net energy gains or savings. This is common in many claims of white paints, coatings and films for cool roofs.

So ultimately solar reflectivity doesn’t measure infrared heat in the heat spectrum and relies on being as shiny, clean and white as possible which means if it’s dirty, tinted or weathered, the efficiency of the paint to keep reflecting solar heat is diminished. Without infrared heat blocking in the formulation, white paints will be 44% hotter than ambient.

Point 3: Solar reflectivity isn’t a measurement to gauge total heat absorption; it’s about light reflection…not heat!

White is only Good while Shiny and Clean

Solar heat is more than solar reflectivity and emissivity; it is also about the heat load. This is the missing part of the formula for true solar heat management. Shiny white paints and coatings rely on selling the idea they need to be shiny to work, this is because they don’t block the infrared heat. SRI with only up to 3 years testing could mislead consumers for value when the shiny white paint starts to perform less.

Even the CRRC state: SRI values for most materials fall between 0 and 100, although values outside of that range are possible. After 3 years of outdoor weathering, approximately 98% of products in the Cool Roof Rating Council (CRRC) Rated Roof Products Directory have an SRI value between 0 and 100. This shows deterioration in 3 years…how about 5, 10 or 20 years? Due to its reflective nature:

White paint only reflects while it is clean, new, white and shiny. Why spend thousands on a paint that doesn’t perform or last?

In fact, some cool roof paints offer a warranty they stipulate that their product must be cleaned regularly between 6 months and 2 years…this is a fundamental issue of using SRI based on solar reflectivity and shiny white which negates the purpose of effective energy efficiency. How many people want to clean their roof every 6 months to keep the warranty. It also means that a fear of many consumers is high visual reflectivity that impacts visual appeal. Coatings don’t need to be shiny and are more effective if the formulation is correct.

Reflective Paints Exposure Testing in Japan

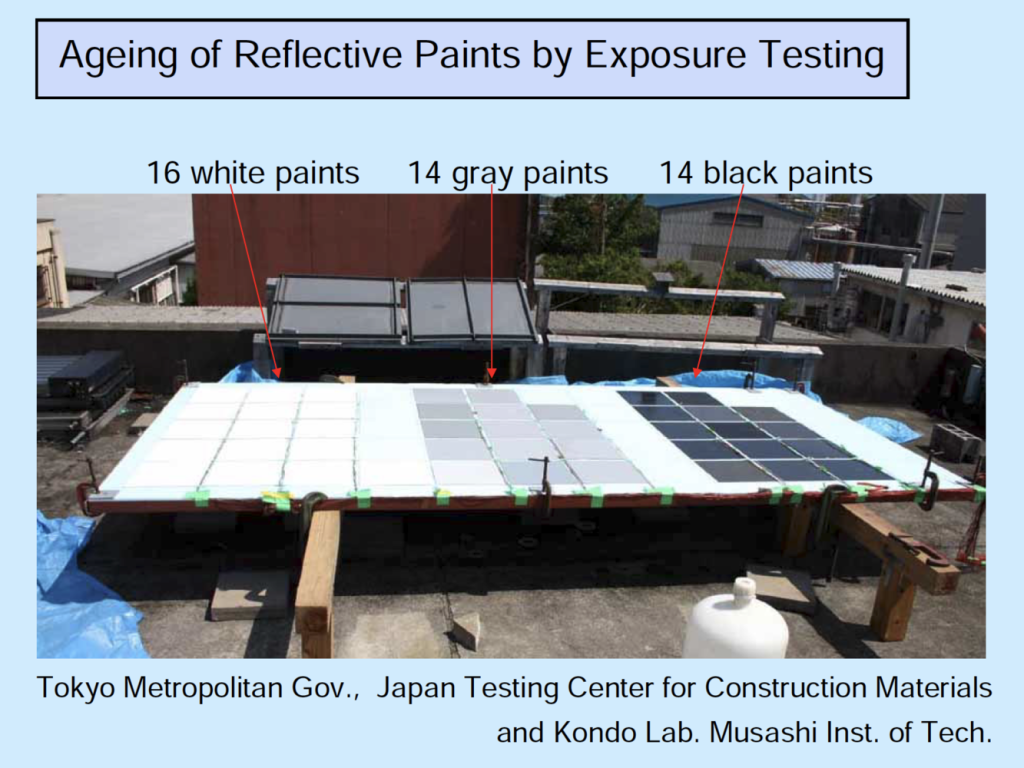

When high reflective paint is applied, the ageing of performance should be considered. A study by Yasushi Kondo for the Tokyo Metropolitan Government, Japan Testing Center for Construction Materials on 21 heat reflective paints showed even the most reflective paint lost its solar reflectance by 44% within 1.5 years. Reflectivity was reduced for other reflective paints was 58% average. This is an accurate view of most reflective paints in the world market (Kondo, 2006).

Image: A study by Yasushi Kondo from Musashi Inst. of Tech. for the Tokyo Metropolitan Government, Japan Testing Center for Construction Materials in 2006 on 21 heat reflective paints showed even the most reflective paint lost it’s solar reflectance by 44% within 1.5 years (Kondo, 2006).

The aged radiative property ratings are recommended to be 3 years by the CRRC USA. This again makes little sense as these coatings are expected to last at least 10 years for their customer’s investment and return. Ratings should be giving testing periods of 3, 5 and 10 years allowing for coatings and paint companies to offer consumers more advantages that have proven longevity. It will show evidence of reliability, reflectivity, thermal transfers and therefore consumer value.

Point 4: Shiny white reflective paints will drop in reflectivity and therefore the long term investment will diminish so correct longevity ratings will help consumers and industry…3 years isn’t long enough as solar panels are expected to have a 10-25 year life.

Thermal Emittance

Okay, what about Thermal Emittance the other part of SRI. Thermal emissivity is the total thermal heat re-emitted from the substrate back to the atmosphere. This solar heat has already been absorbed as infrared heat through the surface, paint or coating like the SHINY WHITE car we’d discussed. Thermal emittance is the relative ability for the roofing material or coating to re-radiate or emit absorbed heat as conductive infrared heat back into the atmosphere; the quicker the heat is released the better. The longer the heat is trapped at the surface of the roof the hotter the roof is both inside and out.

Emissivity is given a lot of air play as well with the latest and greatest attempt to discuss and explain heat management. Many research reports seem to mostly regurgitate what’s been written before, this becomes the latest spin, however there’s big issues in the interpretation of emissivity facts. When applied to roofs and pavements, SRI is a clear indicator of the capability of their surface to return the incident solar radiation to the atmosphere by direct reflection and far infrared radiation (Muscio, 2018). Absorption is a different question.

Remember that emissivity was originally and still is defined as – based on a black box or blackbody, it absorbs 100% of the heat and then equalises this heat absorption with the surrounding atmosphere by giving off 100% of this absorbed heat back to the atmosphere through emittance. This is the scientific measurement to get the 1.0 as the basis that all emissivity is measured against. It still loaded 100% of the heat which transferred to the interior or cooler side. Isn’t it strange that white cool coatings are using black as the basis of emissivity ratings. We’ll explain further.

