Super Therm® – The Original Ceramics Thermal Insulation Coating since 1989

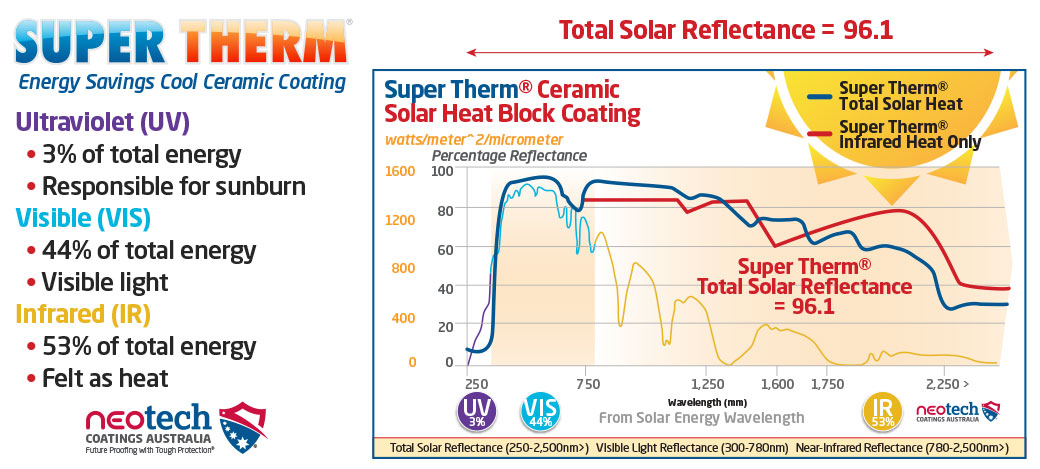

Super Therm® is the world’s most advanced multi-ceramic, closed-cell, thin-film solar insulation coating – engineered with NASA from 1989 to block heat, slash energy use and protect any surface it covers. With six years of development it integrates four specialised ceramics to block 96.1% of total solar heat, including an unmatched 99% of infrared radiation blocked. Its utilised by some of the world’s largest multi-companies, on some of the world’s iconic infrastructure as well as day-to-day solutions to solve heat load challenges.

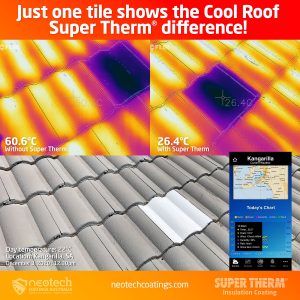

Super Therm® blocks solar heat; keeping surfaces cool

Like the tiles as a heat shield on the space shuttle, Super Therm® blocks the sun’s heat at the surface before it ever enters the building. It provides high reflectivity, high emissivity (how surfaces release heat) and low diffusivity (how surfaces absorb and load heat) – a level of science and physics no standard “reflective paint” can match and other coatings only dream they can achieve because it’s able to block infrared heat.

Once applied, it transforms roofs, walls or any surface into a powerful heat-repelling substrate, equivalent to being under a shady tree, all with a coating just 0.25mm thin. The result? Dramatic energy savings and heat blocking. This easy to apply coating creates safer, cooler environments, lowers emissions and creates longer-lasting asset protection. Super Therm® is ISO rated and is the most extensively independent test insulation coatings globally where it consistently delivers real-world results that outperform expectations, competitors and other insulation materials when all things are equal.

Super Therm is the thinnest, highest performing insulation coating on the planet

What makes Super Therm® highly unique and effective is its innovative formulation designed with four specialised, advanced ceramic compounds. Unlike coatings that make claims on single ceramic particles, simple hollow spheres or beads with ‘dead air’ claims to slow heat transfer, Super Therm® uses specialised low density, lightweight engineered ceramics designed to actively reflect and block UV, visible and infrared radiation at the surface to reduce heat load transfer across the total solar spectrum.

Like a laser, the targeted solar wave-blocking coating system of Super Therm® prevents heat loading entirely, delivering truly advanced thermal insulation protection and performance without relying on air pockets and thickness because the science is so advanced. Once you experience the cool to touch surface it literally transforms your experience of a coating that insulates.

Super Therm® Key Benefits

- Blocks 96.1% of total solar heat (UV, visible light, and infrared)

- ISO certified coating – quality and consistency

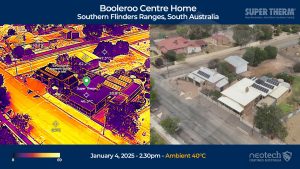

- Reduces internal temperatures by 6°C cooler than ambient in heatwaves

- FEO saves up to 20-50% in energy costs – without running electricity

- Dry film thickness only 0.25 mm – ultra-lightweight and super thin

- 30+ year proven performance in extreme heat and cold globally

- Near zero heat absorbed – stops absorption and re-radiation unlike reflective paints

- Resists water, fire, mould, UV degradation and corrosion

- Developed with NASA – multi-layered and heat neutralising since 1989

- Environmentally friendly – low VOCs, water-based, non-toxic, certified

- Used globally in commercial, industrial and government sectors

Super Therm® Case Studies

Super Therm® Videos | Super Therm® Case Studies

Testimonials

Trusted by Customers Experiences

“Its amazing, our upstairs area just doesn’t have that punch of hot air and any warm/humid air that’s in the house that’s easily handled by air conditioning which now cools the area super quickly. I can’t sing it’s praises highly enough.”

– Richard, Leichhardt, Sydney NSW

“This means that even during the heatwave, these cool roofs do not contribute much to the urban heat island effect.”

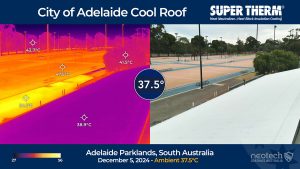

– University of Adelaide/City of Adelaide Cool Roof Trial, 2023

“The ones with the coating stay about one to three degrees from what the exterior ambient temperature is outside,” … “That is phenomenal.”

Doug McMahan, Managing Director for Facilities and Maintenance with the Clark Country Department of Aviation

“…the results by the back of the hand on the coated surface of the roof of the truck, versus the non-coated white duco surfaces anywhere else on the truck are like chalk and cheese.”

Greg O’Grady, Adelaide Hills

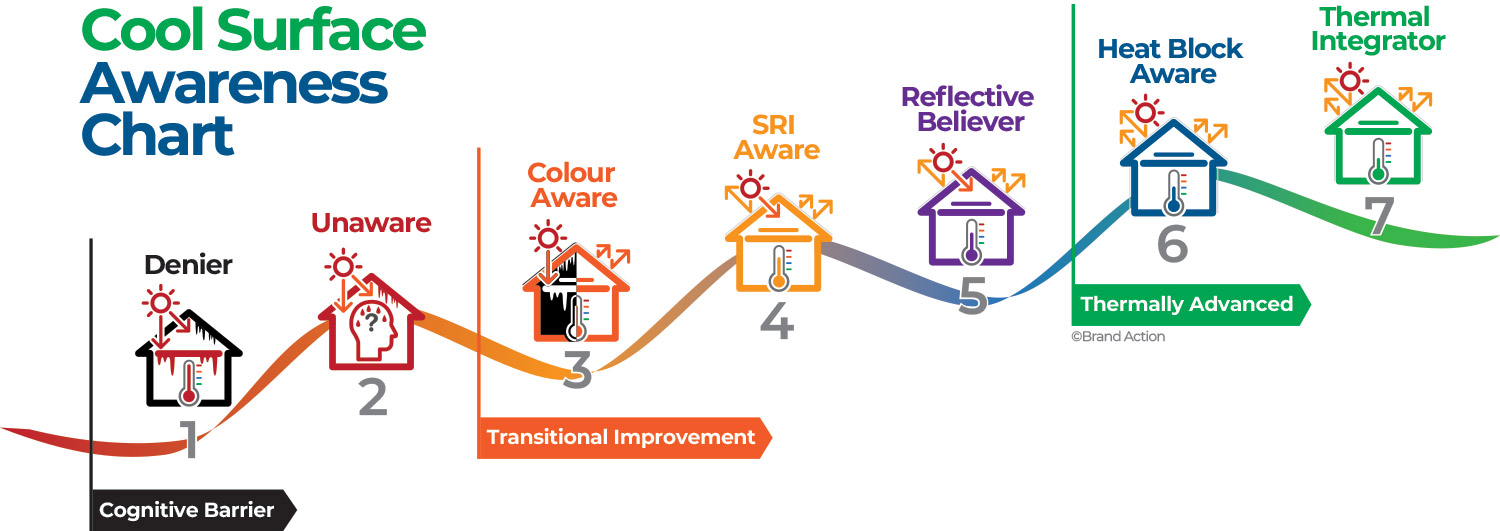

Where do you sit on the Cool Surface Awareness Chart?