Emissivity is based on a blackbody which absorbs 100% of the heat and re-emits it back out

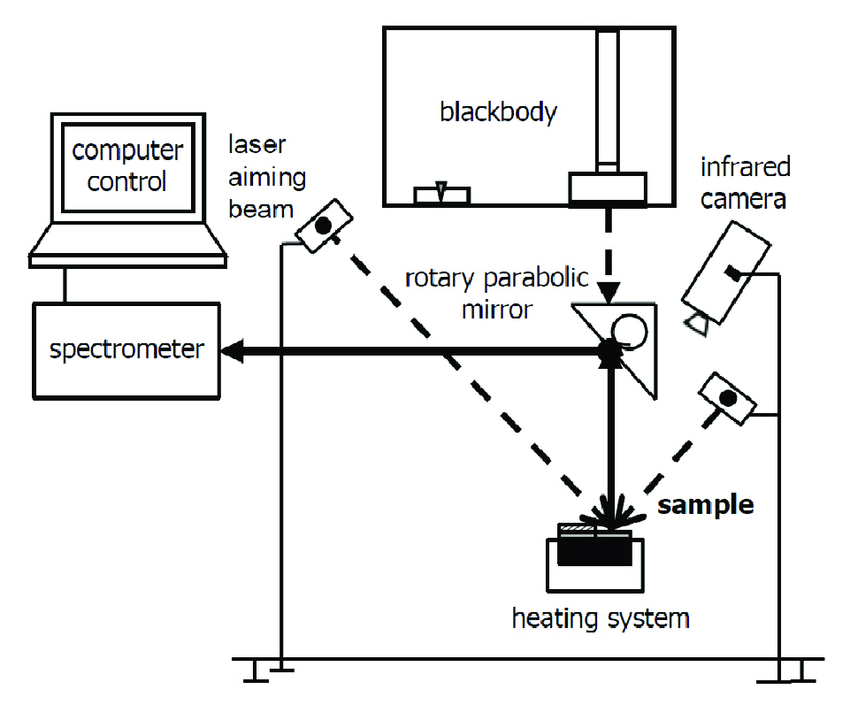

Image: Schematic arrangement of the emissivity measurement method (Mauer, Milan & Kalenda, Petr & Honner, Milan & Vacikova, Petra., 2012).

If an emissivity rating is .91, does it mean that 91% of the heat load is thrown off the surface? Well no. Everyone thinks this is fantastic because the surface can throw off excessive heat at such a high rate and therefore be an excellent repeller of heat off the surface, not really. No matter the emissivity number, the surface loads all the heat it can which is allowed through, then transfers it into the building to equalise.

The benefit of a high emissivity rating is the ability for the heat to be released from the coating or paint quickly to the outside…what about the inside? The concept of an emissivity rating is like having an umbrella made from a flyscreen that allows the rain through while trying to measure how quickly you can dry while still being rained on.

The question is how much heat was actually “loaded” or absorbed by the coating film/substrate “before” the emissivity released heat from the surface?

New galvanised iron as an example is a poor emitter of heat. It has a low rating of .23 because it holds the heat longer on the surface and despite the myth of galvanised iron being a good reflector, new galvanised iron isn’t good for thermal benefits related to cool roofs. Older galvanised iron is better at .88 yet still allows enormous amounts of heat to load. Concrete has a high emissivity level of between 0.85-0.95 (Engineering ToolBox, n.d.).

So the question is how can reflectivity which measures light only and emissivity that measures emittance of heat released give any valued data on the thermal effectiveness of cool roof paints and coatings when heat is transferred into the substrate.

If enough people tell you something is true you start to believe it

Lets’ go back to the very beginning of how you measure emissivity. A black box absorbs 100% of the heat and equalises itself by emitting this 100% absorbed heat to the atmosphere. 100% absorbed and 100% emitted off. All emissivity is based on this black box or blackbody standard. Except how the emissivity value is being related to in these studies and ratings for paints, the amount of heat absorption factor is being completely ignored. Everyone including researchers, engineers, academics and industry are forgetting to mention or even know that heat absorption is part of this equalisation reaction that started the concept of emissivity.

The amount of heat absorption factor is being completely ignored with SRI by researchers, academia, engineers and industry.

Emissivity as the key to repelling heat from loading into a coating film is completely wrong when it could only equalize the amount of heat that is loaded in the first place.

Blocking initial heat load is the key. If the surface emissivity is high meaning the infrared that either did load or tried to load was thrown off, this is good, but the actual heat load that happened before the emissivity reacted is the key. Stopping transmittance is better than reflectance and emittance. In order to do that you need to block the infrared heat at the surface before transfer.

Blocking the actual load of heat into the coating film is the key

Simplistic Advertising of Heat Reflectivity Paints

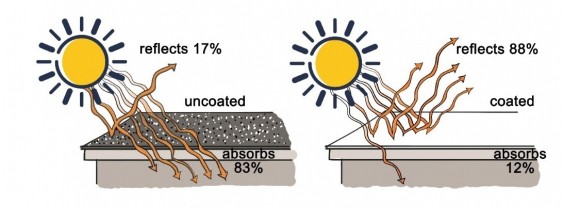

Below are common examples of how graphics regularly show SRI heat reflecting but what does it really say and it doesn’t truly explain how much heat is being transferred through. It’s essentially misrepresenting heat and stating with the arrows that most of the heat is being reflected by the white yet it isn’t like our white car example. Consumers, industry and government are misled by these diagrams because consumers don’t understand how heat works, how substrate densities make a difference, what cool roof products do and the differences between them all.

Image: UNSW – Are cool roofs the future for Australian cities? (Razzhigaeva, 2022) The image above show’s numbers but no verified data or ambient temperature. We’ll use the example of the white car with the ambient of the roof above as 35°C.

88% of 35°C is 39°C. In reality, like the white car bonnet the white roof temperature would be 50°C without the infrared heat blocking compounds. Therefore the white roof above is reflecting 80% (white solar reflectance) of the 43% of visual heat ordinarily.

White is absorbing more heat into the substrate than you’re aware of. All and every claim should be linked to disclaimer with proven results and show testing result details for infrared, UV and visual heat. As advertising standards aren’t regulated these images are very misleading and in fact misrepresent SRI’s true thermal results.

Point 5: Simple diagrams give zero education of true solar heat absorption but ‘infer’ white paint is reflecting more heat than it is.

The reality is while global temperatures climb so will the percentage of heat absorption. Knowing the difference between white paint and a total solar heat block coating will be crucial for effective decision making and results.

If the ambient temperature is 45°C then the white paint will be 63°C which is near 20°C hotter without blocking the infrared.

Image: Simple graphics like above show ‘what‘ SRI is yet don’t give consumers any accurate facts about solar absorption. In fact there’s zero indication there’s any solar absorption which is very misleading (Image: Gudelevičius, 2022).

In November 2016, The Federal Court ordered DuluxGroup (Australia) Pty Ltd (Dulux) to pay penalties totalling $400,000 for making false or misleading representations about the temperature reducing characteristics of two paint products, in proceedings brought by the Australian Competition and Consumer Commission. From June 2009 until September 2012, Dulux promoted its heat-reflective roof paint, InfraCOOL, as a paint that could reduce the interior temperature of the living zones of a house by up to 10 degrees (ACCC, 2016).

This practice continues through the industry in different ways such as misleading inappropriate R values of coatings which you cant achieve, temperature reductions and how long the coating or paint lasts. It’s unregulated wild west country in cool roof products yet there are companies and products with integrity. If you can’t see the data and testing results you should be wary.

The Solar Reflective Index is determined through solar reflectivity and emissivity…it doesn’t add up or connect to the purpose of measured true thermal and energy efficiency and performance in buildings, occupant well being or cost savings. Even statements the building will be ‘4°C cooler’ is based on what modelling, testing and results?

The essence of energy savings long term is a measured way of blocking the heat load and heat transfer.

Understanding Heat Transfer in Heat Load

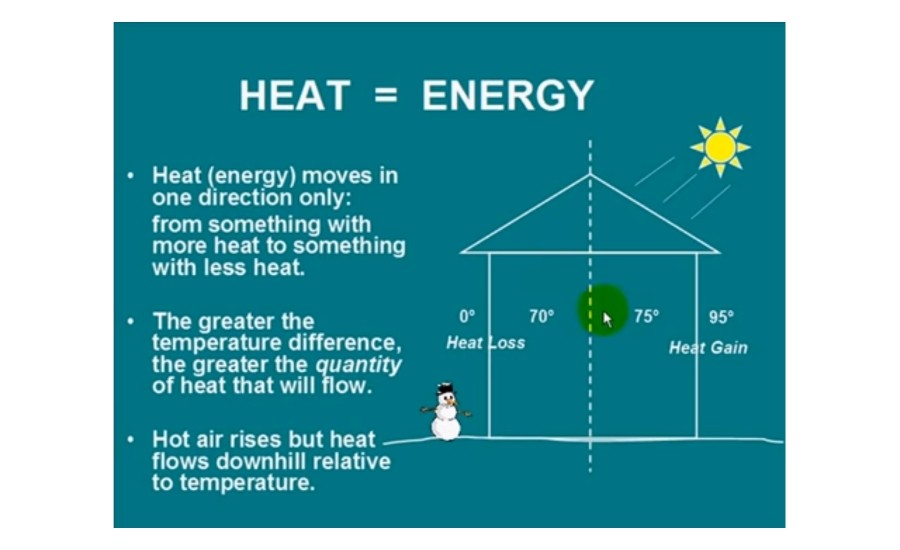

Image: (Meaney, 2020)

How much heat (energy) moves depends on how big the surface is, the density, how well it is insulated, and how hot and cold the two sides are. Of the three types of heat transfer, conduction (others are convection and radiance) is usually the first thing to understand when it comes to heat load. The maths is straightforward (BYJUS, 2020) and the concept is simple. If a barrier (like a roof) separates something hot from something cold (like a cool house on a hot day), the heat will move from hot to cold. While traditional insulation resists the heat flow, eventually that insulation hits a level of heat flux (full heat load), that is the heat has transferred through to the cool side. This works in reverse in winter.

Heat flux describes the rate of heat energy that passes through a surface. Depending on its exact definition, its unit can be expressed as either W/m2 or W. Practically, it originates from a temperature differences in a given system. When bulk insulation becomes full of heat it allows that heat to easily transfer yet still holds the stored heat from the day. This heat is released at night into your building causing it to be much hotter at night than outside generally. At night, after hot days, the urban infrared heat continues transferring into the building..

Unlike traditional insulation materials which have constant thermal resistance and eventually hit heat flux, the ‘effective’ thermal resistance of cool roof coatings with infrared heat blocking and phase change materials exhibits a dynamic characteristic as weather condition changes with time. Cool roof coatings don’t have ‘resistance’ because heat is unable to load into the coating. Investigating the effect of passive envelope properties of cool roofs for different roof assemblies under four different climates gave and accuracy of estimation of heat flux through roof, an indicator of the roof thermal efficiency, was found to have improved by up to 78% (Zingre, Kumar, Wan, Choa, 2021).

Allowing the solar absorption of infrared “conductive” heat into the building through the roof and walls means that heat will also be transferred internally. Knowing how much heat is allowed to be transferred inside a building assists industry and consumers to better gauge the value of paints and coatings and also helps HVAC (Heating, Ventilation, Air conditioning) contractors better calculate the size of the air conditioning requirements. Conduction through infrared heat and heat load are critical pieces of information for effective, energy efficient and sustainable homes and investments in proper cool roof coatings that give you the U value of how much heat they let through as a true heat measure.

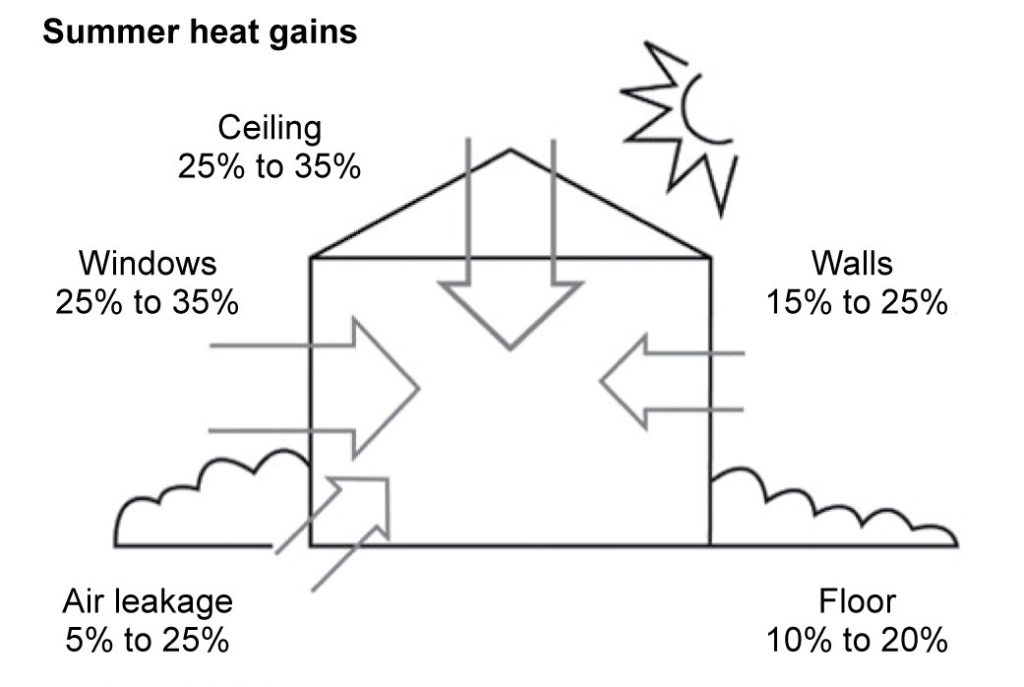

YourHome.gov.au (image above) doesn’t consider cool roofs as part of an energy efficient home. They state: Insulation acts as a barrier to heat flow (this is not accurate – R values are based on Resistance, once heat flux is achieved the insulation is minimised) and is essential for keeping your home warm in winter and cool in summer. A well-insulated and well-designed home provides year-round comfort, cutting cooling and heating bills, and reducing greenhouse gas emissions (YourHome, n.d.).

Ironically many homes have their ducted air conditioning in the roof space that is being smashed by the solar heat that has transferred through. A grey roof on a 24°C day can reach over 45°C and load heat into the R 1 ducting of the air conditioning unit. This makes the unit work hard, consume more electricity and increases CO2 emissions.

Increasing roof surface radiative properties i.e., solar reflectance alone has advantages during both daytime and nighttime with daily integrated-heat gain reduction by 60–68%. Whereas increasing the other thermo-physical properties of the envelope i.e., adding insulation or thermal mass (with a layer of phase change material-modified skim coat) has advantage only during daytime, but penalty during nighttime for the hot climates (Zingre, Kumar, Wan, Choa, 2021). That penalty is stored heat load from the day.

Considering YourHome.gov.au state 25-35% of the heat enters through the ceiling then preventing solar absorption at the roof or building’s exterior envelope, the largest thermal mass directly facing the sun is logical and lighter the roof colour the better. Coatings that block infrared heat is the ultimate standard we should seek. This means understanding paints and coatings which offer a U value as evidence of the amount of heat transfer in W/m2/k or Total Solar Reflectance is the only appropriate measurement to manage solar heat absorption. SRI and reflectivity don’t give that basic information or a solution.

Point 6: Heat load, heat transfer and total heat protection are crucial for energy efficiency