As climate demands shift and energy costs rise, understanding how surfaces manage radiation and conductive heat has never been more critical, regardless of the material. This framework outlines the journey from denial of cool surfaces to basic visual assumptions to advanced thermal solutions. From basic colour choice to full heat-blocking technology this Cool Surface Awareness Chart maps the awareness levels shaping modern building performance and energy strategies beyond 2050.

Super Therm® for Large and Small Industries

Super Therm® was originally designed to solve a major heat management challenge, especially in the toughest industrial environments globally. Since the late 1980s, Super Therm® has gone on to become a world leading thermal insulation coating many competitors envy and don’t wish to go head-to-head in testing with. A recent project with the Las Vegas airport showed Super Therm® outperformed the nearest competitor by 6°C.

Additional highly unique Super Therm® Properties

How Super Therm® blocks solar heat

Key Performance Metrics and Science

Heat Block Efficiency – Super Therm® blocks actual heat transfer

Thermal diffusivity is a measure of the rate at which heat disperses throughout an object or body. This is conducted with the ASTM E1269 & E1461-92 test on a metal plate. Super Therm® has been tested at 23°C, 50°C, 75°C and 100°C.

Diffusivity is the most important factor for blocking heat transfer. Super Therm’s 4-part ceramic formulation works at the speed of climate when it scatters, reflects and blocks solar heat at the surface, eliminating heat load keeping surfaces near ambient.

- Blocks 96.1% of total solar heat (average for UV, visible, and IR combined)

- Tested under ASTM E1269 & E1461-92 for thermal diffusivity and conductivity – 0.256 mm²/s on metal; not plastic (low = better)

- Blocks 99.5% of infrared, the main source (53%) of solar heat

- Achieves thermal insulation without bulk: 250 microns (0.25 mm)

Super Therm’s water-based ceramics work together unlike any other product on the market – two micron sized ceramics are reflective for UV and visual light, the third blocks the infrared solar heat energy and the fourth acts as a non-conductor for emissivity to stop solar heat load making it a safe, high performance and effective energy friendly solution. The ceramics have been tested to block:

- 97% of Ultraviolet Radiation (UV) (3% of total solar heat)

- 92% of Visual Light (Short Wave Radiation) (44% of total solar heat white reflected; black absorbed)

- 99.5% of Infrared (Long Wave Radiation) (53% of total solar heat)

- Block heat load non-conductor – (Emissivity blocks Heat Load)

At the foundation Super Therm® harmonises a unique combination of highly effective aliphatic urethanes for toughness and durability, elastomeric acrylics for elasticity, and resin additives which creates a moisture and ultraviolet barrier. The last polymer additive ensures a slow drying time to prevent cracking as well as adding a silky/matt finish which ultimately gives it the toughness that out performs other paints on the market lasting well over 20 years at a very thin film depth.

The ceramic compounds in Super Therm® are more than a hollow spheres. To have low thermal conductivity other critical properties in the coating include:

- Material composition

- Crystalline structure

- Processing method

- Particle size

- Density and purity

The ceramics/resin combination has been shown to block both heat and fire, withstand elements for over 35 years, endure 160°C temperatures, bends 180° without cracking, and resists water and ultraviolet light in the toughest environments. No other thin-film coating on the market has independently verified this level of full-spectrum heat block performance so you can assured of 100% quality and performance.

Durability

Super Therm® is a life-long solution that’s been tested to withstand over 30 years in field conditions, including intense sun, rain, sand and snow. The durability of the coating is designed for the toughest environments but works in general locations just as well.

- Maintains heat block performance for decades

- Resists UV breakdown, cracking, peeling, fading

- Works when dirty

- No mould and mildew growth

- Self-cleaning properties minimise maintenance

Environmental Credentials

It’s important to have environmental concerns for Super Therm® because it directly addresses one of the biggest global challenges: reducing energy use and carbon emissions without relying on energy-hungry systems. It cuts the need for air conditioning, reduces greenhouse gas emissions at the source. Unlike traditional insulation that absorbs and re-radiates heat, Super Therm® prevents heat loading altogether, making buildings cooler, more resilient, and less dependent on mechanical cooling – even as climate extremes worsen. It offers a powerful, passive solution that lowers energy demand, extends building lifespan, and supports global efforts for net-zero emissions and sustainable development. The coating is also:

- Water-based and non-toxic

- Low VOCs (<67 g/L)

- Eliminates need for bulky insulation or mechanical cooling

- Approved for use in green building programs worldwide including LEED and Cradle-to-Cradle

Third-Party Validations

Independent Testing & Certification

Super Therm’s very high 96.1% Total Solar Reflectance and very minimal energy absorption it has the ultra rare validation of its integrity:

- NASA: Only multi-ceramics solar heat block coating developed with NASA – 35 year review

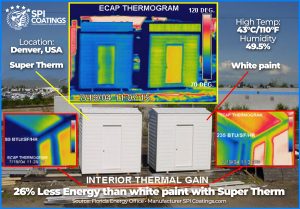

- Florida Energy Office: Tested and verified by the US Energy Authority at 3 locations 20-50% energy reduction

- University of Adelaide: Independent study where Super Therm had no contribution to Urban Heat

- Laboratories: Independently Lab tested in Japan, Russia and USA

- Japan Industry Trials: Over 30 years of industrial data and performance

- ASTM Testing: Full compliance with thermal and solar reflectance testing standards and more

- Global ratings: FM Approved, UL Approved, ABS Marine Approval, MIL-PRF-6799

- Fire testing: NASA, FM Approvals, ABS Fire Resistive, Australian AWTA Lab, ASTM E84

- Corporations: Countless industry results globally including 10.3 million m2 in Japan

- Field Test: 35 year field test between USA and Japan in Kansas

- Super Therm®: World’s most tested thermal insulation & heat reflective coating

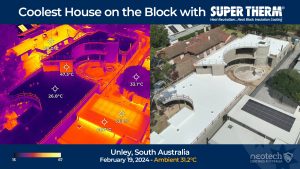

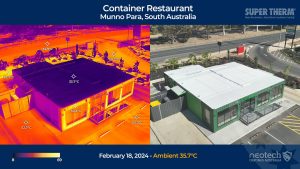

Real-World Results

- Las Vegas International Airport: Reduced jet bridge surface temperatures by over 20°C

- City of Adelaide Cool Roof Trial: Recorded 6°C internal reduction—below ambient temperature, proving Super Therm blocks heat before it enters

- Hundreds of global applications in government, defence, shipping, oil, energy and construction