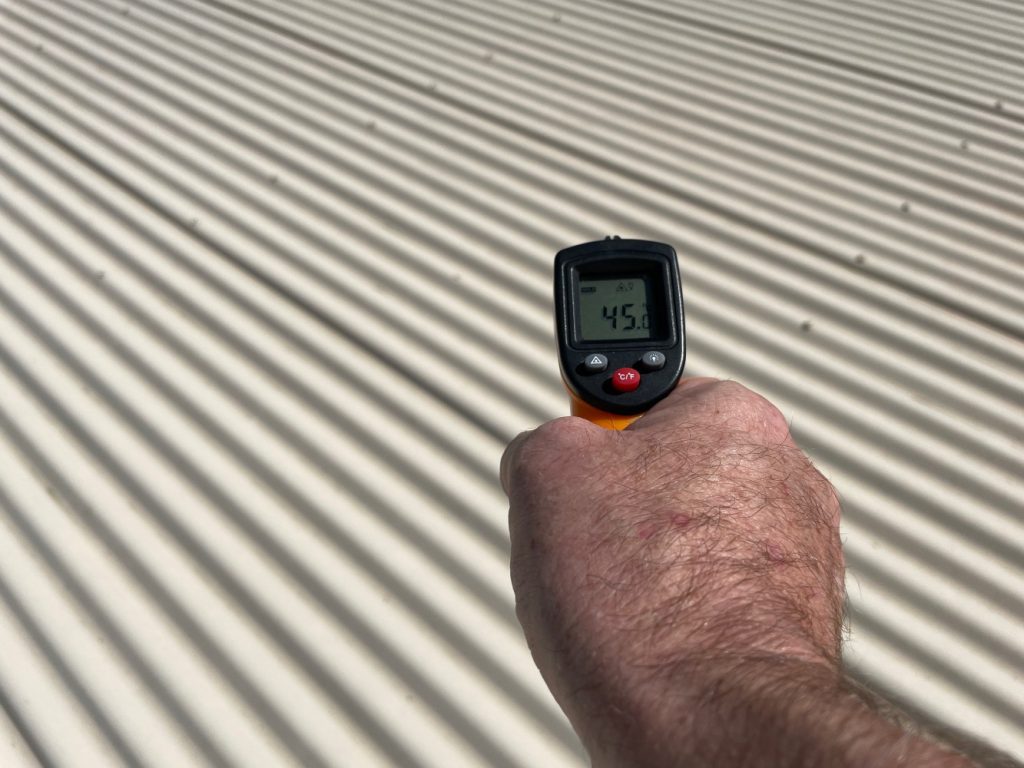

The Infrared Thermometers Reference

Another common strategy used is to show external roof temperature readings on a roof is with an infrared thermometer gun. This is used to read the new cool roof and sometimes the old uncoated roof as a comparison. Anyone could easily paint a roof with white paint as compared with a dark roof and show the external temperature difference drop with these thermometers as we did with the car example.

As we’ve seen, dark colours absorb more heat and hold that heat, so naturally a white roof will be cooler when you take a temperature reading, this doesn’t mean all the heat is being prevented at the building’s envelope from being transferred inside. We’ve also seen images where the side by side are on different roofs, different times of the day and different seasons. no truth or accuracy as a comparison.

Point 7: A key metric should be what’s the underside temperature saving and energy transferred into the building.

The reading above is a light coloured Surfmist® roof showing 45°C on a 25°C day. The infrared heat is being loaded into the metal and showing a higher temperature but what you can’t see is the heat being transferred into the building below. While the roof colour isn’t white it is still 20°C above ambient so not that cool. This works on any surface as we showed with the cars above. White will always be a lower temperature, however it doesn’t tell you how much infrared heat has transferred through the substrate into the building below.

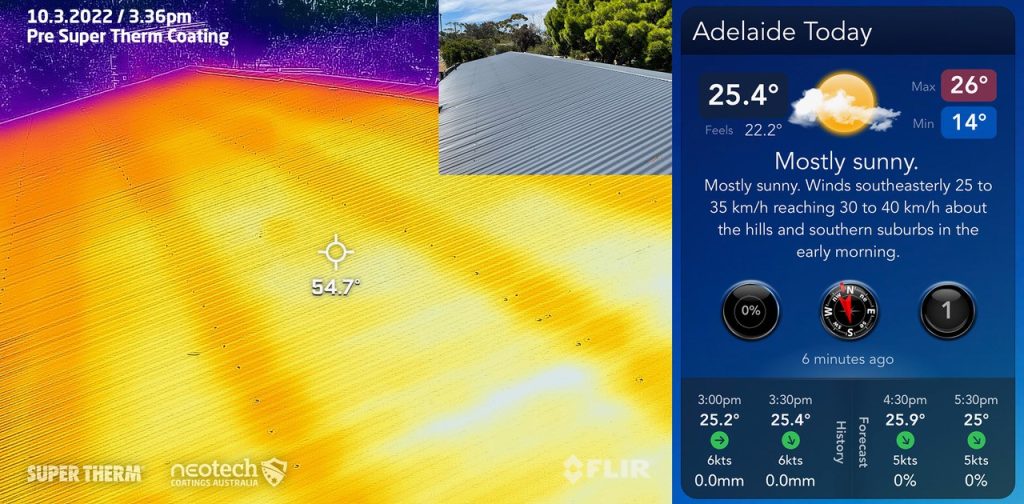

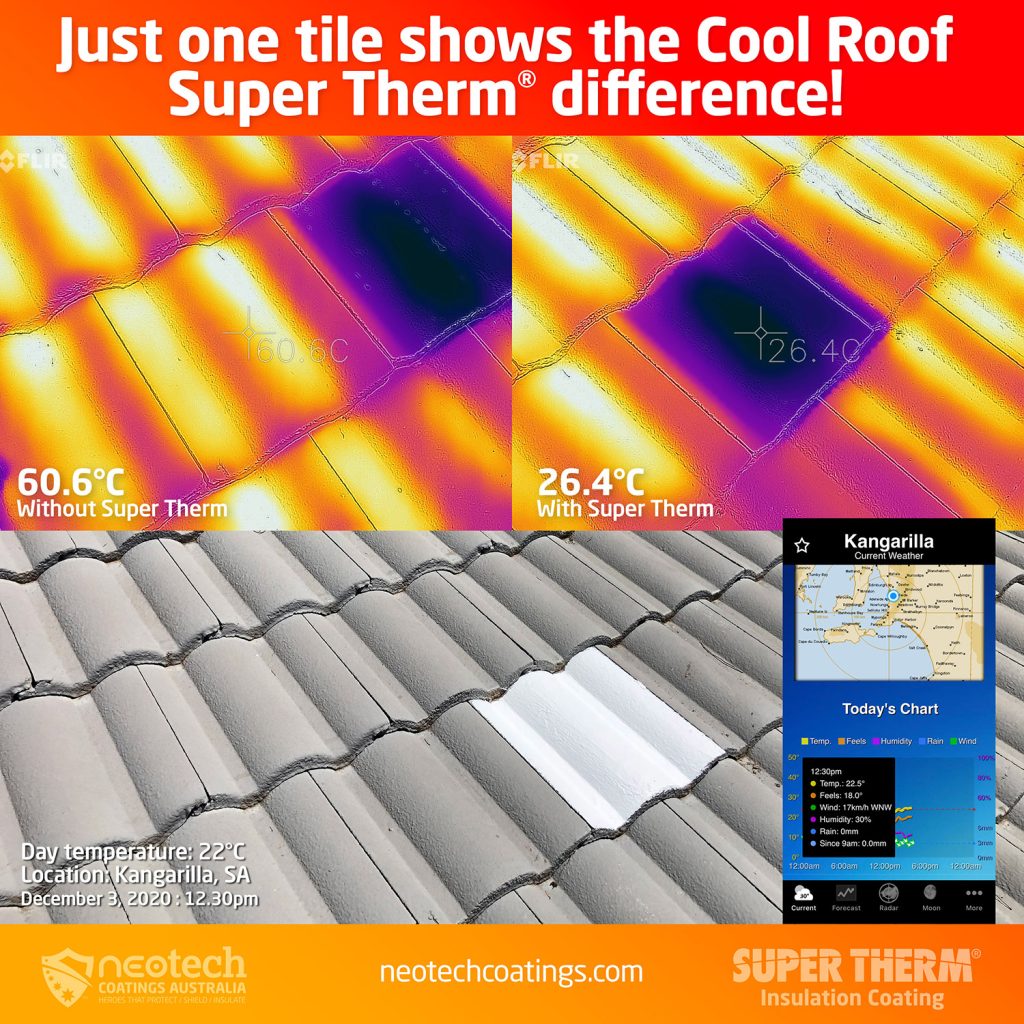

City of Adelaide Cool Roof Trial

The City of Adelaide with the University of Adelaide are undertaking a cool roof trial (NEOtech Coatings, 2022) with Super Therm® that also blocks 99.5% of infrared heat. The netball clubrooms had a Deep Ocean Colorbond® roof originally. On a 25°C day the external roof temperature was 53°C. The heat generated from this roof loads into the metal and transfers into the building, pushing up the need for air conditioning use and making the rooms uncomfortable.

See the City of Adelaide Trial

After application with Super Therm® on a 27° day, the netball clubrooms roof was a very cool 24°C compared with previous high of 53°C on the uncoated roof. This 225% improvement means it was much cooler inside the building as there was a tiny amount of heat loading into the roof space and traditional insulation. The end game is to demonstrate how much total solar heat can be blocked; that is, not loading into the building which means less demand on air conditioning, less running costs and less heat absorbed in building materials which impacts the urban heat island effect.

When hot, the infrared heat is the invisible radiant heat band that needs to be blocked.

Interesting to note on the image above the foliage is hotter than the roof. Field data will be collected through to March 2023 for both internal and external temperatures along with ambient both before and after application.

GR Keech from New Energy Thinking explains it well. The reality is that all solar radiation is converted to heat when absorbed by a material, unless the material is a solar cell. As it relates to the spectrum diagram above, the total area depicted in red is watts per square metre of solar radiation. There is about the same amount of that solar radiation in the visible band as in the near infra-red band (New Energy Thinking, 2021).

The apparent colour of an object tells you what it will absorb in the visible band, but not in the infrared band.

A simple experiment with a thermal imaging camera captures this direct solar heating of black materials compared with white materials. In this experiment below, socks were used as the material, and the difference in solar heating could easily be seen. On a 30°C day, the white sock is 35.4°C and the black sock is 46.9°C (New Energy Thinking, 2021). The black sock is 31% hotter…imagine a steel or concrete roof with density.

The question should be, how much heat is being transferred through the surface into the building?

International Cool Roof Councils

The USA and Europe utilise SRI as the rating system for cool roofs. This is unfortunate, as you can see, SRI isn’t an effective measurement for total solar heat absorption, therefore cannot give accurate results for sustainability and performance inside buildings.

Cool Roof Rating Council – USA

SRI is the base standard of the USA’s largest cool roof rating council. When your product application with the initial test results has been reviewed and approved by the CRRC, the initial radiative property ratings (solar reflectance, thermal emittance, and SRI) for the product will be automatically listed on the Rated Roof Products Directory. The aged radiative property ratings will be listed as “pending” until the three-year weathering process and aged testing is completed (Cool Roof Rating Council, n.d.).

European Cool Roofs Council

The European Cool Roof Council (ECRC) operates a rating program for the radiative properties (i.e. the solar reflectance and the infrared emittance) of roofing products. The purpose of the ECRC product rating program is to provide a uniform and credible system for rating and reporting the radiative properties of roofing materials. In the framework of this program, manufacturers and sellers have the opportunity to label roofing products with the measured values of their Initial Radiative Properties. The ECRC product rating program does not specify minimum or target values for any radiative property (European Cool Roofs Council, n.d.).

Both these council’s while utilising SRI as their base rating program doesn’t mean it’s the best or most effective standard to use. Just easier! The framework built around SRI is significant because it’s had traction since 1998, however SRI isn’t the most effective way for measuring thermal efficiency inside buildings therefore it is letting down consumers and genuine energy efficiency opportunities.

The University of Melbourne undertook a “Cool Roofs: City of Melbourne Research Report” in September, 2011. They stated “The SRI method is not used in this study as it is expensive and more difficult to determine the effect of the solar reflectance and thermal emittance individually for the products tested” (University of Melbourne, 2011). Meaning they were interested in the actual heat load and solar absorption and determined that SRI brought no real value to these results because it was difficult to assess for their study.

Solar reflectance isn’t the most important characteristic of a cool roofing coating to achieve the highest energy savings during warmer months. Solar absorption is the best measure. The US Energy Authority showed significant energy reduction of 20-50% (NEOtech Coatings, 2022) with Super Therm® Insulation Ceramics Coating with relatively simple measures (results may vary in different locations and climates). They were all measured based on energy savings inside the substrate and no reference to SRI.

Case Study to Measure Carbon Emissions and Energy Reduction

SRI advocates talk about CO2 reduction in generalised statements but there’s no way that can ever be measured in their standard. The actual energy savings from SRI can’t be quantified…ever! Solar absorption allows for measurement of W/m2/K, BTU’s (British Thermal Units) in heat transfer which can be convert into carbon emission and energy savings. Why BTU? BTU’s are used globally as an energy or heat content can be used to compare energy sources or fuels on an equal basis. Fuels can be converted from physical units of measure (such as weight or volume) to a common unit of measurement of the energy or heat content. The U.S. Energy Information Administration (EIA) uses BTU as a unit of energy content (U.S. Energy Information Administration (EIA), 2022).

In 2003 a case study was conducted on Super Therm® Insulation Thermal Coating, applied to a residential home roofing system in Florida in accordance with the State of Florida Energy Office / Energy Conservation Assistance Programs Designation: ECAP-CUL-1-99. Test Method for Comparing Utility Loads in Standard Constructed Buildings (NEOtech Coatings, 2022).

The objective of the case study was to determine the actual impact on a residential home, after the implementation of a cool roof Energy Conservation Retrofit and verify the reduced utility loads. The focus of the case study was to provide a comparison to known standards for all parties interested in using energy related products to displaced conventional utility load costs. This case study addressed the energy consumption properties of the equipment and structural envelope tested.

Predicated on historically accepted Florida Air Conditioning building component load data and the square footage of the project surveyed, the estimated air conditioning load savings from the Super Therm® retrofit was approximately 11.09 tons of load per 24 hour period (NEOtech Coatings, 2022). Final outcomes for energy reduction and CO2 reduction were significant:

- Standard Roof load with no insulation coating: 226,000 BTU’s per hour

- Super Therm Roof load: 93,500 BTU’s per hour

- Savings from Super Therm solar heat block coating: 132,500 BTU’s per hour or 240%

- Reduced environmental impact 66 pounds of power plant emissions per hour

The calculation is based on the ASHRAE Formula: (Original Temp. X Difference / 24 = tons of energy X 12,000 BTU per ton = BTU Savings. Change BTU into KW to find COST SAVINGS per hour / day / week / month / year. (1 BTU = .293 Watt)

132,500 X .293 Watt = 38,822 Watts / 1000 = 38.82 KW/hr in Australia (34 cents K/W*) or $13.19 per hour savings.

Point 7: Only solar absorption gives you accurate energy data to make energy efficient decisions regarding cool roof and energy assessments.

Now these are quantifiable and measured energy results from total solar transmittance, BTU’s and consequently CO2 reduction which are unattainable results from SRI measurements. Cool roof coatings can be measured, quantified and valid if tested correctly. The report summary stated: On behalf of a United States Energy Authority, The State of Florida Energy Office and the United States Environmental Protection Agency, let me thank you for your efforts in developing an affordable product that obviously can be instrumental in Conserving Energy.

If governments and industry are serious about carbon emission reduction and energy savings, the urgency to implement correct standards and measurements that actually track and measure carbon emissions reductions should be fundamental.

Future of Cool Roofs in Australia: Technical and Commercial Prospects

The High Performance Architecture research group of The University of New South Wales (UNSW) has undertaken a study on Cool Roofs in Australia in 2022. They aimed to understand the applicability and cost-benefit of using cool roof technology on buildings in Australia and any barriers to adoption (UNSW, n.d.). While this report has merit it doesn’t consider or even reference TSR or U values as the primary objective for thermal transfer. The UNSW video on a cool roof report proposal for the Department of Industry, Science, Energy and Resources talking about the potential impacts of cool roofs on cities across Australia regrettably has a final recommendation for SRI and not solar absorption.

Cool roof industry professionals making comments in the video reference utilise Solar Absorption (SA) or Total Solar Reflectance (TSR) as key metrics to promote to customers the actual heat load into buildings. These are experts with skin in the game and many years experience with cool roof coatings. It’s not based just on computer simulations, modelling or theories.

The suggestion for SRI as the Cool Roof standard is to align with the USA and Europe. We advocate there’s a much better, energy efficient and quality standards that can be implemented. Because something is easy, or being done elsewhere or considered ‘norm’ doesn’t mean it’s effective and the implementation of SRI wouldn’t be world leading decision. This would be a mistake to utilise SRI as a way to measure cool roofs in Australia.