Industry Uses for Super Therm®

- Aged Care Facilities

- Airports

- Aircraft Hangers

- Agriculture

- Architectural

- Council Buildings

- Data Centres

- Distribution Centres

- Education

- Factories

- Homes/Houses

- Hospitals

- Manufacturing

- Military

- Offices

- Residential

- Shipping Containers

- Sporting Clubs

- Storage Units

- Supermarkets

- Transport

- Warehouses

- Wineries

- Workshops

Super Therm® Specifications

| Total Solar Heat Block | 96.1% |

| Solar Reflectance Index (SRI) | 105 |

| Heat Block Factor | 0.98 |

| Litres to Weight ratio | 1.53 – very high |

| Emissivity | .91 |

| Solar Absorption | .039 |

| Reflectance CRRC | 83 or 95 when using all IR points |

| Colour | Egg Shell White |

| Tintable (light colours) | Yes |

| Texture | Silky Matt |

| Water Based | Yes |

| Maximum Surface Temp. Application | 65°C |

| Minimum Surface Temp. Application | 5°C |

| Maximum Heat Tolerance | 149°C |

| Spread Rate per litre | 2.2m2 @ 450µ wet |

| Thickness in Microns (µ) Wet | 450µ |

| Thickness in Microns (µ) Dry | 238µ |

| Coat System | 1 Coat |

| Primer Required (most surfaces) | No |

| Application | Airless, Brush, Roller |

| Primary Cure | 6 hours |

| Final Cure | 21 days |

| Expected Lifespan | 30+ Years |

| Shelf life | Up to 5 years if unopened at <30°C storage |

| Maintenance Program Required | No |

| Viscosity | 128 K.U. (Heavy) |

| Weight Dry per m2 | 342 grams |

| Fire Rating | Class “A” by NASA, AWTA, UL, E84 |

| Structural Steel Fire Curve | ASTM E119 – 25 minutes at 1093°C |

| Acoustics Rated | Yes – 50-68% |

| Condensation Control | Yes |

| Safety Data Sheets | Yes |

| Formulation | 4 Micron sized ceramics |

| Binding | Self-cross linking Acrylic blend |

| Solids by Weight | 69% |

| Solids by Volume | 57% (+/-2%) |

| Flexibility | Bend around 1/4″ |

| Elongation | 100% |

| Impact | 511 cm kg |

| Low VOC grams per litre | 67 |

| Perm Rating – Water Vapour 0.25mm | 8.8 – ASTM E96 |

| Mean Permeance (ug/N.S) | 457.6 |

| Salt Spray | 2000 hours |

| Australian Warranty | 20 Years* |

| ISO Current | Yes |

| Year Developed | 1989 |

| Used Australia since | 1995 |

| Manufactured | Kansas, USA |

| NASA Development | Yes |

| EPA Approved | Yes |

| FM Approved | Yes |

| UL Approved | Yes |

| ABS Approved | Yes |

| US Energy Authority Tested | Yes |

| Thermal Conductivity | C177 blocking heat transfer |

| Fracture toughness | ASTM E1737 |

| Certifications | UL, FM, ABS, Energy Star, California Bureau of Home Furnishings and Thermal Insulation, ICC #21-25, CRRC, USGBC, Coast Guard, IMO, DNV, JIS (Japanese Institute for Standards) for blocking 92% of visual and 99% of infrared radiation, USDA and China Marine centre for testing. |

0.0 m2 / 2.4 m2 / litre = 0.0 litres / 18.9 litres per 5 Gallon pail @ 250 microns = 0.0 pail + 0.0% for profile = 0.0 pails / 0.0 litres * Profile % based on corrugations and like profiles 20% extra as a guide. Brick mortar 15% extra. 10% for shipping containers profiles.

How Super Therm® Compares

| Features | Super Therm® | White Paint / Reflective Coatings | Bulk Insulation (Fibreglass, etc.) |

|---|---|---|---|

| Blocks Total Solar Heat (%) | 96.1% | 60–85% (short-term) | 0% (absorbs heat then slows flow) |

| Infrared Heat Blocking (%) | 99% | ~30–50% | 0% |

| Works Without Absorbing Heat | Yes (Heat Factor) | No (K-value) | No (R-Value) |