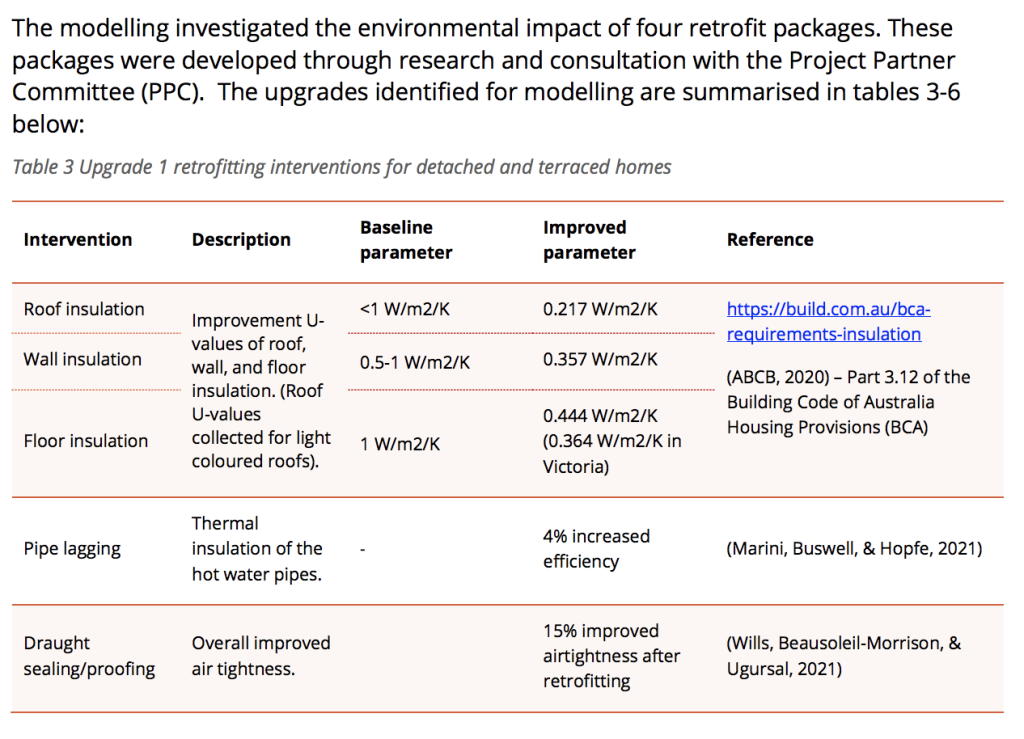

Interestingly in the RACE for 2030: Pathways to scale: Retrofitting One Million+ homes report by the same Department of Industry, Science, Energy and Resources on page 23 recommended Roof U values collected for light colour roofs of 0.217 W/m2/K (Department of Industry, Science, Energy and Resources, 2021) yet the recommendation by the UNSW is for solar reflectance; not solar absorption which isn’t a high performance recommendation.

Image: (Department of Industry, Science, Energy and Resources, 2021).

While the UNSW has made a recommendation only for SRI, the industry and governments should see the benefit of U values and solar absorption. U values can be 100% verified against kW power consumption in a building which can be measured against energy use, air conditioning use and even carbon emissions and heat transfer. SRI can’t do that! Measuring the actual energy transfer will be the only way the building code can be modified for proven sustainable results and not speculation of relative results.

Point 8: SRI can’t measure carbon emissions, energy use, energy consumption or even help with installing appropriate sized air conditioners

Hopefully you’re starting to understand why SRI isn’t an effective cool roof standard. The problem is, if we continue using the wrong assumptions we’ll continue having the same issues and not solve our challenges.

SRI as a standard is more average than efficient or effective

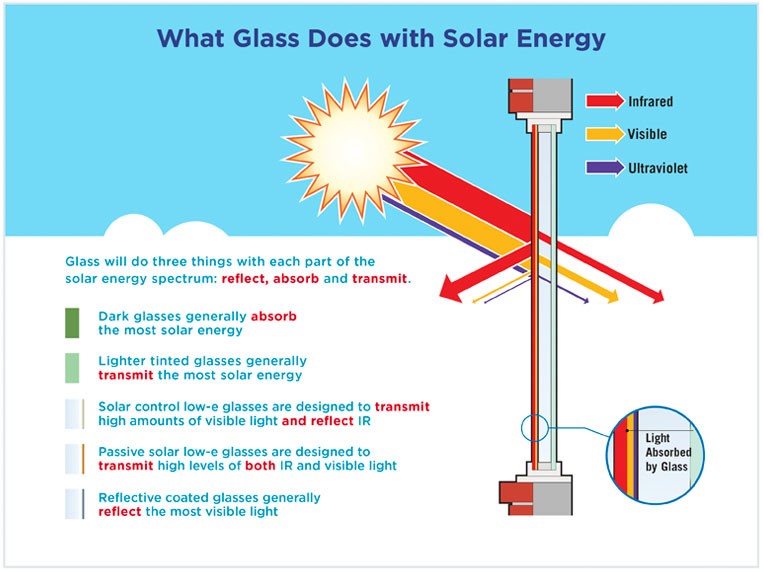

U Values and Solar Heat Gain in the Glass Industry

U value is the measure of the insulating capacity of the glass. This represents how quickly heat from hot air (not direct sunlight) will pass through the glass. The lower the U value the better the insulation (Viridian, n.d.). Ultimately once the solar heat hits the roof it becomes about conductivity and not reflectivity.

A key point by YourHome.gov.au is for glazing: The thermal performance of a window, door, or skylight depends on how well the glass and frame conduct heat (conduction or U value) and how well the glass and frame transmit heat from direct sunlight (the solar heat gain coefficient or SHGC) (YourHome, n.d.).

This should be a similar standard of measure that cool roof coatings can adopt. It is about how quickly and how much heat passes through the coating and material to the inside of the building. The U value of coatings refers to the heat gain through building substrates, this is calculated at the rate of heat gain or loss per metre square of material. When looking for better performing coatings the lower the U value the better the product is at preventing heat gain or loss.

A lower U value means the less heat that is being gained preventing unwanted heat flow and cooler buildings and energy savings.

The Solar Heat Gain Coefficient (SHGC) as an integral part of choosing thermally performing in the glass industry. This refers to the amount of radiant solar heat that is absorbed or blocked by the glazing. Both the U and SHGC values are greatly considered in rating projects in Section J of the NCC. Section J was part of the recommendation in the UNSW recommendations so moving from SRI to U Values for Section J Energy Efficiency makes sense and relates absolutely to energy efficiency.

The number given for the SHGC is the fraction or percentage of heat released inwards through the glazing therefore. If you want to gain heat through windows in colder climates the higher SHGC value should be chosen, whereas if the aim is to reduce the amount of solar energy entering the house, a lower SHGC is preferable (Bonnefin, 2016).

In hot parts of the world, you want a low SHGC. If you also want an effective (lower) U value to stop the heat transferring into the building (and to stop the cool temperatures moving out of the building) utilising the SHGC and U values makes much more sense than SRI.

Point 9: U values are recommended by Section J of the NCC and aligned with stands set for glazing by YourGov.gov.au. This will help with better energy efficient building decisions in future.

YourHome.gov.au and their U value formula

YourHome.gov.au has the answer and the formula for U values for the glazing industry. From their website:

Conduction is how readily a material conducts heat. This is known as the U value. The U value for windows (expressed as Uw), describes the conduction of the whole window (glass and frame together). The lower the U value, the greater a window’s resistance to heat flow and the better its insulating value.

U value, known officially as thermal transmittance. This is more of an engineering term used to designate the thermal performance of a system as opposed to a homogeneous material. The ASTM C168 definition is as follows:

Transmittance, thermal, n: the heat transmission in unit time through unit area of a material construction and the boundary air films, induced by unit temperature difference between the environments on each side.

The amount of heat conducted through a glazed unit (in watts; W) is calculated as Uw × T × A:

- the U value (Uw)

- multiplied by the number of degrees difference in air temperature on each side (T)

- multiplied by the area of the glazing unit (A).

For example, if your home has 70m2 of glazing with aluminium frames and clear glass with a U value of 6.2W/m2 °C, on a winter’s night when it is 15°C colder outside compared with indoors, the heat loss through the windows would be:

6.2 × 15 × 70 = 6510W

That is equivalent to the total heat output of a large room gas heater or a 6.5kW room air-conditioner running at full capacity.

If you choose a window with half the U value (3.1W/m2 °C) (for example, double glazing with an argon-filled gap and less-conductive frames), you can halve the heat loss:

3.1 × 15 × 70 = 3255W

If YourHome.gov.au is able to implement a formula and strategy for U values in the glazing industry then a model can be utilised for cool roofing. In essence, the cool roof product can be applied to standard new galvanised sheeting as the base substrate and tested at ASTM C1363 rather than SRI which gives zero solar heat absorption values. While they do advocate for a ‘system’ over a single product, coatings and paints could utilise galvanised, zincalume and concrete tiles as the base substrate to measure the U value as part of the ‘system’.

Image: Research the RTAA commissioned, performed by the University of Newcastle, found that light coloured tiles yielded “energy savings between 25-36 per cent compared to dark coloured tiles” (Jewell, 2014). Going the extra mile and reducing heat load and watts transferred, Super Therm® was applied to a tiled roof and it was able to block the total solar heat and keep tiles cool, therefore reduce the heat load into the home.

In the ASTM C1363 test, the assembly is placed in a wall between the warm and cold rooms. Temperatures are maintained in the two rooms until steady-state conditions have been met for temperature on both sides and energy input to the warm side. The heat flow through the assembly is measured to determine the U factor and/or R value of the assembly. End Result: The thermal transmittance (U factor) and/or thermal resistance (R value) of the assembly is determined. These can be used to determine energy losses through assemblies and the impact on overall building energy usage.

Point 10: U values are simple to calculate and give the advantage of watts of energy transfer that can measure energy efficiency of products and their direct impact on buildings unlike SRI.

So why use SRI?…because it’s easy!

Yes, because it’s easy to measure! Not effective, just easy…and this is a low benchmark of significant energy efficient decisions and investments regarding cool roofs that will effect millions of Australians.

It’s only covering optical and not absorption

We have an opportunity to introduce a U values (like glazing ratings) to understand the actual total solar heat gain and heat load and set a new and efficiency benchmark worldwide for cool roof ratings. This means we can better know the actual thermal properties and net benefits of heat transfer into the building from cool roof paints and coatings. This can then be referenced as an absolute, exact and beneficial investment for consumers. Not the misguided truth about how white paint should be.

The end game is to know how much heat is being transferring rather than just how white and shiny the coating is and it’s emissivity. Infrared conductive solar heat absorption is the “X” factor SRI doesn’t measure for a true thermal value.

SRI isn’t worth any real value as a measurement

Other features and benefits the cool roof standards could offer:

- Fire protection rating

- Mould, mildew and moss resistance

- Sound reduction

- Warranties for peeling, flaking and cracking

- Standards that all products display the ASTM testing and SDS sheets

- U values as W/m2/K

- Number of coats application

- Condensation control

- Date since manufacture

- Country of manufacture

Cool roof industry professionals utilise Solar Absorption (SA) or Total Solar Reflectance (TSR) as key metrics to promote to customers the actual heat load into buildings. TSR takes into consideration along with the average reflectivity at three different wavelength of Infrared, Visual and UV of the solar spectrum and thermal emittance of paints and coatings. The rest are just try to make the whitest paint.

The sole focus on SRI as a measurement of heat can attract misrepresented products:

- Makes manufacturers and researchers race to produce the whitest of white paints, not true thermal barriers

- Allows for ambiguity and white washing of products not based on true thermal performance

- The brightest white paint may still not have good emissivity or high Total Solar Reflectance value that blocks Infrared heat

- Reduces the true solar thermal efficiency and energy solutions

- Doesn’t allow energy efficient experts and architects to effectively calculate the efficiency of cool roofs and impacts and benefits on buildings, costs, environmental benefits and relationship to building thermal efficiency and investment

- 3 years longevity testing doesn’t accurately reflect expected 10 year+ lifespan and investment

- May only last 5 years then the cost to reapply in cleaning, preparation, product and application

- No clarification regarding results for visual, UV and infrared for consumer awareness and comparison

- No W/m2/K rating covering internal heat energy transfer

- U values give better guide to heat transfer and solar energy ratings

Summary

There’s a myriad of reasons why Australia shouldn’t consider SRI as the benchmark for cool roofs.

- No solar absorption value

- No U value to measure and calculate energy costs

- No way to measure CO2 emissions

- No contribution to understanding thermal efficiency as an absolute measurement

- Misrepresents on how white a paint is and not the actual heat efficiency

- No way to truly measure thermal efficiency for architects or builders regarding heat gain and W/m2/K of energy transfer

As we’re seeing overseas, Australia is facing serious climate change, significant heat threats and increased deaths are continuing; it’s astounding we’re looking to the easiest option of SRI, not the most effective for energy efficiency and sustainability. We have an opportunity to introduce a U values (like glazing ratings), like recommended by YourHome.gov.au and Department of Industry, Science, Energy and Resources, 2021 to understand the actual heat transfer and heat load and set a new and efficient benchmark worldwide for cool roof ratings.

Australia’s leading Energy Efficiency Home Ratings (NatHERS, n.d.) system NatHERS doesn’t mention cool roofs as an energy efficiency standard for homes because there is no standard they can measure energy efficiency against. SRI isn’t a calculable, absolute standard. Utilising a value of absolute measurement means we can better know the actual thermal properties and net benefits of heat transfer into the building from cool roof materials, paints and coatings. This can then be referenced as an exact and beneficial investment by our community.

This is Australia’s building and energy efficiency blindspot

The Solar Reflective Index is determined through solar reflectivity and emissivity…it doesn’t add up or connect to the purpose of measured true thermal and energy efficiency and performance in buildings, well being or cost savings.

The end game is to know how much heat there is transferring rather than just how white the coating is and it’s emissivity. Infrared conductive heat is the “X” factor SRI doesn’t measure effectively as an optical measurement for a true thermal value. The amount of heat absorption factor is being completely ignored with SRI by researchers, academia and industry therefore in the bigger picture our society doesn’t have the knowledge and is being mislead on what a true value should be.

In the end; SRI isn’t worth any real future value as a standard for energy efficiency

Shane Strudwick, NEOtech Coatings Australia

KW Reduction from Super Therm® = Actual Dollars

References

ACCC. (2016, November 3). Dulux to pay $400,000 for misleading cooling paint claims. Australian Competition and Consumer Commission. https://www.accc.gov.au/media-release/dulux-to-pay-400000-for-misleading-cooling-paint-claims

Altan, H., Alshikh, Z., Belpoliti, V., Ki Kim, Y., Said, Z., & Al-chaderchi, M. (2019, February 5). Experimental study of the impact of cool roof on solar PV electricity generations on building rooftops in Sharjah, UAE. OUP Academic. https://academic.oup.com/ijlct/article/14/2/267/5307064

Berkeley Labs. (n.d.). SRI calculator. HEAT ISLAND. Retrieved August 1, 2022, from https://heatisland.lbl.gov/resources/sri-calculator

Bonnefin, J. (2016, August 19). U and R values & energy rating: What do they mean? Certified Energy | ESD Consultancy in Sydney, Melbourne & Brisbane. https://www.certifiedenergy.com.au/blog/u-r-values-energy-rating

BYJUS. (2020, April 6). Heat Conduction Formula. https://byjus.com/heat-conduction-formula/

Continuing Education Center. (2011, May). Cool roofs for hot projects. CE Center Home. https://continuingeducation.bnpmedia.com/courses/cool-roof-rating-council/cool-roofs-for-hot-projects/2/