| Dry Thickness | 0.25 mm | 0.5–2 mm | 50–200 mm |

| Lab Tested | 23, 50, 75 & 100°C | 25°C | 24°C |

| Acoustic Testing | Yes 50-68% | None | Varies |

| Stops Heat at the Surface | Yes | Partially | No |

| Protects the Envelope | Yes | Yes | No |

| Maintenance Frequency | No | Maintenance required | No |

| Works when Wet | Yes | Yes | No |

| Tested Lifespan | 30+ years | 2–10 years | Varies |

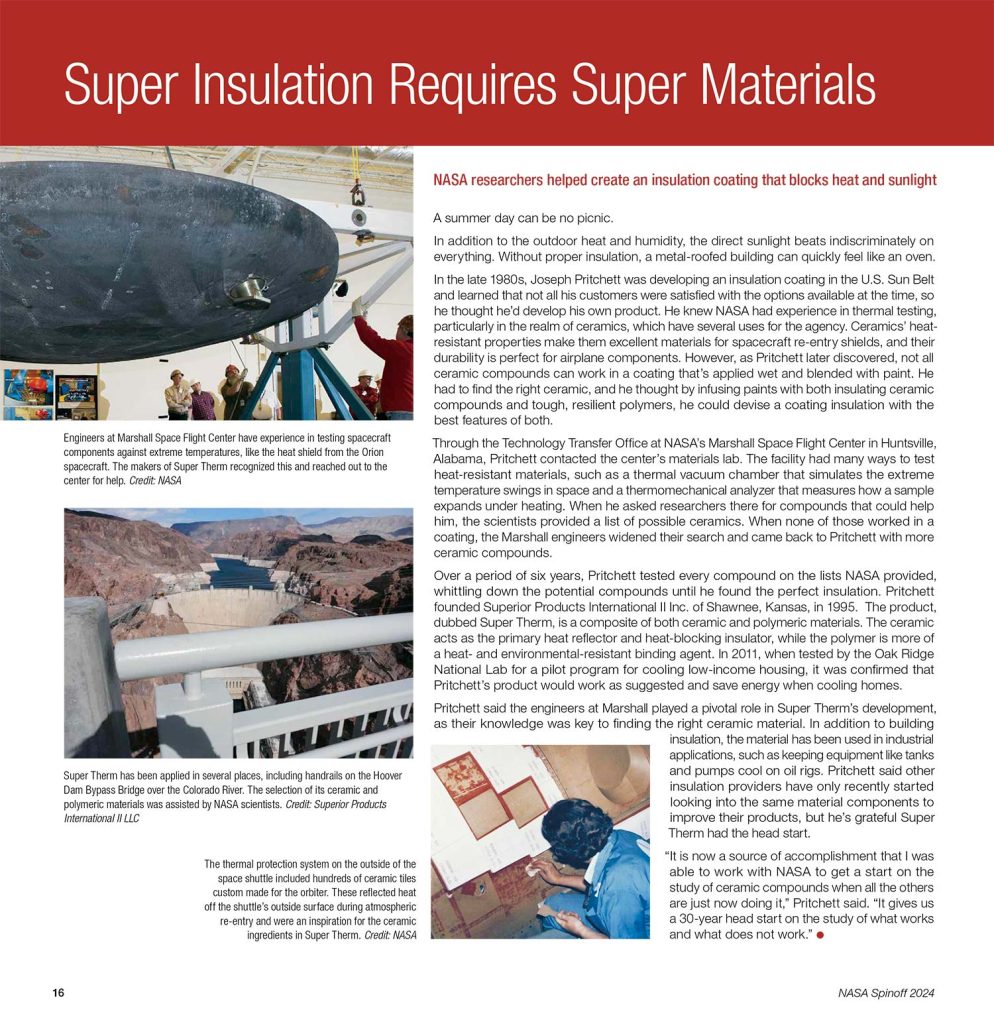

Historical insulation coating development with NASA

Super Therm® is the only multi-ceramic insulation coating developed with NASA from 1989-1995. J.E. Pritchett, President of SPI II Inc, the manufacturers, created an award-winning, water-based coating composed of four ceramic compounds embedded in a foundation of a tough resin system.

NASA is happy to talk about Super Therm® with a 35 year review article (see the Super Therm® story and science). The physics of ceramics highlights they melt at thousands of centigrade unlike metal, aerogels, plastics and fibreglass and ceramics do not release poisonous chemicals, they are a natural insulator with low conductivity.

After 6 years of development and testing of more than 4000 different kinds of ceramic components, 3 ceramics with the greatest ability of solar radiation reflection and the smallest heat conductivity were ultimately selected that could be put into a wet base, dry and work to maximum effect. The ceramics used in Super Therm® do not conduct heat It is a thin insulation thermal coating. After testing up to 100°C the performance was the same. Super Therm® blocks heat load and NASA understands the science and physics behind this coating.

Simple to Apply, Designed to Last

- Spray, roll, or brush apply on roofs, walls, tanks, or containers and other surfaces

- Apply low wind days if airless with 50% overlap or 2 generous coats by brush or roller

- Dries to a tough ceramic shield at just 250 microns/0.25mm (business card thickness)

- Designed to last for decades with minimal maintenance.

Confidence and Certainty with Super Therm®

Super Therm® delivers unmatched confidence, certainty, and security by reducing project risk and ensuring long-term performance. With over 35 years of proven field success, it is backed by independent lab testing and supported through certified application partners or DIY options. Its proven track record gives customers the assurance that Super Therm® is a solution they can trust to perform exactly as promised.

Beyond performance, Super Therm® offers a risk-free investment with minimal disruption—easy to apply over existing surfaces without structural changes. It’s a one-time application that delivers decades of protection. Trusted by governments, defence, and major industries in some of the harshest climates worldwide like Saudi Arabia, Australia, Japan, Nevada. Super Therm® has proven it can thrive where reliability is non-negotiable.

What Super Therm® Means For You:

- 35+ years of proven field performance

- Australia’s highest total solar heat block at 96.1%

- Certified application partners and full independent testing

- Applies directly to surfaces – no major modifications

- Long lifespan from a single application

- Used by governments, defence, and industry in extreme environments

- Future-proof your buildings against rising energy prices and climate extremes.

- Reduce strain on air conditioning systems, extending their life.

- Contribute to lower CO₂ emissions with a passive, zero-energy solution.

Get a Quote or Book a Consultation

Ready to Future-Proof Your Building? Block heat, cut energy bills, and protect your assets for decades with Super Therm®. Contact NEOtech Coatings Today