Cool Roof Rating Council.Retrieved August 1, 2022, from https://coolroofs.org/

Corrosionpedia. (2016, May 17). What is a solar reflective index? – Definition from Corrosionpedia. https://www.corrosionpedia.com/definition/5226/solar-reflective-index-sri

Department of Industry, Science, Energy and Resources. (2021, December). Pathways to scale: Retrofitting One Million+ homes. RACE for 2030. https://www.racefor2030.com.au/wp-content/uploads/2021/12/One-Million-Homes_Final-Report-9.12.21.pdf

Designing Buildings. (2021, July 30). Solar Reflectance Index in the built environment. https://www.designingbuildings.co.uk/wiki/Solar_Reflectance_Index_in_the_built_environment

Engineering ToolBox. (n.d.). Emissivity coefficients common products. The Engineering ToolBox. Retrieved August 1, 2022, from https://www.engineeringtoolbox.com/emissivity-coefficients-d_447.html

European Cool Roofs Council.Retrieved August 1, 2022, from https://coolroofcouncil.eu/

Glorfeld, J. (2019, April 2). Cool roofs reduce urban heat; green ones, not so much. Cosmos. https://cosmosmagazine.com/earth/climate/cool-roofs-reduce-urban-heat-green-ones-not-so-much/

Hashem, A., & Ronnen, L. (2008, July 11). Evolution of cool-roof standards in the United States (Journal article). OSTI.GOV. https://www.osti.gov/biblio/935717

Jewell, C. (2014, March 13). The Fifth Estate | Cool roofs versus dark roofs. https://energycut.com.au/business/wp-content/uploads/2015/02/The-Fifth-Estate-Cool-Roofs-Versus-Dark-Roofs.pdf

King, R. (2021, June 7). Solar panels only have a lifespan of 10-25 years. So what happens to them once they expire? ABC (Australian Broadcasting Corporation). https://www.abc.net.au/news/2021-06-06/what-happens-to-solar-panels-after-their-useful-life-is-over/100193244

Kondo, Y., & Musashi Inst. of Tech. (2006). Current State and Future Prospects of Current State and Future Prospects of Cool Roof in Japan Cool Roof in Japan. https://www.coolrooftoolkit.org/wp-content/uploads/2012/04/Cool-Roofs-in-Japan-Kondoh.pdf

Mauer, Milan & Kalenda, Petr & Honner, Milan & Vacikova, Petra. (2012). Composite Fillers and their Influence on Emissivity. Journal of Physics and Chemistry of Solids. 73. 1550–1555. 10.1016/j.jpcs.2011.11.015.

Mazahernasab, R. (2013, June 24). Spectrophotometry : Instruments & applications. https://www.slideshare.net/rey216/spect

Meaney, A. (2020, June 8). HVAC load calculation: Remember these three important things. Snips Magazine | Sheet Metal, HVAC, IAQ & Metal Roofing | SNIPS. https://www.snipsmag.com/articles/94249-hvac-load-calculation-remember-these-three-important-things

Muscio, A. (2018, February 15). The solar reflectance index as a tool to forecast the heat released to the urban environment: Potentiality and assessment issues. MDPI. https://www.mdpi.com/2225-1154/6/1/12/htm

NatHERS.Retrieved August 1, 2022, from https://www.nathers.gov.au/

NEOtech Coatings. (2022, July 12). Heat blocking, reflectivity, emissivity and emittance…the facts! NEOtech Coatings Australia | Leading Insulation and Protective Coatings. https://neotechcoatings.com/heat-blocking-reflectivity-emissivity-and-emittance-the-facts/

NEOtech Coatings. (2022, April 7). The super cool roof guide. NEOtech Coatings Australia | Leading Insulation and Protective Coatings. https://neotechcoatings.com/cool-roof-guide/

NEOtech Coatings. (2022, July 8). Super therm® energy savings cool ceramic coating. NEOtech Coatings Australia | Leading Insulation and Protective Coatings. https://neotechcoatings.com/coating-products/super-therm-solar-heat-block-coating/

NEOtech Coatings. (2022, June 1). Super Therm® energy industry test reports. NEOtech Coatings Australia | Leading Insulation and Protective Coatings. https://neotechcoatings.com/super-therm-energy-star-savings/super-therm-usa-energy-authority-reports/

NEOtech Coatings. (2022, July 14). Different heat reduction coating compounds compared. https://neotechcoatings.com/different-heat-reduction-coating-compounds-compared/#bariumsulfate

NEOtech Coatings. (2022, July 13). City of Adelaide cool roof trial 2022-2023. https://neotechcoatings.com/projects/city-of-adelaide-cool-roof-trial-2022-2023/

New Energy Thinking. (2021, December 1). Debunking a myth about solar radiation. https://newenergythinking.com/2021/11/26/debunking-a-myth-about-solar-radiation/

OTM Solutions. (2021, December 17). Online solar reflectance index (SRI) calculator – OTM solutions Pte Ltd. https://www.otm.sg/sri-calculator

Pal, S., Contaldi, V., Licciulli, A., & Marzo, F. (2016, October). Self-Cleaning Mineral Paint for Application in Architectural Heritage. ResearchGate. https://www.researchgate.net/figure/Total-solar-reflectance-TSR-along-with-the-average-reflectivity-at-three-different_tbl1_309277289

Pockett, J. (2010, September). Heat Reflecting Paints and a Review of Their Advertising Material. ResearchGate. https://www.researchgate.net/publication/267640159_Heat_Reflecting_Paints_and_a_Review_of_Their_Advertising_Material

Razzhigaeva, N. (2022, June 15). Are cool roofs the future for Australian cities? UNSW Newsroom. https://newsroom.unsw.edu.au/news/art-architecture-design/are-cool-roofs-future-australian-cities

Sparkes, M. (2021, April 15). Whitest paint ever reflects 98 per cent of light and could cool homes. New Scientist. https://www.newscientist.com/article/2274809-whitest-paint-ever-reflects-98-per-cent-of-light-and-could-cool-homes/

Stop These Things. (2020, October 4). Lingering legacy: Millions of toxic solar panels that can’t be recycled destined for landfills. https://stopthesethings.com/2020/10/10/lingering-legacy-millions-of-toxic-solar-panels-that-cant-be-recycled-destined-for-landfills/

U.S. Energy Information Administration (EIA). (2022, June 30). British thermal units (Btu). https://www.eia.gov/energyexplained/units-and-calculators/british-thermal-units.php

University of Melbourne. (2011, September). Cool Roofs: City of Melbourne Research Report. https://www.melbourne.vic.gov.au/SiteCollectionDocuments/cool-roofs-report.pdf

UNSW. (n.d.). Study on the cool roofs mitigation potential in Australia. Retrieved August 1, 2022, from https://www.unsw.edu.au/arts-design-architecture/our-schools/built-environment/our-research/clusters-groups/high-performance-architecture/projects/study-on-the-cool-roofs-mitigation-potential-in-australia

Van Lith, A. P., Entrop, A. G., & M Halman, J. I. (2018, March 23). Assessment of the thermal performance of holistic flat roof systems of industrial buildings. https://www.goldenlightpublish.com/dosyalar/baski/JCEMI_2018_2.pdf

Viridian. (n.d.). What is the difference between U value and solar heat gain coefficient? Retrieved August 1, 2022, from https://www.viridianglass.com/resources/faqs/energy/what-is-the-difference-between-u-value-and-solar-heat-gain-coefficient

YourHome. (n.d.). Insulation. Retrieved August 1, 2022, from https://www.yourhome.gov.au/passive-design/insulation

YourHome. (n.d.). Glazing. Retrieved August 1, 2022, from https://www.yourhome.gov.au/passive-design/glazing

Zingre, K.T.; Kiran Kumar, D.E.V.S.; Wan, M.P.; Chao, C.Y.H. (2021, September 27) Effective R-value approach to comprehend the essence of integrated opaque passive substrate properties. https://www.sciencedirect.com/science/article/abs/pii/S2352710221007233